Method for purifying lithium hexafluorophosphate and special device thereof

A lithium hexafluorophosphate and purification method technology, which is applied in the field of lithium hexafluorophosphate purification, can solve problems such as increased production costs, corrosion of body tissues, and complicated operations, and achieve the effects of reasonable device structure, corrosion avoidance, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

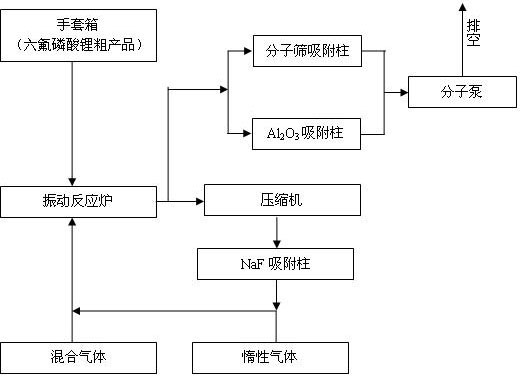

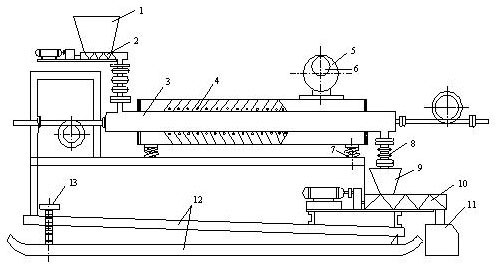

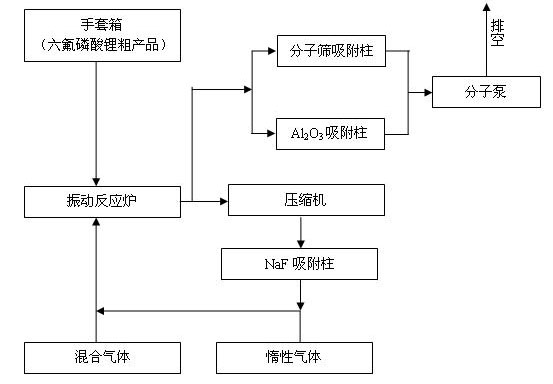

[0035] A method for purifying lithium hexafluorophosphate. First, the vibrating reaction furnace is evacuated and repeatedly cleaned with dry nitrogen, and the Al 2 o 3 Activate the adsorption column and molecular sieve adsorption column, and cool the condenser and molecular sieve adsorption column to -180~-140°C, assemble the gas circulation loop, Al 2 o 3 The adsorption column and the molecular sieve adsorption column are connected to the gas circulation loop, and 0.06MPa dry inert gas is added to the gas circulation loop at the same time; under the protection of dry inert gas in the glove box, the crude product of lithium hexafluorophosphate is added to the hopper of the vibration reaction furnace , this material contains free acid HF600ppm and water 100ppm, start the vibration reaction furnace, inject the mixed gas of dry inert gas and fluorine gas into the gas circulation circuit at the same time, by controlling the rotation frequency of the screw feeder of the vibration...

Embodiment 2

[0044] In the glove box, add 1 kg of crude lithium hexafluorophosphate product to the feeding funnel of the spiral stirring reaction furnace in advance. This material contains 620 ppm of free acid HF and 130 ppm of water. Vacuumize the gas circulation loop, then feed 0.06MPa high-purity argon into the gas circulation loop, and repeat the above process 3 times. Cool the molecular sieve adsorption column to -180 to -140°C, and then start the compressor to circulate the gas in the gas circulation loop. Start the screw feeder of the vibration reaction furnace, push the crude product of lithium hexafluorophosphate onto the tray of the vibration reaction furnace, and at the same time slowly feed the mixed gas of fluorine gas and argon gas into the gas circulation loop until the pressure in the gas circulation loop is 0.1MPa, stop feeding the mixed gas of fluorine gas and argon gas into the gas circulation loop, and keep the gas circulation for 3 hours, then stop the gas circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com