Underground dust-removing foam generator and foam dust-removing equipment

A technology of foam generator and dust removal equipment, which is applied in mining equipment, dust prevention, chemical instruments and methods, etc. It can solve problems such as nozzle blockage, foaming net damage, and low dust removal efficiency, and achieve the effect of avoiding easy blockage and foaming Good, well-designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

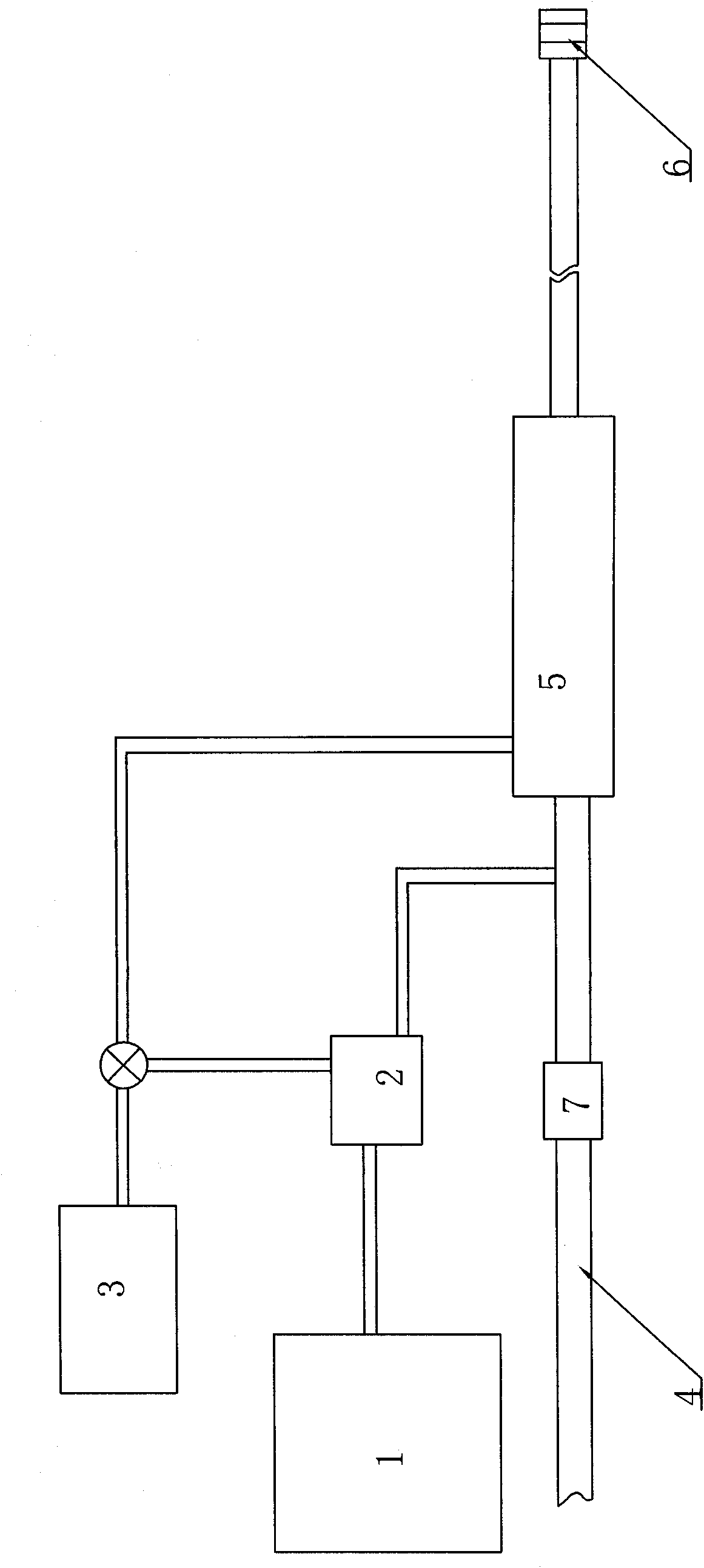

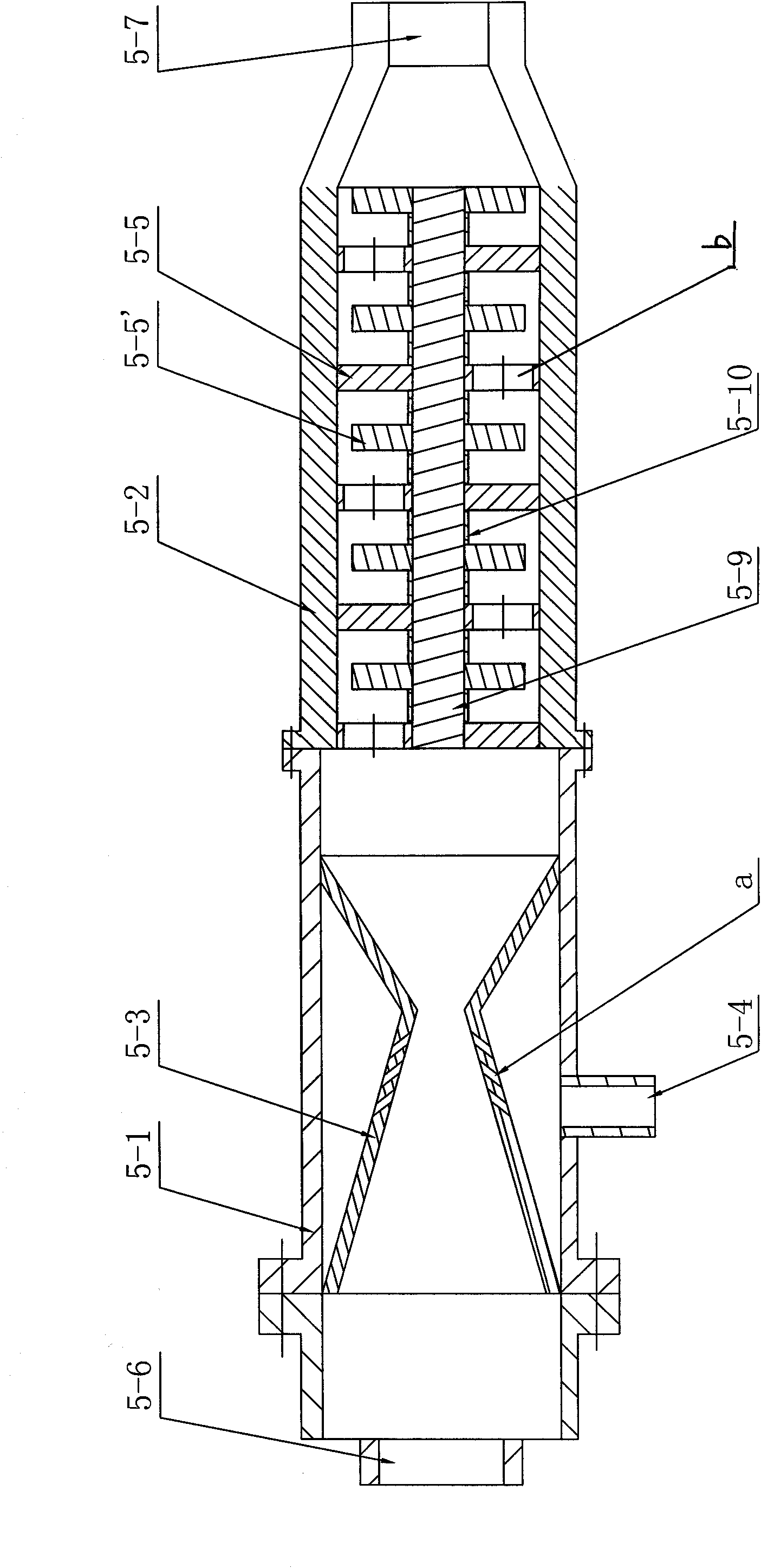

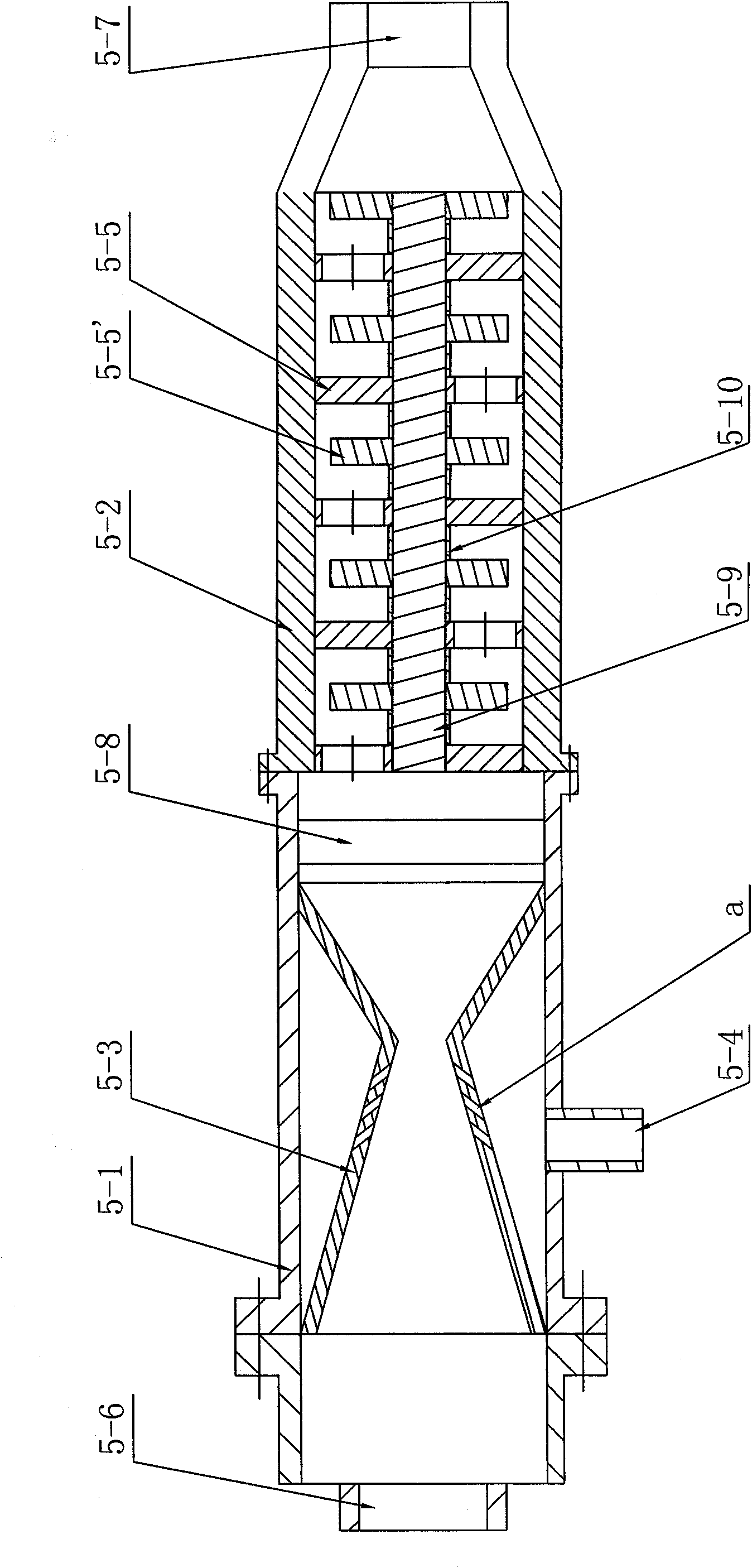

[0018] Such as figure 1 As shown, the foam dedusting equipment of the present invention includes a foaming agent liquid storage tank 1, a quantitative addition pump 2, an air compressor 3, a water inlet pipe 4, a foam generator 5, a foam spray nozzle 6, a filter 7 and a connecting pipeline , a flow regulating valve and a check valve (not shown) are arranged on the pipeline as required. Wherein, foaming agent liquid storage tank 1 communicates with quantitative addition pump 2 by pipeline, foaming agent is housed in foaming agent liquid storage tank 1, and the output of foaming agent in foaming agent liquid storage tank 1 is controlled by quantitative addition pump 2 control. The air compressor 3 communicates with the quantitative addition pump 2 and the foam generator 5 respectively through the intake pipeline. In this embodiment, a three-way valve is installed on the intake pipeline, and the airflow of the intake pipeline is divided into two branches The airflow of one bran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com