Hose coupling

A coupling and hose connection technology, applied in the direction of couplings, dairy products, milking equipment, etc., can solve the problems of high pollution of emulsion hoses, time and energy consumption, operator pollution, etc., and achieve a simple overall structure design , simple structure and high mechanical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

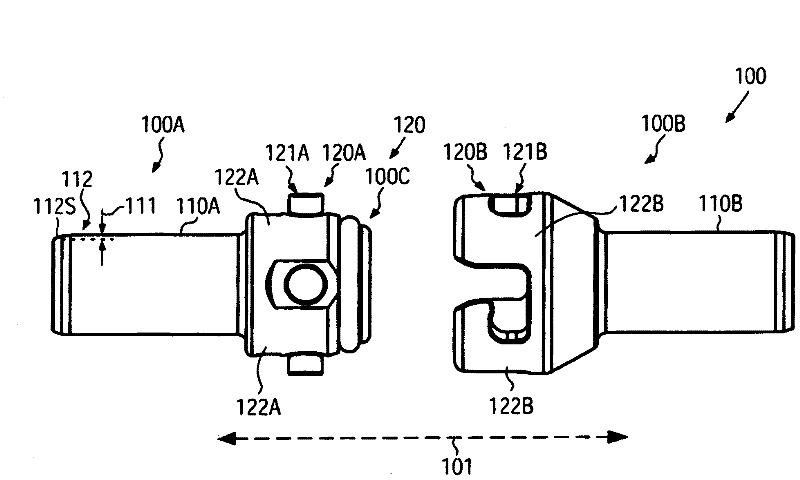

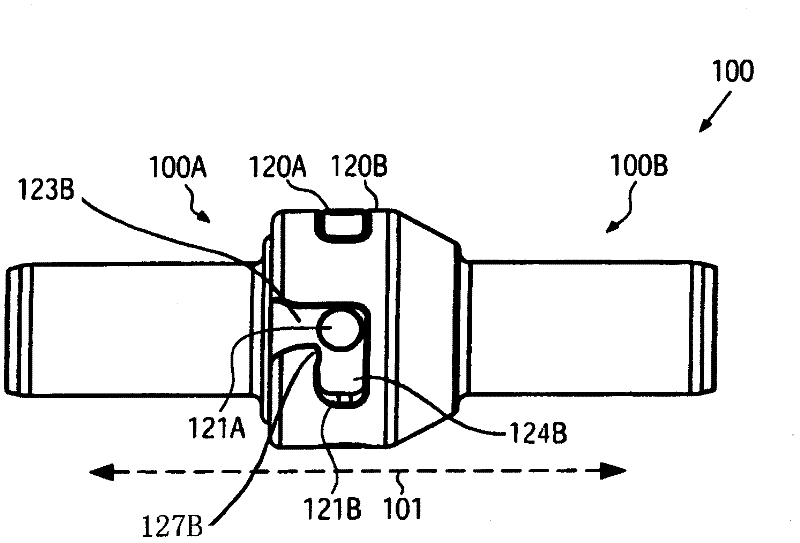

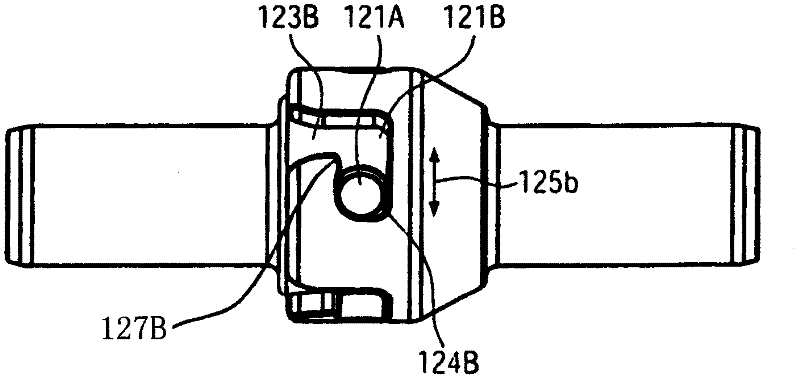

[0033] Figure 1a An overall view of the hose coupling 100 is shown schematically in side view. The hose coupling 100 includes a first coupling part 100A and a second coupling part 100B. In the illustrated embodiment, the coupling part 100A is provided with a hose connection area 110A and the coupling part 100B is provided with a hose connection area 110B onto which respective hose pieces can be pushed. The hose coupling 100 is suitable, for example, to be connected to any hose, and the size of the hose coupling 100 is suitable for the corresponding hose, that is, when the hose coupling 100 is used as a hose with the same inner diameter, the same outer diameter and the like. When connecting between two hose pieces of material properties, the respective hose connection areas 110A and 110B will have approximately the same structural design so that the hose pieces involved can be pushed into the hose connection areas 110A and 110B and is secured mechanically due to the inherent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com