Preparation method for synthesizing high-performance polycarboxylic acid water reducing agent by undergoing one-step amidation reaction

The technology of amidation reaction and polycarboxylic acid is applied in the specific preparation field of synthesizing polycarboxylic acid high-performance water-reducing agent by one-step amidation reaction, which can solve the problems of poor dispersibility maintenance and the like, and achieves safe and environmentally friendly preparation process and reduces Production cost, sufficient mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

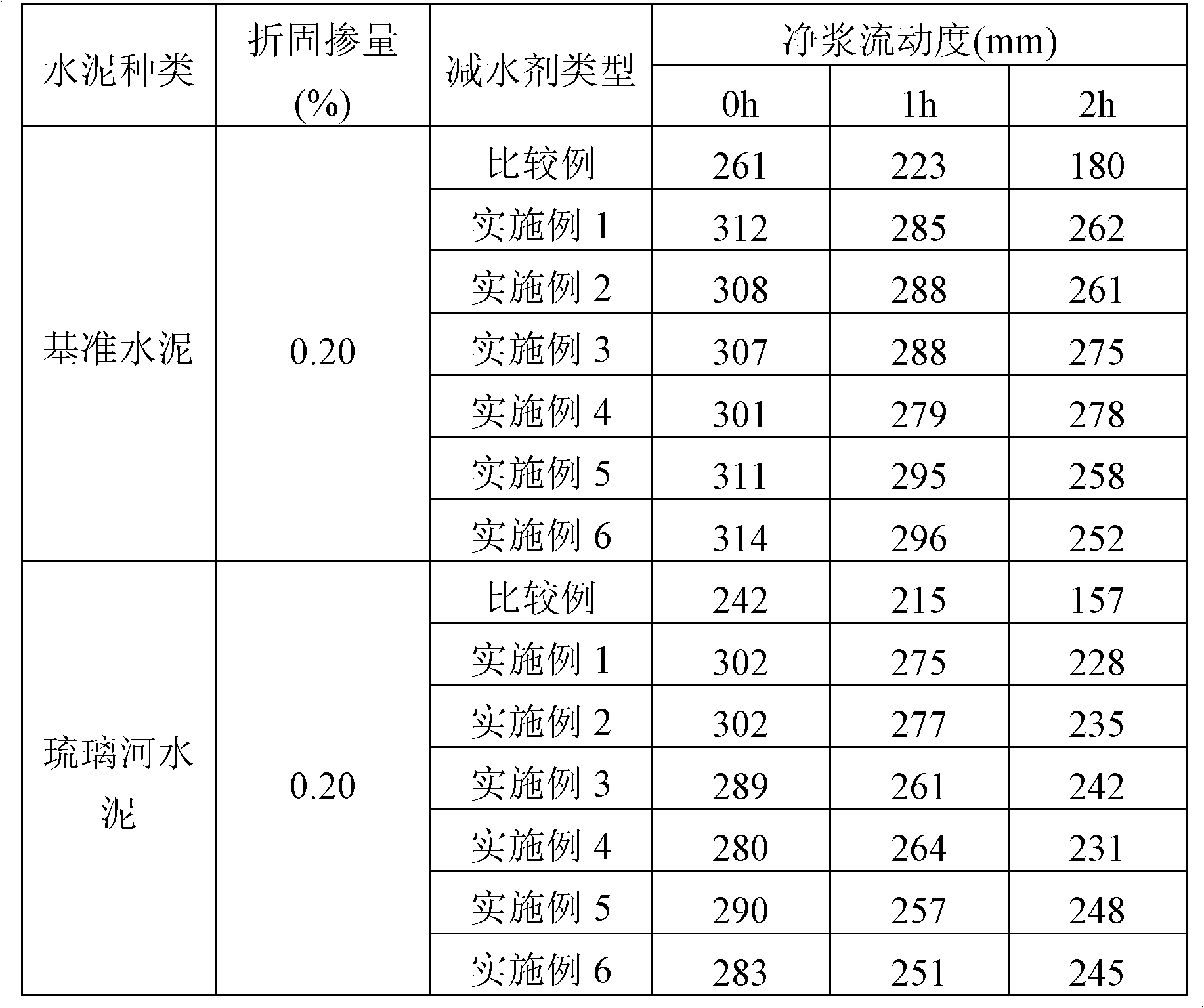

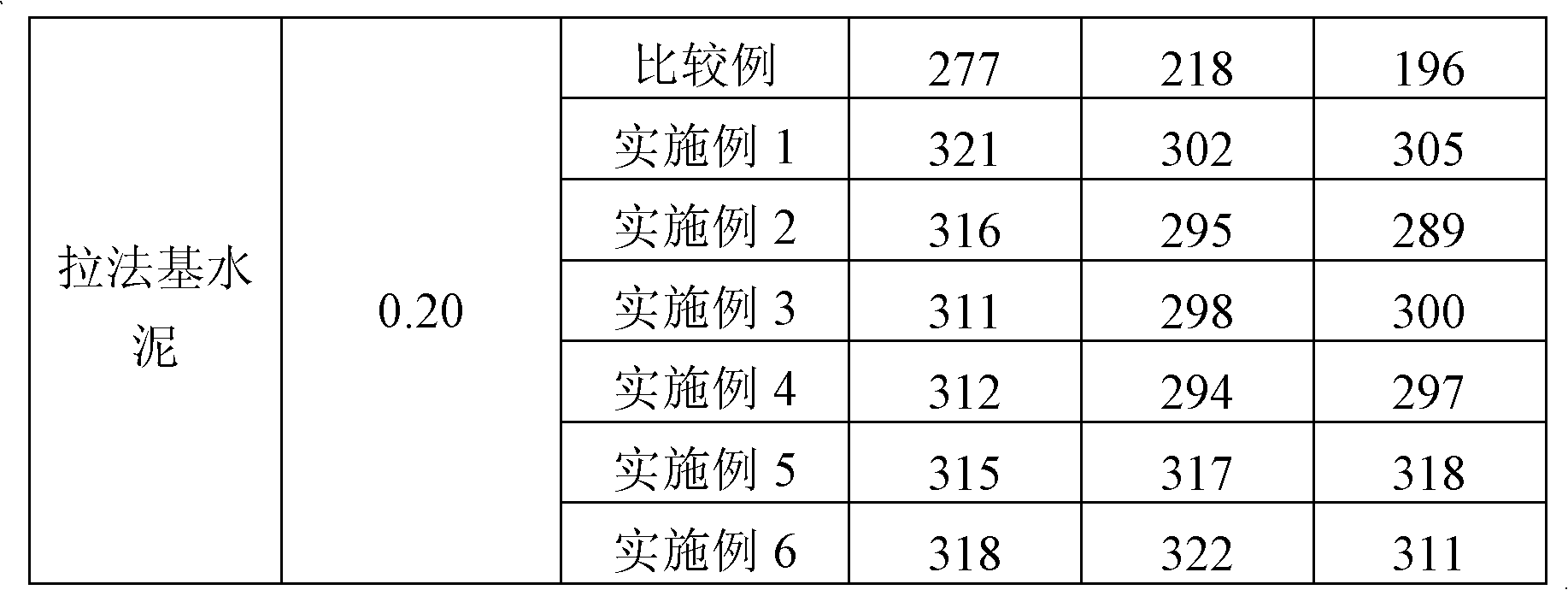

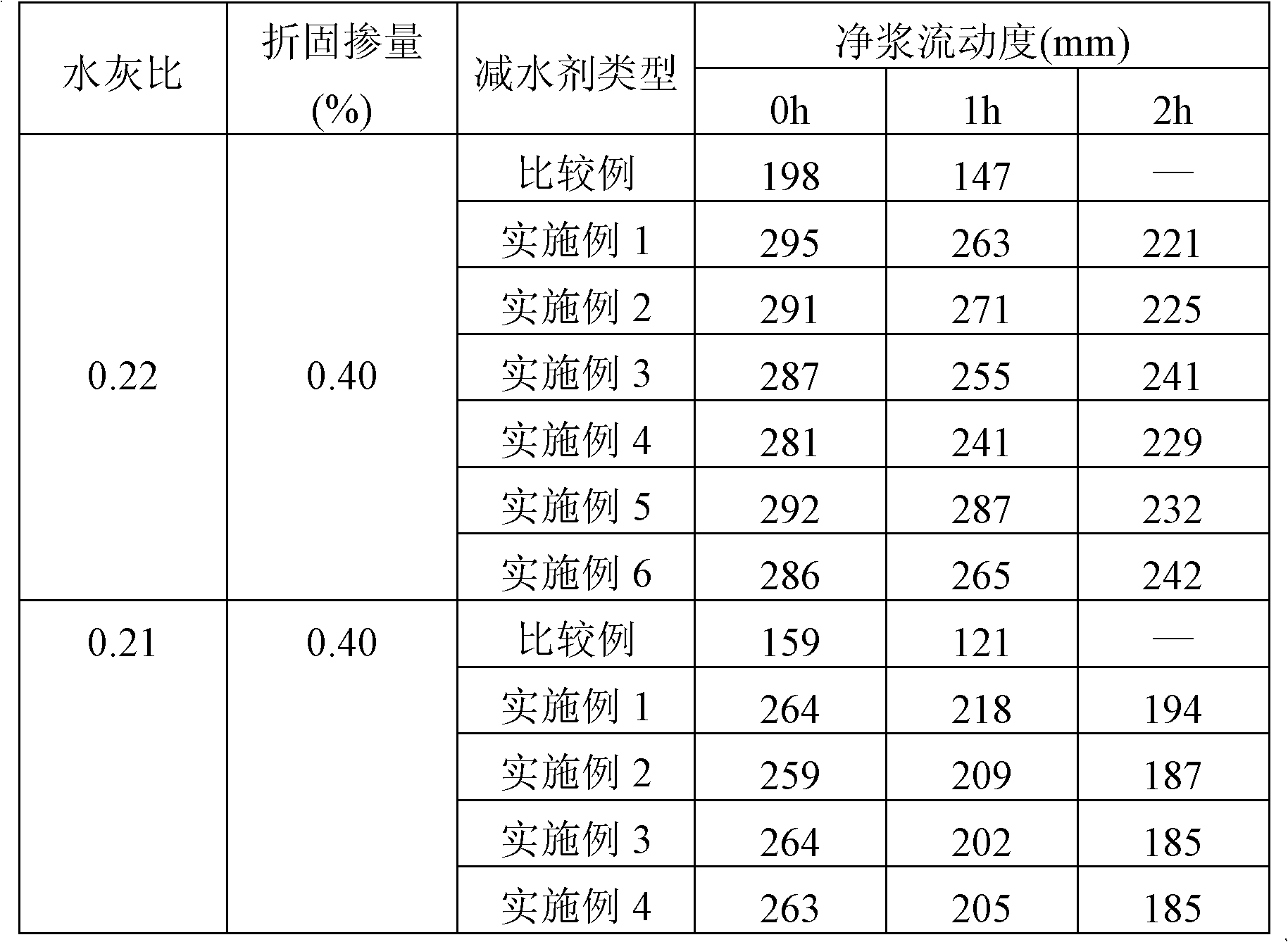

Examples

Embodiment 1

[0020] The aqueous solution of 18.62g polyacrylic acid (concentration 58%) is joined in the reactor, vacuumizes and removes the moisture in the system at 35 ℃, then successively adds 100g amino-terminated polyoxyethylene ethers (molecular weight is 2000) in the reactor, 10g of p-toluenesulfonic acid, add 22.16g of cyclohexane when the temperature rises to 80°C, continue to heat up to 145°C for amidation reaction, separate the water obtained during the reaction, and remove it by vacuuming after 6 hours of reaction Cyclohexane, when the temperature is lowered to 40°C, use 12g of 30% sodium hydroxide solution to neutralize to a pH value of 7, cool to 30°C to obtain the reaction product polyacryloyl polyoxyethylene ether amine, and finally add 281.87g of water Diluted to obtain a concentration of 30% polycarboxylate water reducer.

Embodiment 2

[0022] The polycarboxylate superplasticizer with a concentration of 30% obtained in Example 1 was stored at 5° C. for 20 days, and its implementation effect was measured.

Embodiment 3

[0024] An aqueous solution of 26.33g polymethacrylic acid (concentration 49%) was added in the reactor, and the moisture in the system was removed by vacuuming at 70°C, and then 150g amino-terminated polyoxyethylene ether (molecular weight was 3000 ), 2.3g concentrated sulfuric acid (concentration 98%), add 13.03g toluene when the temperature rises to 100°C, and continue to heat up to 160°C to carry out amidation reaction. Vacuumize to remove toluene, neutralize with 39.2g of 10% potassium hydroxide solution to pH 6 when the temperature is lowered to 60°C, cool to 25°C to obtain the reaction product polyisoacryl polyoxyethylene ether amine, and finally Adding 216.98g of water to dilute to obtain a concentration of 40% polycarboxylate water reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com