Method for producing grading soy protein

A technology of soybean protein and defatted soybean flour, which is applied in the field of high-purity production of 7S globulin and 11S globulin with low phytic acid content, and can solve the problems of soybean protein functional property decline, reduction of mineral element utilization rate, and limitation of Deak method, etc. , to achieve the effect of ensuring nutritional value and functional properties, strong gel forming ability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

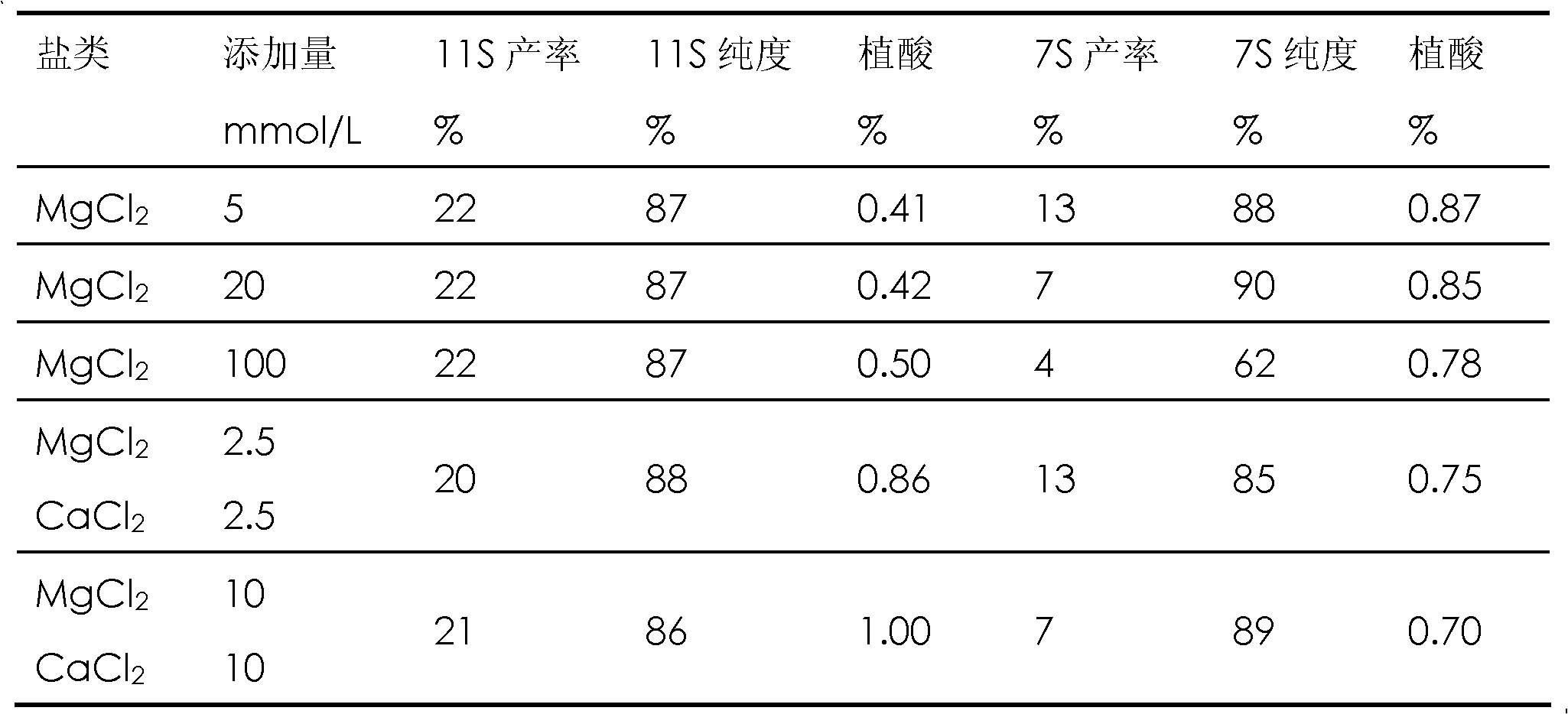

[0028] The defatted soybean meal (NSI=91, protein content 49%) was pulverized and passed through a 60-mesh sieve to obtain defatted soybean meal, mixed with water in a mass ratio of 1:15, adjusted to 8.0 with NaOH, and extracted for 1 hour, and centrifuged to obtain defatted soybean protein extraction. liquid. The pH of the defatted soybean protein extract solution is adjusted to 6.8 with a concentration of 2mol / L of hydrochloric acid, and sodium bisulfite is added to control the concentration of sodium bisulfite in the defatted soybean protein extract solution (after adjusting the pH) to be 10mmol / L; And respectively add magnesium chloride, control the concentration of magnesium chloride in defatted soybean protein extract (after adjusting pH) to be 5, 20, 100mmol / L respectively; or the mixture of calcium chloride and magnesium chloride, control calcium chloride and magnesium chloride in defatted soybean The concentration in the protein extract (after adjusting the pH) is all...

Embodiment 1

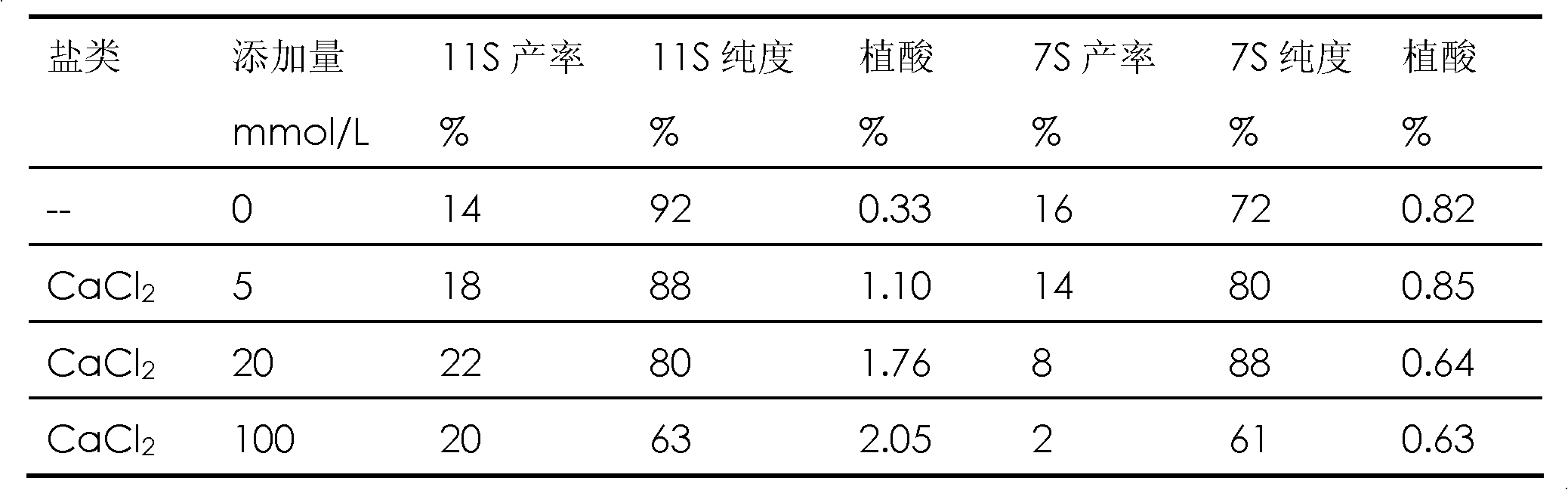

[0037] The defatted soybean meal (NSI=91, protein content 49%) was pulverized and passed through a 60-mesh sieve to obtain defatted soybean meal, mixed with water in a mass ratio of 1:15, adjusted to 8.0 with NaOH, and extracted for 1 hour, and centrifuged to obtain defatted soybean protein extraction. liquid. The pH of the defatted soybean protein extract solution is adjusted to 6.8 with a concentration of 2mol / L of hydrochloric acid, and sodium bisulfite is added to control the concentration of sodium bisulfite in the defatted soybean protein extract solution (after adjusting the pH) to be 10mmol / L; Add calcium chloride, control the concentration of calcium chloride in defatted soybean protein extract (after adjusting pH) to be 5, 20, 100mmol / L respectively; Repeat the above steps, and carry out laboratory analysis to the product of gained, the results are shown in Table 2 .

[0038] Table 2

[0039]

[0040] Comparing Table 1 and Table 2, it can be seen that compared w...

Embodiment 2

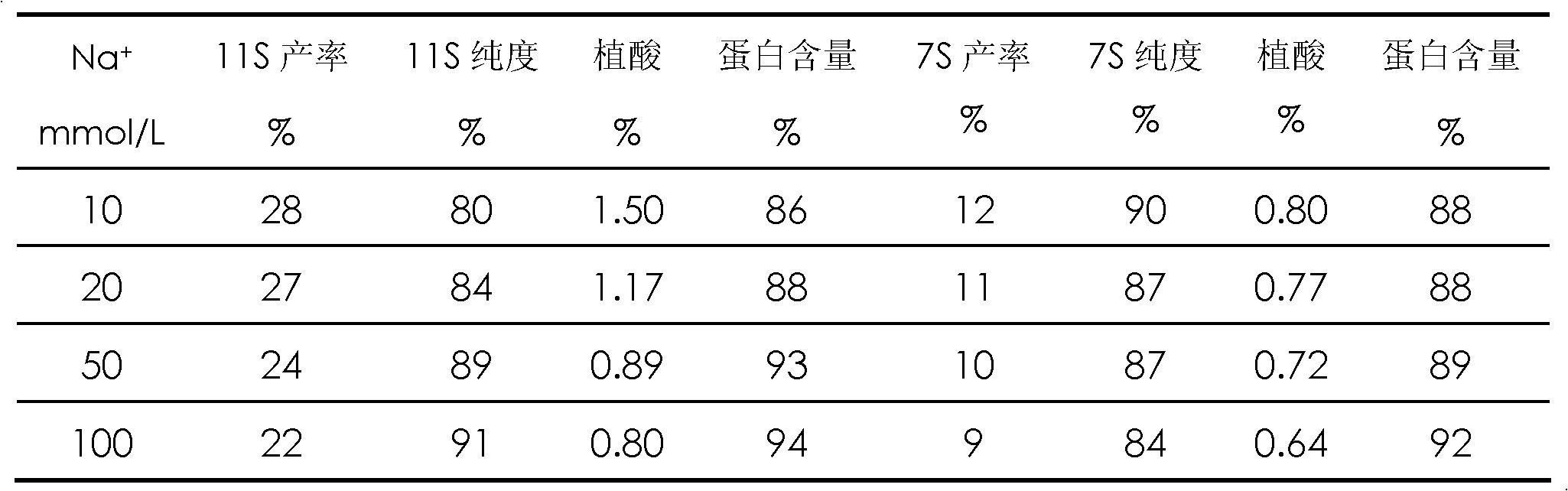

[0043] The defatted soybean meal (NSI=91, protein content 49%) was pulverized and passed through a 60-mesh sieve to obtain defatted soybean meal, mixed with water in a mass ratio of 1:10, adjusted to 7.5 with NaOH, and extracted for 1.5 hours, and centrifuged to obtain defatted soybean protein extraction. liquid. Adjust pH to 5.8 with hydrochloric acid, add sodium bisulfite and calcium chloride, respectively control the concentrations of sodium bisulfite and calcium chloride in the defatted soybean protein extract (after adjusting the pH) to be 10mmol / L and 5mmol / L; Sodium chloride was added to control the concentration of sodium ions in the defatted soybean protein extract (after pH adjustment) to be 20, 50 and 100 mmol / L, respectively. After all the extracts were stirred at room temperature for 1 hour, they were centrifuged with a batch centrifuge (3000 g) to separate a soluble fraction containing 7S globulin and an insoluble fraction containing 11S globulin. The pH of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com