Micro-pressure cooker

A technology for pots and pot lids, which is applied to household utensils, kitchen utensils, lids of cooking utensils, etc., can solve the problems of delaying the cooking time, not considering the negative pressure of opening the lid and the positive pressure of closing the lid, etc., so as to reduce the consumption of energy. , the effect of precise temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

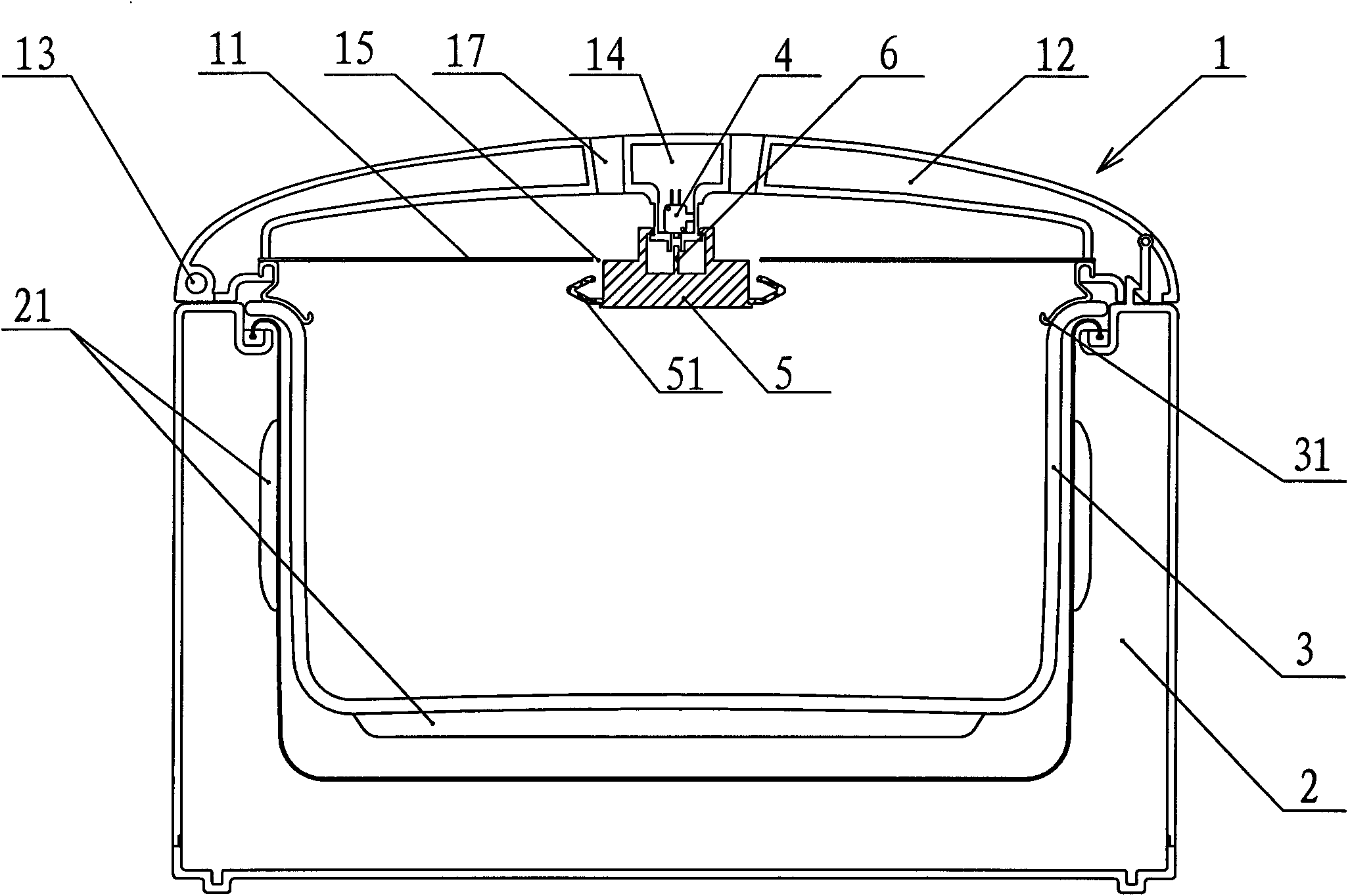

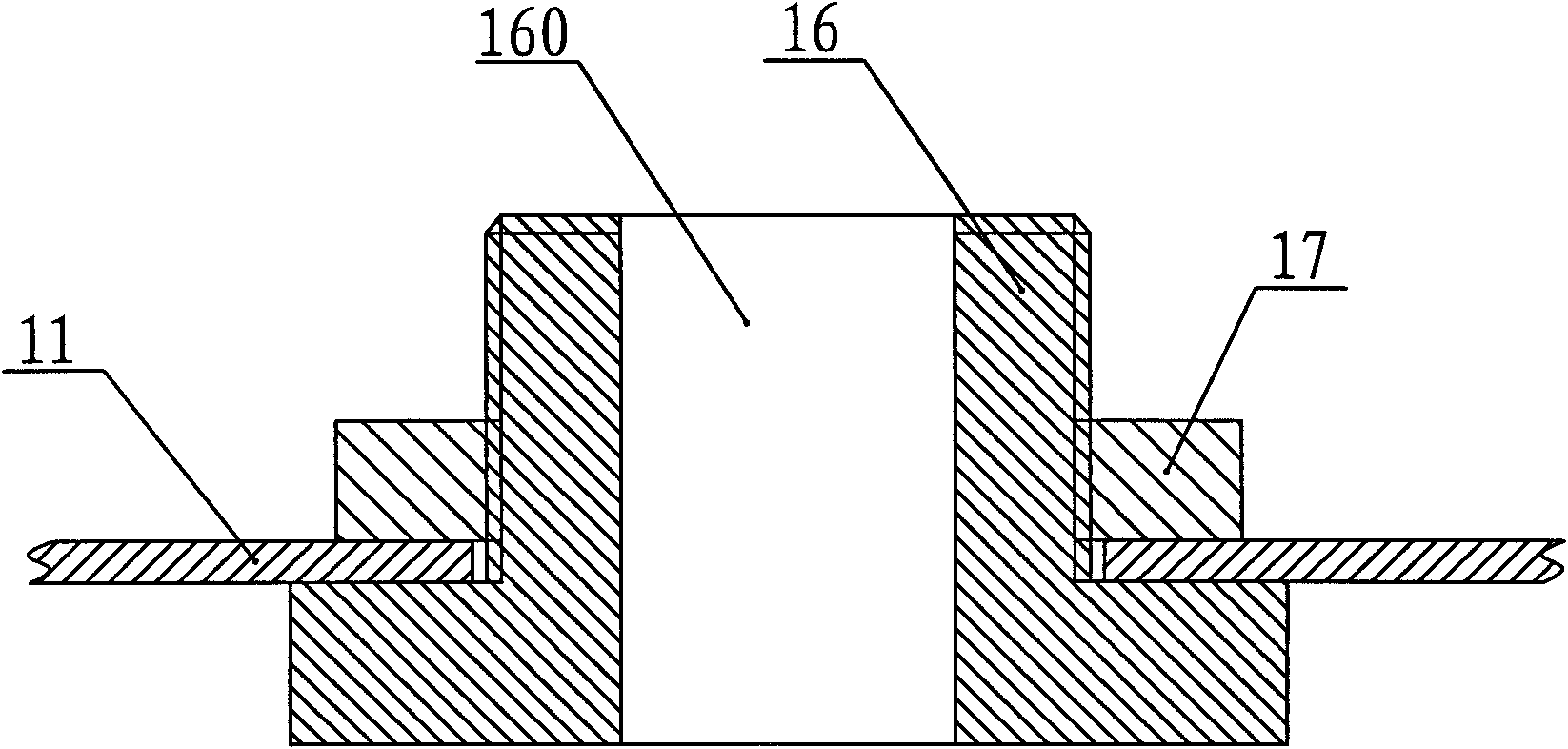

[0038] Such as figure 1 As shown, a micro-pressure cooker includes a pot cover 1, a pot body 2, an inner pot 3 and a heater 21, wherein the pot body 2 is the main bearing part of the micro-pressure cooker, and an inner pot is arranged inside 2. The heater 21 and the electric control system of the micro-pressure cooker, the pot cover 1 is located on the top of the pot body 2 and is provided with an inner pot sealing ring 31 between the inner pot 2, The pot cover 1 is provided with a signal switch 4 .

[0039] The pot cover 1 includes an outer shell 12 and an inner cover 11 , and the pot cover 1 is hingedly connected by a hinge device 13 provided between the outer shell 12 and the pot body 2 so that it can be flipped. The inner pot 3 is arranged in the pot body 2, and the outer periphery (side or / and bottom) of the inner pot 3 is provided with a heater 21, and the heater 21 can be attached to the inner pot 3. The outer surface can also be pasted on the outer surface of the out...

Embodiment 2

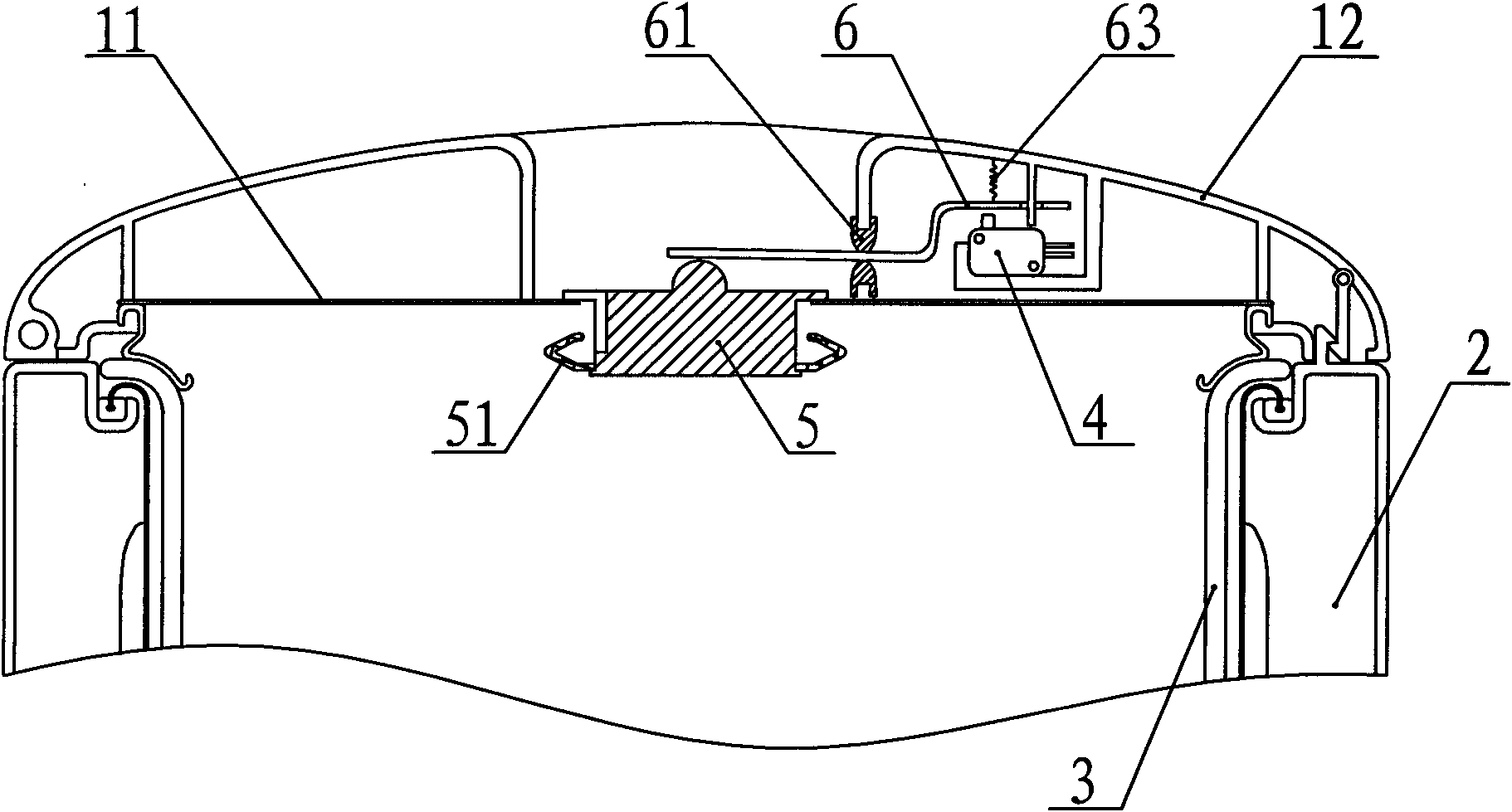

[0046] Such as image 3 As shown, the difference from Embodiment 1 is that the first air release valve core 5 is T-shaped and hangs in the first cover hole 15, and the signal switch 4 is not located on the first air release valve core 5. But the above is offset by a certain distance, the transmission arm 6 is arranged laterally and a fulcrum 61 is set at the middle position of the transmission arm 6, and a sealing device is set between the fulcrum 61 and the transmission arm 6, so that the pot can The exhausted steam will not enter the area where the signal switch 4 is located, which protects the safety of the signal switch 4 in use. Next, return spring 63 is set on the right side of described fulcrum 61, and one end of described return spring 63 is fixedly connected on the described pot cover 1, and the other end is connected with described transmission arm 6, thereby described return spring 63 can not only increase The rotational force of transmission arm 6, and described t...

Embodiment 3

[0048] Such as Figure 4 As shown, the difference from the second embodiment is that the signal switch 4 is arranged on the upper part of the pot body 2, and a water-proof cover 7 is arranged between the signal switch 4 and the transmission arm 6; Figure 5 As shown, the water avoiding cover 7 is in the shape of a mountain, wherein the two side arms 72 of the water avoiding cover 7 are provided with barbs 73 and are snapped on the outer wall of the pot body 2 in a movable up and down manner. The middle arm body 71 of water avoiding cover 7 pushes on the button of described signal switch 4; The upright wall 22 adapted to the annular wall 73 , the upright wall 22 is inserted into the annular wall 73 . In this way, the water-proof cover 7 can slide on the vertical wall 22 but will not come out, and external pollutants will not enter the pot body 2; secondly, the signal line of the signal switch 4 can not be connected. onto the lid 1. In addition, a reset spring (not shown) can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com