Building construction all-steel mold plate and manufacturing and assembling method thereof

A technology of building construction and steel formwork, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc. It can solve the problems of joints such as grout leakage, and achieve tight joints, convenient handling, and easy assembly and disassembly. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

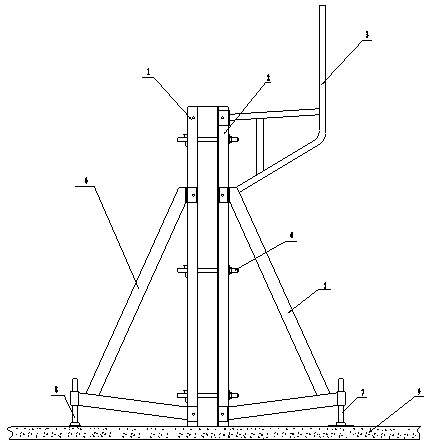

[0059] Example: figure 1 As shown, the panels of plates 1 and 2 are made of 6 mm thick hot-rolled steel plates, and the back of the panels is welded with a number of reinforcing ribs, and the reinforcing ribs are rectangular tubes. The two flat plates 1, 2 are connected, the distance between the two flat plates 1, 2 is the thickness of the wall, the outer sides of the two flat plates 1, 2 are supported by the oblique supports 5, 6, and the two ends of the oblique supports 5, 6 The stiffeners of the head and the plate are connected by bolts, the support columns 7 and 8 of the oblique supports 5 and 6 are supported on the ground, the operating platform frame 3 is installed on the outside of the plate 2 and above the oblique support 5, and the connection between the operating platform frame 3 and the plate 2 The ribs are fixed by bolts.

[0060] The male angle is connected with the flat plate, that is, the connection state of flat plate-male angle-flat plate is formed. The flat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com