Solvent-resistant and hydrolysis-resistant urethane resin adhesive

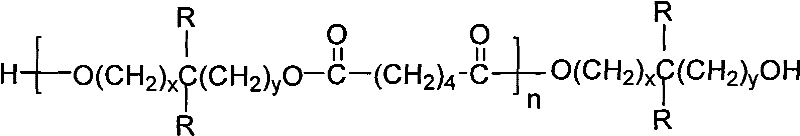

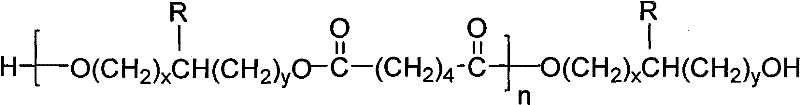

A polyurethane resin, hydrolysis-resistant technology, used in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve problems such as poor adhesion, poor compatibility, and poor resin strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Raw material name Weight (kg)

[0030] Polyester polyol (number average molecular weight 1500, self-made) 200

[0031] PPG3000 300

[0032] EG (ethylene glycol) 29.6

[0033] BG (butanediol) 12.3

[0034] NPG (octylpentylene glycol) 7

[0035] MDI (phenylmethane-4,4`-diisocyanate) 230

Embodiment 2

[0037] Raw material name Weight (kg)

[0038] Polyester polyol (number average molecular weight 2000, self-made) 225

[0039] PPG2000 275

[0040] EG (ethylene glycol) 48.3

[0041] NPG (octylpentylene glycol) 9

[0042] MDI (diphenylmethane-4,4`-diisocyanate) 279

[0043] The preparation method of Example 1 and Example 2 is solution polymerization, using methyl ethyl ketone as solvent, the viscosity is about 20000-30000mPa·s when the solid content is 40%, the sizing is direct coating, bonding, and drying at 80°C.

[0044] Dry the resin solution at 80°C and cut it into strips with a thickness*width*length of 2*20*150mm. Solvent resistance: the adhesive products of the products obtained in the two examples and Bayer DP9380AU will not be shelled in methyl ethyl ketone for 12 hours. combined see table 1

[0045] Table 1

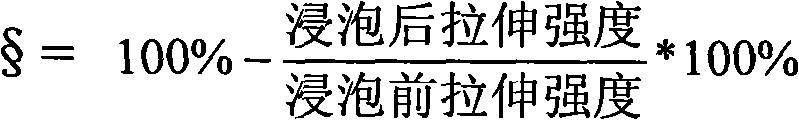

[0046] Loss Rate§

[0047] To sum up, the solvent-resistant and hydrolysis-resistant polyurethane resin adhesive provided by the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com