Effervescent atomization medicament applying spray head

A nozzle and air bubble technology, which is applied in the direction of spraying devices, liquid spraying devices, devices for catching or killing insects, etc., can solve the problems of poor droplet penetration, large energy consumption, and large atomization air consumption, etc., to achieve fog Good melting effect, improved adaptability, and fine droplet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

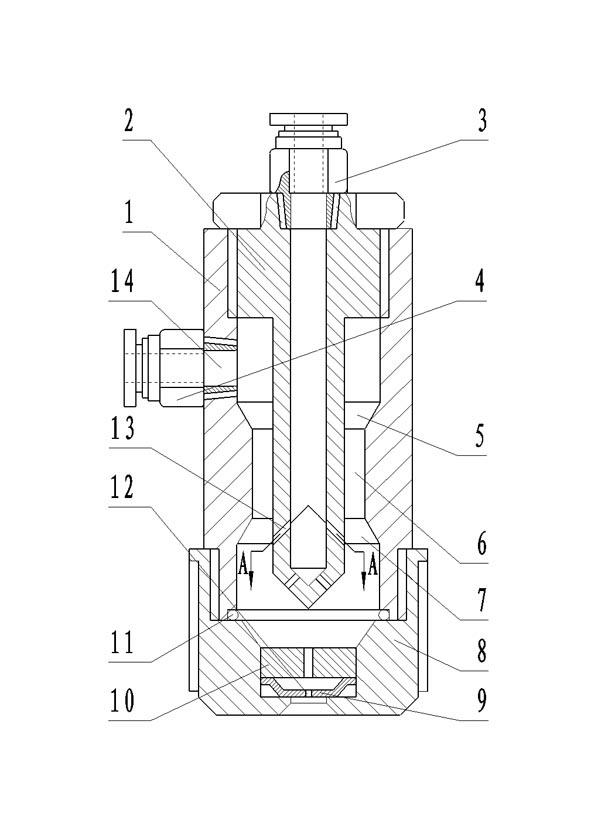

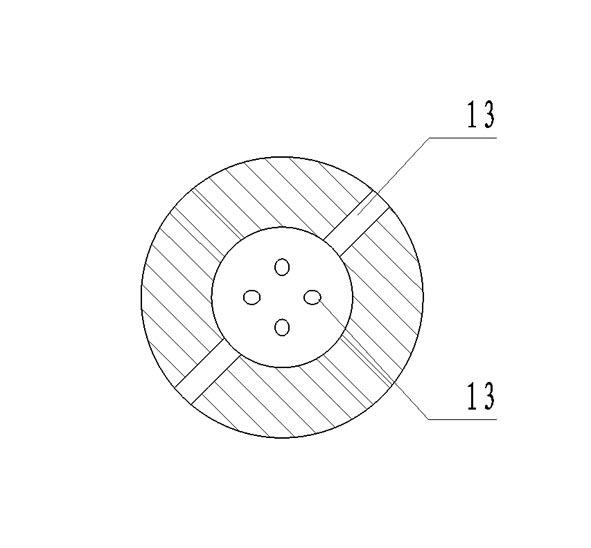

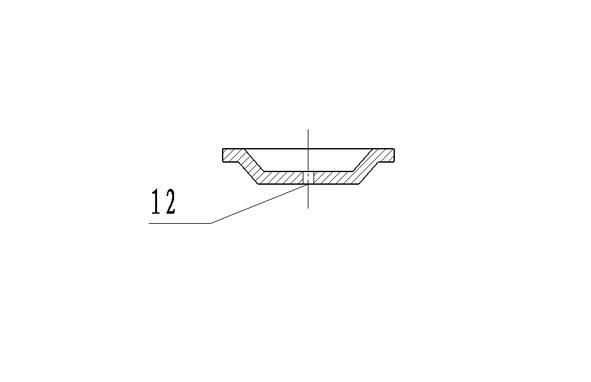

[0019] This embodiment includes a nozzle body 1, a spray sheet 9, pipe joints 3, 4, and a nozzle cap 8. The nozzle body is provided with a nozzle body cavity, and the nozzle body cavity is provided with a shrinkage cavity 8, a throat cavity 6, and an expansion cavity 7. , the nozzle body shrinkage cavity is a platform with a large upper part and a smaller lower part, the nozzle body throat cavity is cylindrical, located below the contraction cavity, the diameter of the cylinder is the same as the diameter of the small end of the contraction cavity, and the nozzle body expansion cavity It is a table shape with a small upper part and a larger lower part. The diameter of the small end is the same as that of the throat cavity. The tail end of the generator is provided with air injection holes 13 arranged in a staggered space, and the air inlet pipe joint 3 for the bubble generator is connected with the nozzle body 1. There is a liquid inlet hole on the side of the nozzle body, and ...

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is that the included angle between the central line of the air injection hole on the bubble generator and the axis of the bubble generator of the nozzle body is 50°.

Embodiment 3

[0025] The difference between this embodiment and Embodiment 1 is that the included angle between the central line of the gas injection hole on the bubble generator and the axis of the bubble generator of the nozzle body is 45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com