Preparation method for synthesizing high-performance polycarboxylic acid water reducing agent by undergoing one-step amidation reaction

A technology of amidation reaction and polycarboxylic acid, which is applied in the specific preparation field of synthesizing polycarboxylic acid high-performance water reducer by one-step amidation reaction, can solve the problems of poor dispersion retention and achieve safety and environmental protection in the preparation process, reduce the The effect that the production cost and performance are not affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

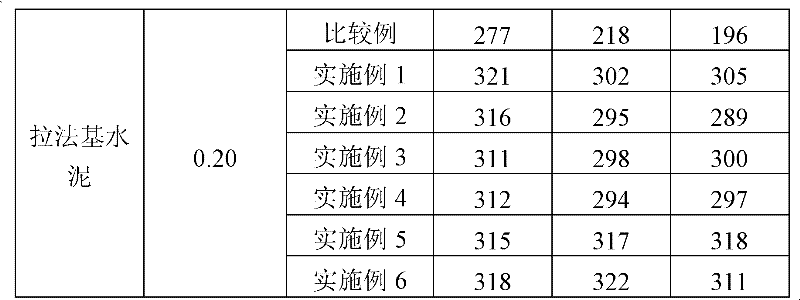

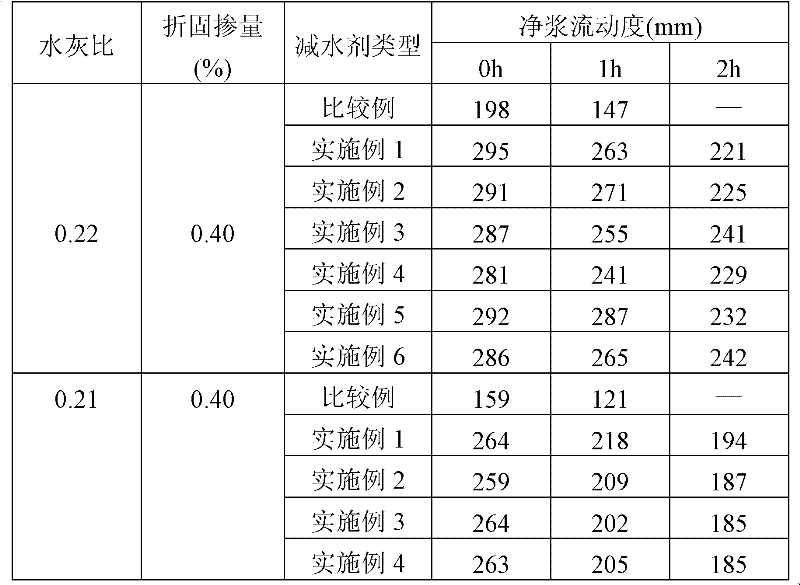

Examples

Embodiment 1

[0020] The aqueous solution of 18.62g polyacrylic acid (concentration 58%) is joined in the reactor, vacuumizes and removes the moisture in the system at 35 ℃, then successively adds 100g amino-terminated polyoxyethylene ethers (molecular weight is 2000) in the reactor, 10g of p-toluenesulfonic acid, add 22.16g of cyclohexane when the temperature rises to 80°C, continue to heat up to 145°C for amidation reaction, separate the water obtained during the reaction, and remove it by vacuuming after 6 hours of reaction Cyclohexane, when the temperature is lowered to 40°C, use 12g of 30% sodium hydroxide solution to neutralize to a pH value of 7, cool to 30°C to obtain the reaction product polyacryloyl polyoxyethylene ether amine, and finally add 281.87g of water Diluted to obtain a concentration of 30% polycarboxylate water reducer.

Embodiment 2

[0022] The polycarboxylate superplasticizer with a concentration of 30% obtained in Example 1 was stored at 5° C. for 20 days, and its implementation effect was measured.

Embodiment 3

[0024] An aqueous solution of 26.33g polymethacrylic acid (concentration 49%) was added in the reactor, and the moisture in the system was removed by vacuuming at 70°C, and then 150g amino-terminated polyoxyethylene ether (molecular weight was 3000 ), 2.3g concentrated sulfuric acid (concentration 98%), add 13.03g toluene when the temperature rises to 100°C, and continue to heat up to 160°C to carry out amidation reaction. Vacuumize to remove toluene, neutralize with 39.2g of 10% potassium hydroxide solution to pH 6 when the temperature is lowered to 60°C, cool to 25°C to obtain the reaction product polyisoacryl polyoxyethylene ether amine, and finally Adding 216.98g of water to dilute to obtain a concentration of 40% polycarboxylate water reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com