Bisphenol-A-free heat-sensitive paper

A thermal paper and bisphenol technology, which is applied in the production process of thermal paper, can solve the problems of high melting point of oxidizing agent, inability to adapt to technical difficulties, and inability to widely cancel bisphenol A.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

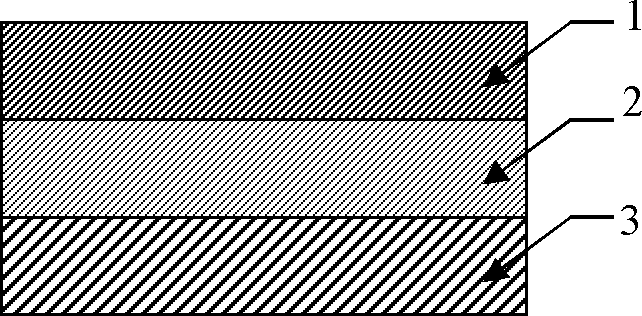

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail, as shown in the figure: 1 is the chromogenic layer, 2 is the precoat layer, and 3 is the base paper layer.

[0019] The thermal paper includes a base paper layer, a precoat layer and a color-developing layer coated once on the base paper layer.

[0020] The formulation and production method of the pre-coating layer: 100 parts of filler and 5-35 parts of adhesive are mixed under high-speed stirring to form a coating solution with a solid content of 30-40%. Apply on the base paper layer with a coater, the coating amount is 5~15g / m 2 . The filler is a single product or a mixture of light calcium carbonate, silicon dioxide, calcined kaolin, flaked clay, and hollow plastic pigment. The adhesive is a single emulsion or a mixture of styrene-butadiene latex, styrene acrylic resin, starch, polyvinyl alcohol, and acrylic resin.

[0021] The chromogenic layer is made of the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com