Method for producing mineral wool from solid waste by using plasma gasification furnace

A solid waste and gasifier technology, applied in the fields of environmental protection, energy, and building materials production, can solve the problems of complex urban solid waste composition, waste of heat energy, atmospheric heat pollution, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that these specific embodiments are not intended to limit the scope of the invention in any way.

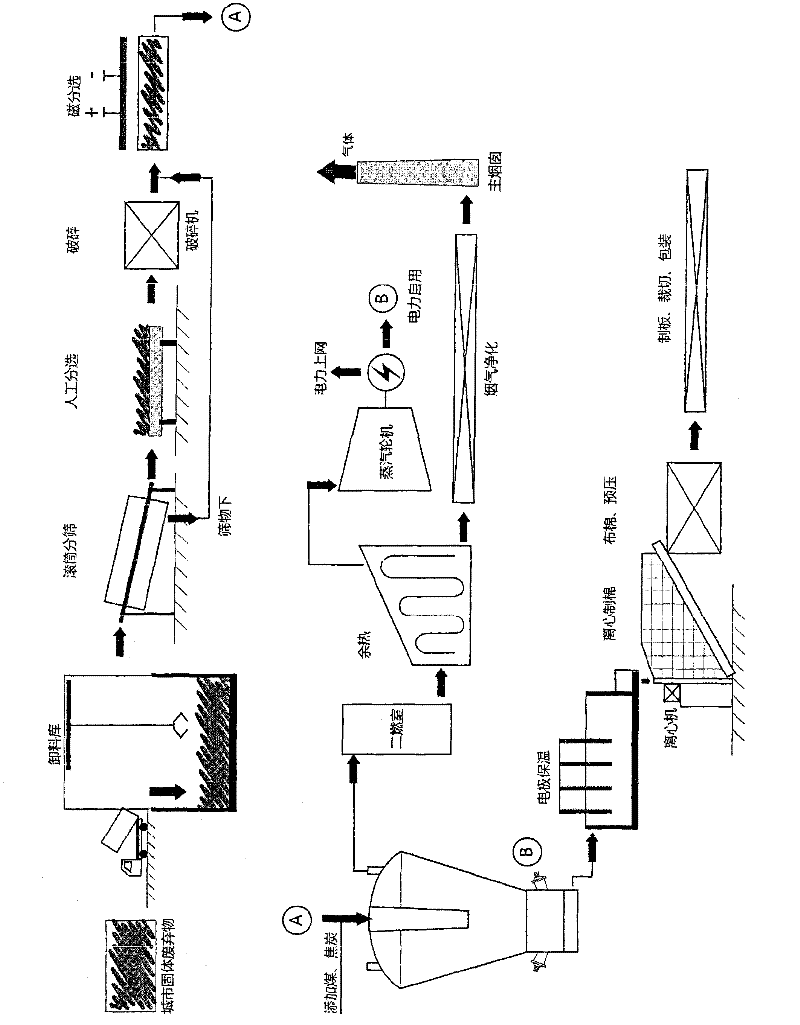

[0024] like figure 1 As shown, the municipal solid waste is sent from the unloading warehouse to the drum sorting device to form bulk materials and small materials. Wherein, the small materials can be directly sent to the magnetic separation device, and the large materials are also sent to the magnetic separation device after manual separation and crushing. Then, the output of the magnetic separation device is preferably fed into a plasma gasifier (purchased from Westinghouse, USA) together with materials such as coal and coke. The gas generated in the upper part of the plasma gasifier is used for power generation and heat supply, etc., and the generated electricity can be used on the grid or for self-use. The glassy hot slag produce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com