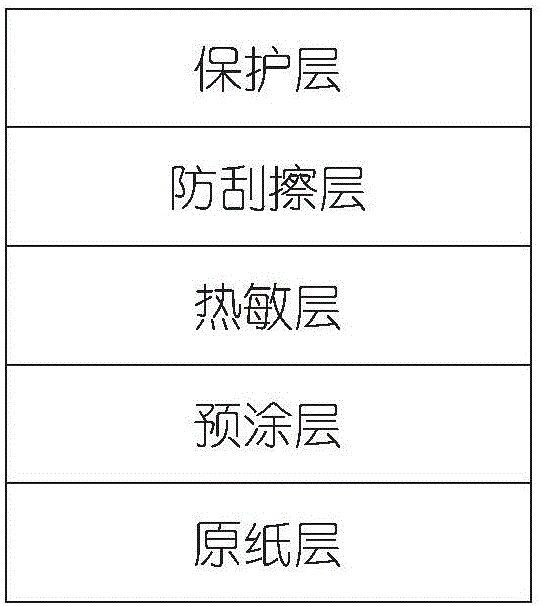

Anti-scraping thermo-sensitive paper and manufacturing method thereof

A manufacturing method and heat-sensitive paper technology, which is applied in the field of papermaking, can solve the problems of poor scratch resistance of paper, affecting normal logistics distribution, unrecognizable graphic and barcode information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of scratch-resistant thermal paper, its manufacturing steps are as follows:

[0042] (1) The composition and preparation method of the pre-coat:

[0043] 100 parts of light calcium carbonate and 20 parts of styrene-butadiene latex are mixed under high-speed stirring to form a coating solution with a solid content of 30%; use a coating machine to coat the base paper layer, and the coating amount is 9g / m 2 ;

[0044] (2) Preparation components and production methods of the chromogenic layer:

[0045] Component A: 40 parts of oxidant bisphenol A, 3 parts of polyvinyl alcohol, mixed to prepare a mixed solution with a concentration of 40%, and ground to a mixed solution of 0.3 to 1.5 microns in a wet grinder;

[0046] Component B: 40 parts of sensitizer 1, 2-diphenoxyethane, 3 parts of polyvinyl alcohol, mixed to prepare a mixed solution with a concentration of 35%, and ground to a mixed solution of 0.2-1.7 microns in a wet grinder;

[0047] Component C: 40 parts o...

Embodiment 2

[0053] A method for manufacturing scratch-resistant thermal paper, the steps are as follows:

[0054] (1) The composition and preparation method of the pre-coat:

[0055] A filler silica, 100 parts of calcined kaolin, and A adhesive styrene acrylic resin 25 parts are mixed under high-speed stirring to form a coating solution with a solid content of 40%; use a coater to coat the base paper layer, and the coating amount 9g / m 2 ;

[0056] (2) Preparation components and production methods of the chromogenic layer:

[0057]Component A: 40 parts of oxidizing agent 4,4'-dihydroxydiphenyl sulfone, 4 parts of polyvinyl alcohol, mixed to prepare a mixed solution with a concentration of 50%, and ground to a mixed solution of 0.3-1.5 microns in a wet grinder;

[0058] Component B: 40 parts of sensitizer diphenyl sulfone and 4 parts of polyvinyl alcohol are mixed to prepare a mixed solution with a concentration of 45%, and ground to a mixed solution of 0.2 to 1.7 microns in a wet grinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com