Method for detecting broken chains of swaying rack chain fall

A detection device and chain technology, used in conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of normal production operation, limited downtime, damage, etc., to shorten the maintenance time and reduce production costs. , Improve the effect of maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

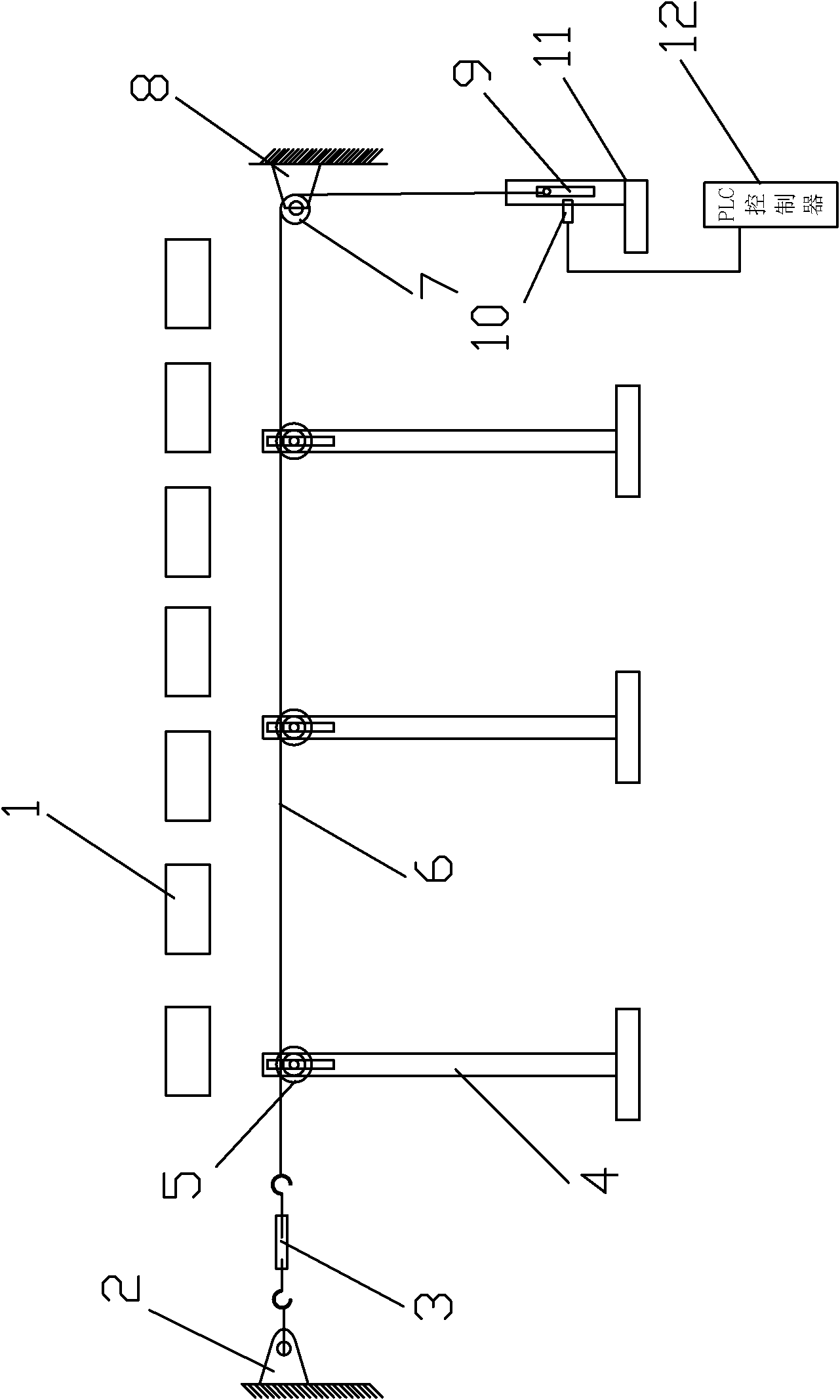

[0015] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, several side-by-side chains 1 are arranged on the traversing platform, the chains 1 are connected to the driving motor (not shown in the figure), the driving motor is connected to the PLC controller 12, and the PLC controller 12 can control the forward and reverse rotation of the driving motor. Thereby realize the back and forth movement of chain 1. When the traversing stand is in use, the plate is placed on the chain 1, so that under the drive of the driving motor, the chain can realize the conveying of the plate.

[0017] The chain break detection device of the traversing gantry includes a steel wire rope 6, one end of the steel wire rope 6 is connected with a fixed bracket 2 through a turnbuckle 3, the fixed bracket 2 is fixed on the wall, and the turnbuckle 3 can be used to adjust the tension of the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com