Working medium filling device and method of loop circuit heat pipe at medium and low temperature

A zone loop and working medium technology, applied in the field of heat pipe working medium filling device, can solve the problem of insufficient quality of filling workers, and achieve the effect of avoiding repeated inflation, reducing errors and speeding up the cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will now be described in detail in conjunction with the accompanying drawings.

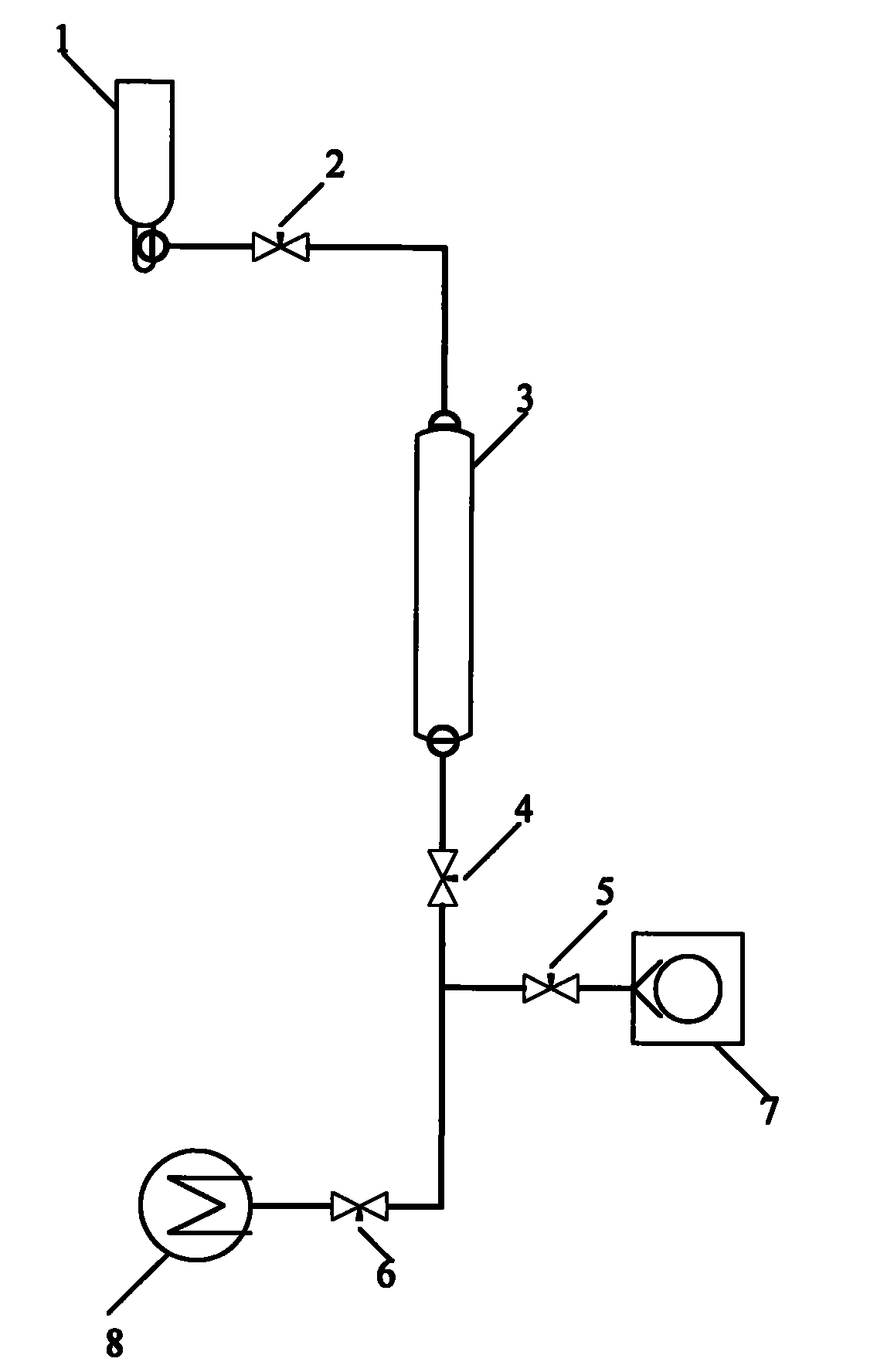

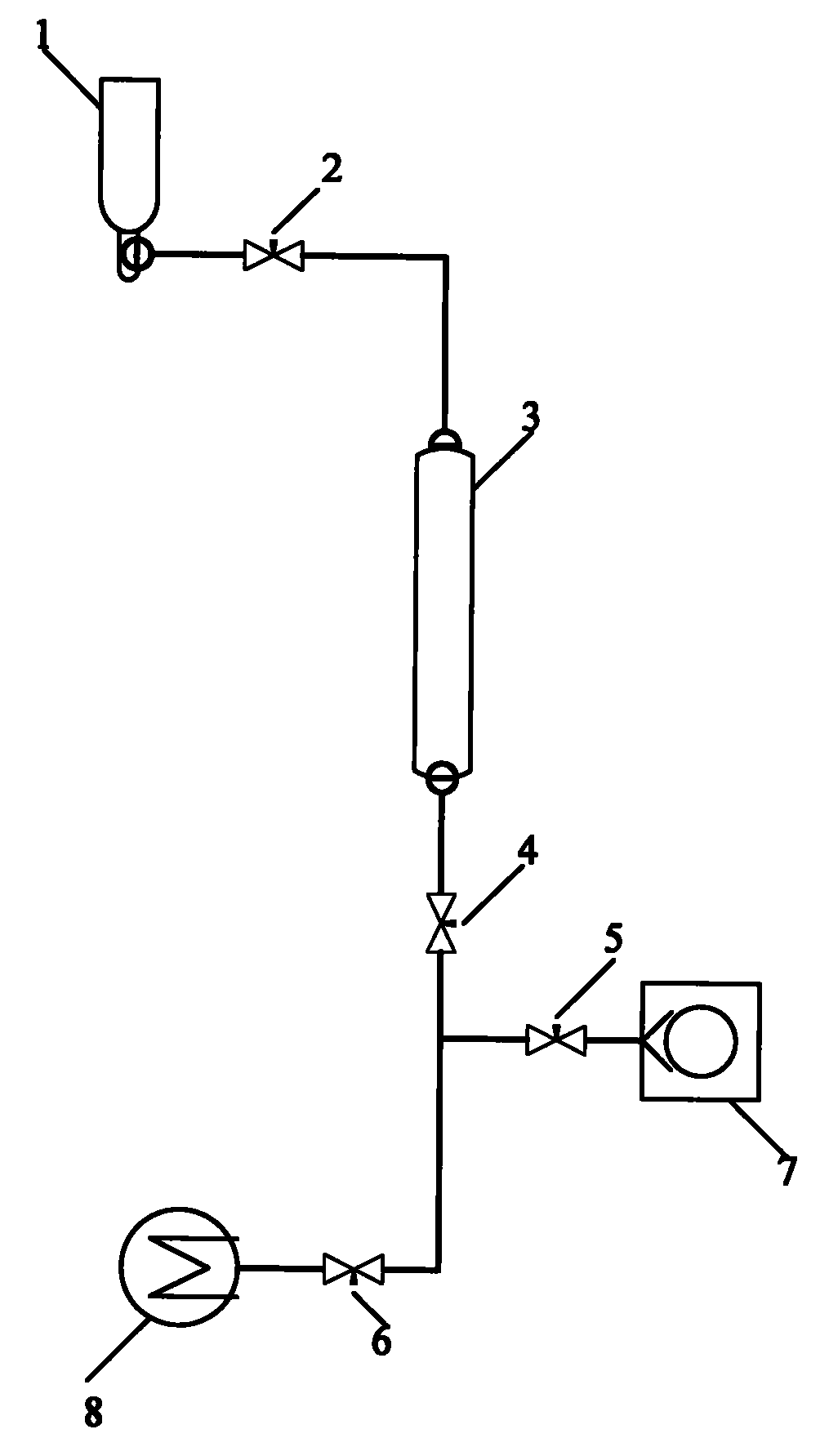

[0014] Such as figure 1 As shown, it is an overall structural diagram of the present invention, including: an inverted steel cylinder 1 with a gas-liquid two-phase working medium, a first valve 2, a section of transparent quartz glass tube 3, a second valve 4, a third valve 5, a first valve Four valves 6, a set of vacuum unit 7, a loop heat pipe 8. During the specific implementation, we use a ethane cylinder with a size of 40L and a purity of 99.99%. The first valve is a stainless steel metering valve purchased from Swagelok, and the second, third and fourth valves are all purchased from Swagelok. The stainless steel needle valve, the self-made quartz glass tube requires a length of 1000mm, an inner diameter of 6mm, and an outer diameter of 25mm, to ensure that the pressure at room temperature is >5MPa, and the scale must be evenly engraved on the tube wall. The vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com