Electronic jacquard card and drive board thereof

A driving board and flower pillow technology, which is applied in patterned boards, jacquard machines, textiles, etc., can solve the problems of many fault points, increased faults, and high cost, and achieve the effects of not being easily deformed and bent, improving the efficiency of looms, and being easy to process in batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

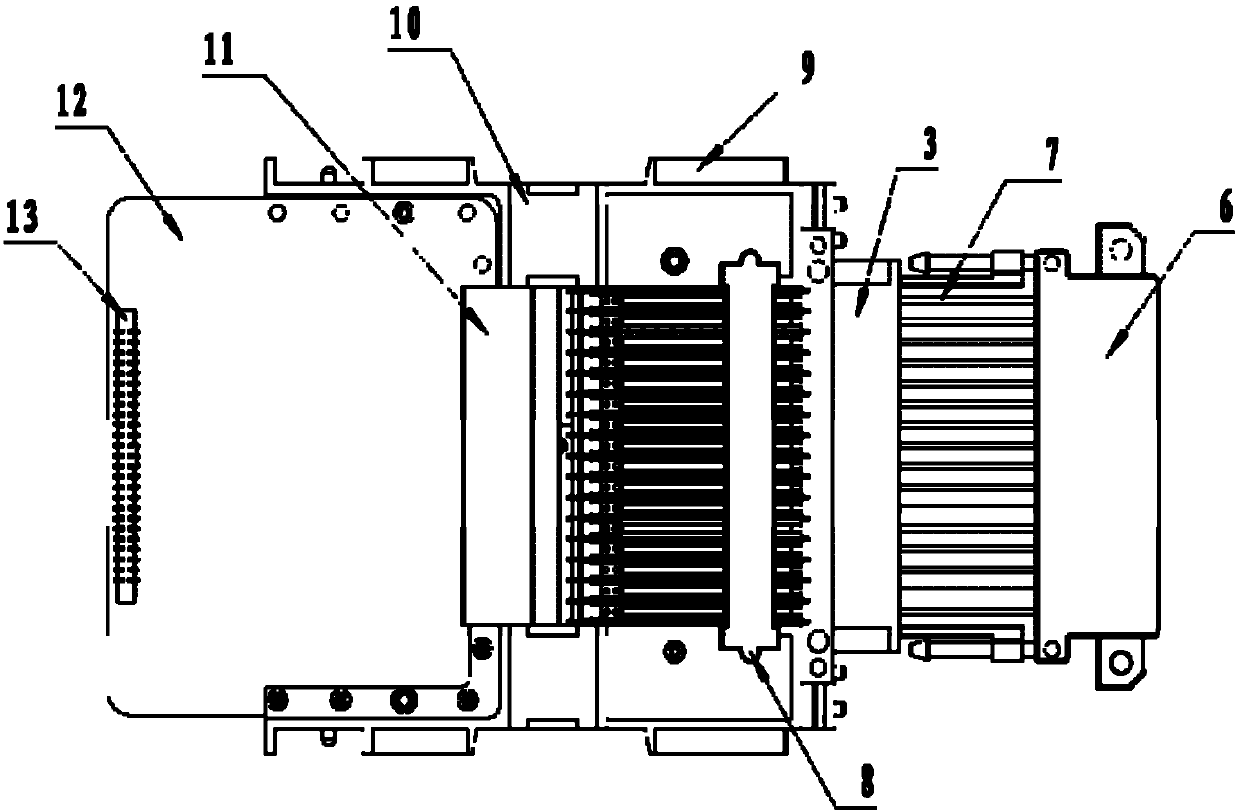

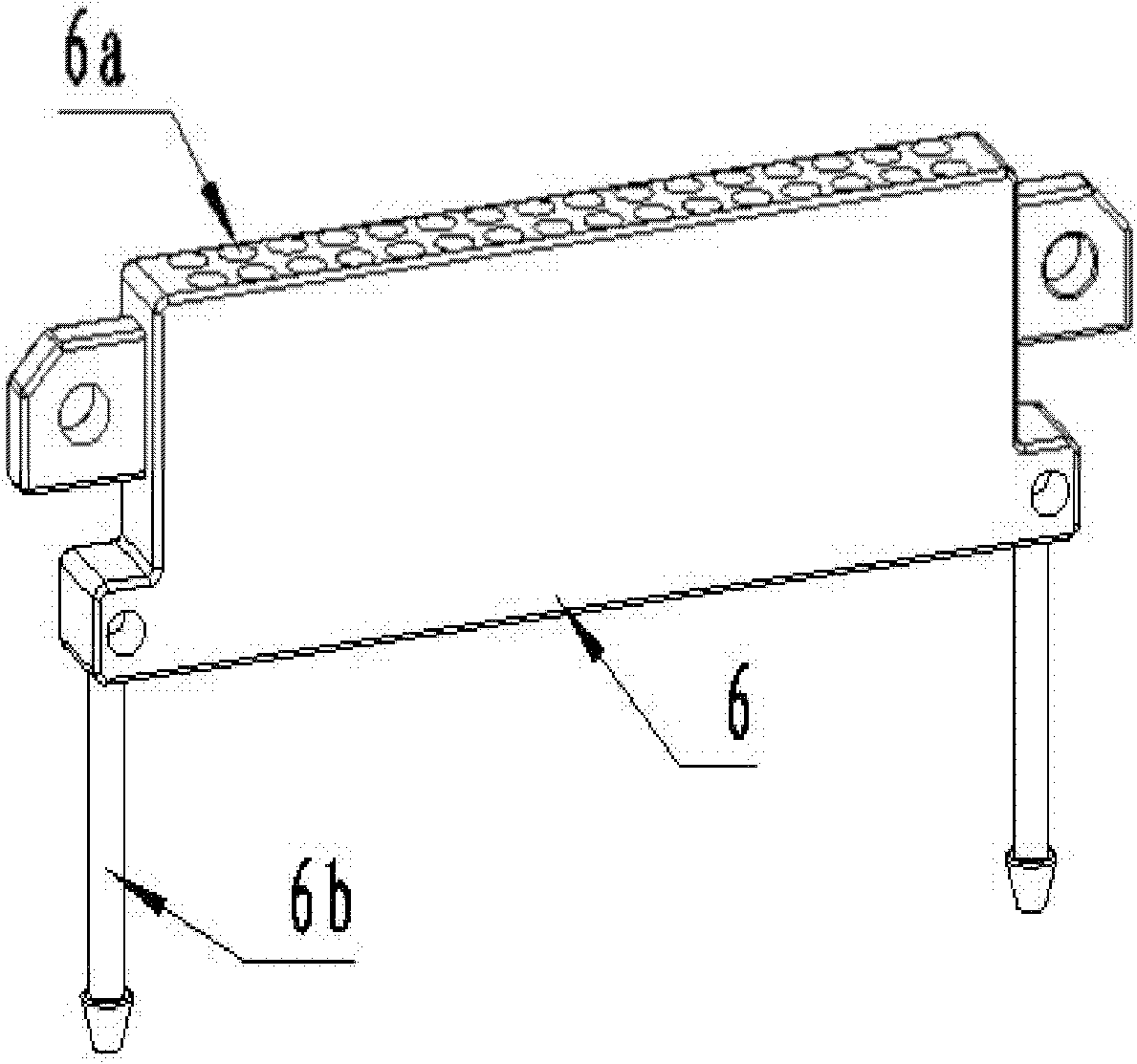

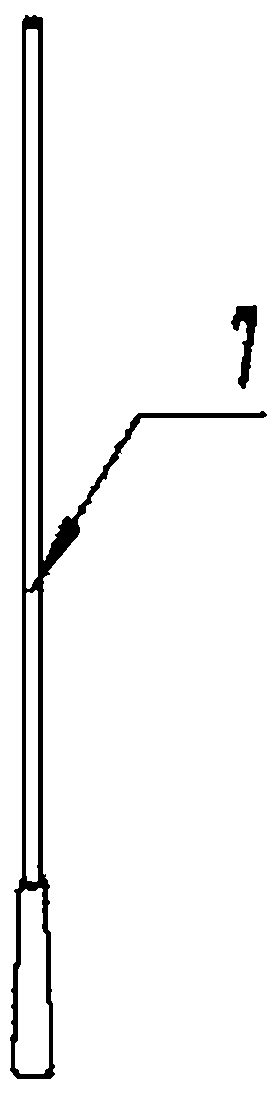

[0066] Such as figure 1 As shown, it is a structural schematic diagram of an embodiment of the electronic flower pillow driving board of the present invention. The electronic flower pillow driving board of this embodiment includes a driving board frame, an electromagnetic needle limit frame 3 installed at the front end of the driving plate frame, and an electromagnetic needle limiter. Frame 3 is movably connected to the push pin holder 6, the push pin 7 installed on the electromagnetic needle limiter 3 and the push pin holder 6, the electromagnetic needle shaft 4 installed on the drive plate frame, and one end is hinged on the electromagnetic needle shaft 4 The other end is installed on the electromagnetic needle 1 on the electromagnetic needle limit frame 3, the permanent magnet 2 that is matched with the electromagnetic needle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com