Swinging joint of small-sized electric manipulator

A technology of electric manipulators and joints, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of affecting motor efficiency, complex joint structure, unfavorable miniaturization, etc., to achieve modularization, great flexibility, and miniaturization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

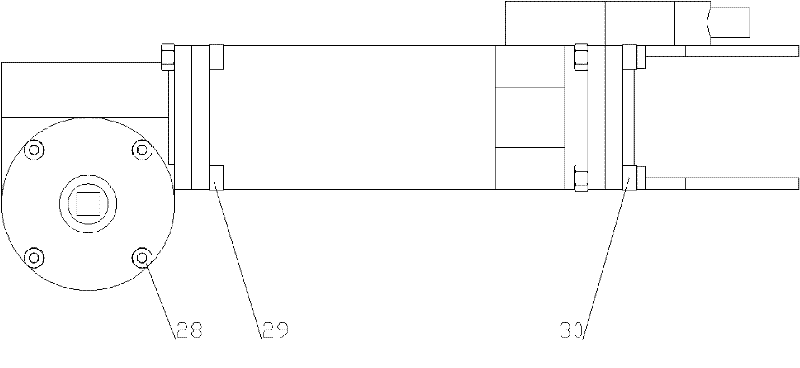

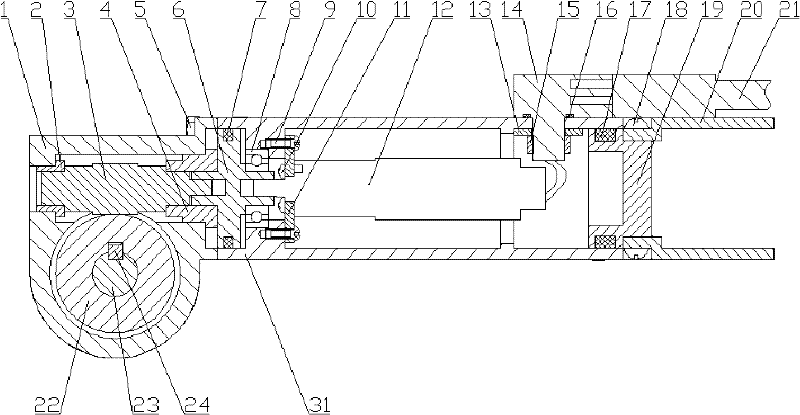

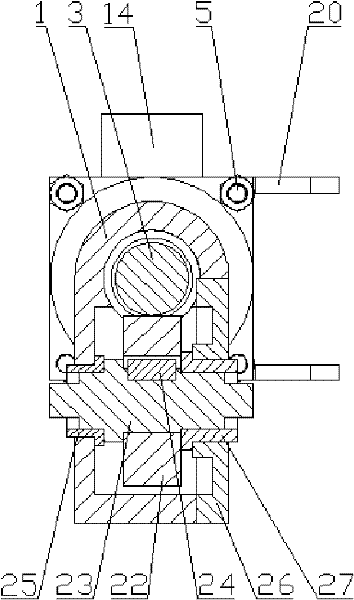

[0020] combine figure 1 , figure 2 , the main composition of the present invention includes main parts such as swing mechanism, mechanical arm and swing connection, and mechanical arm is the main body of the present invention, comprises mechanical arm shell 31, drive motor 12, motor connecting plate 11, angular contact bearing 8, coupling 6. Main parts such as gray ring 7, watertight cable socket 14, etc., the swing mechanism includes swing mechanism shell 1, swing mechanism cover 26, worm 3, worm wheel 22, worm wheel shaft 23, and sliding bearings of the worm screw and worm wheel shaft, etc., swing The connection part includes a manipulator cover 19 and a swing connection plate 20 .

[0021] Wherein the drive motor 12 is installed on the motor connecting plate 11 by the motor connecting screw 10, and then it is installed in the manipulator shell 31 by the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com