Device and process for removing red skin of peanuts by partitioned temperature control quick cooling at low temperature

A technology of segmented temperature control and cooling device, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of shortening the shelf life of peanuts, surface damage of peanuts, and deterioration of peanut oil quality, etc., and achieves a high degree of equipment automation. Reasonable structure setting and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

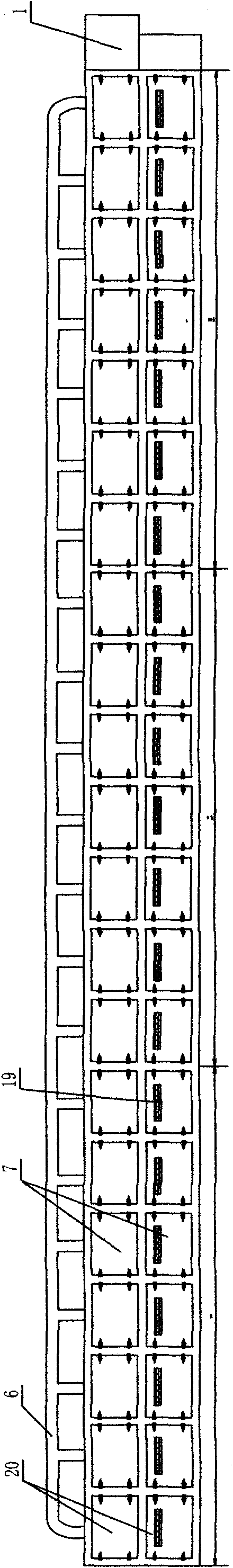

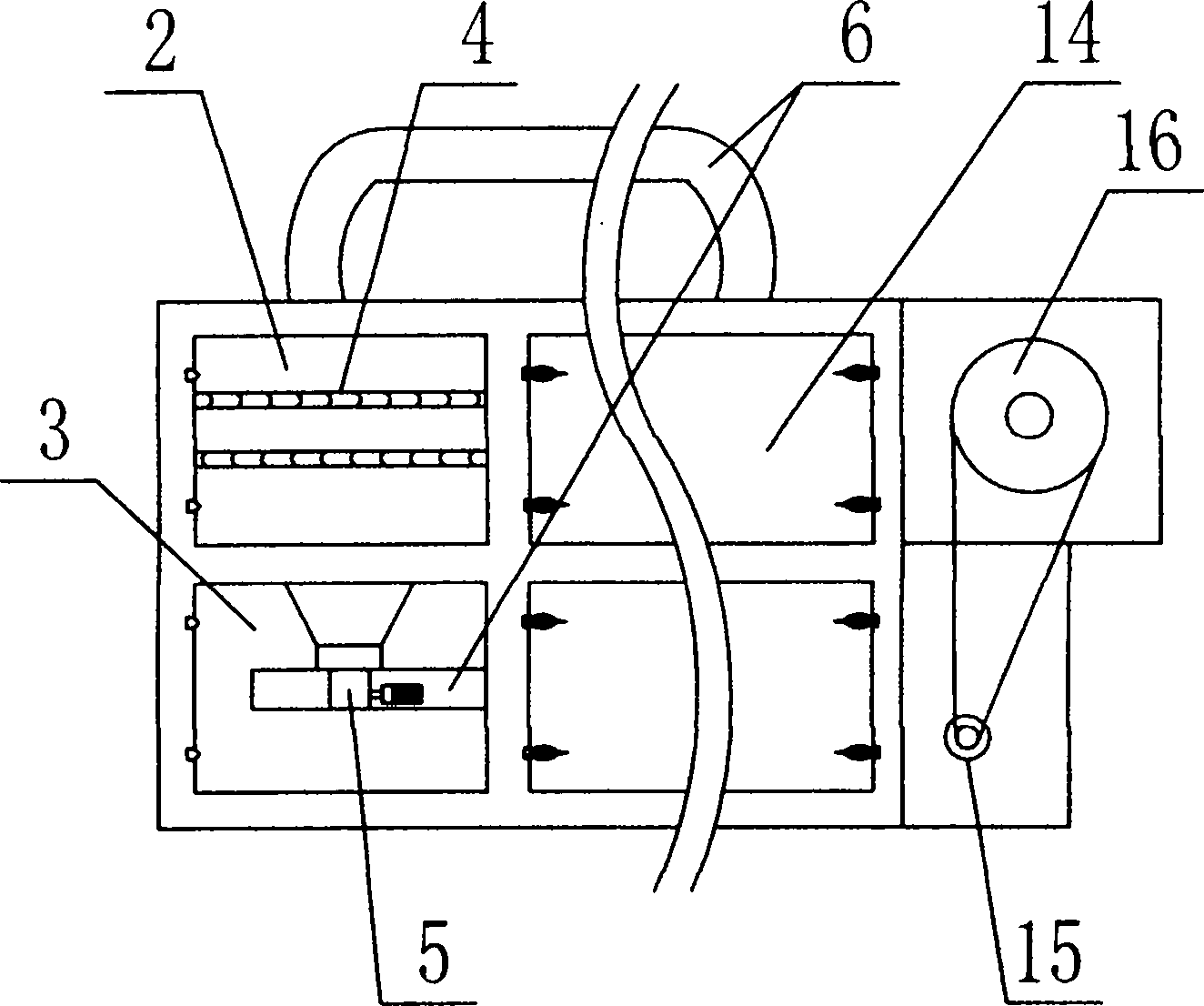

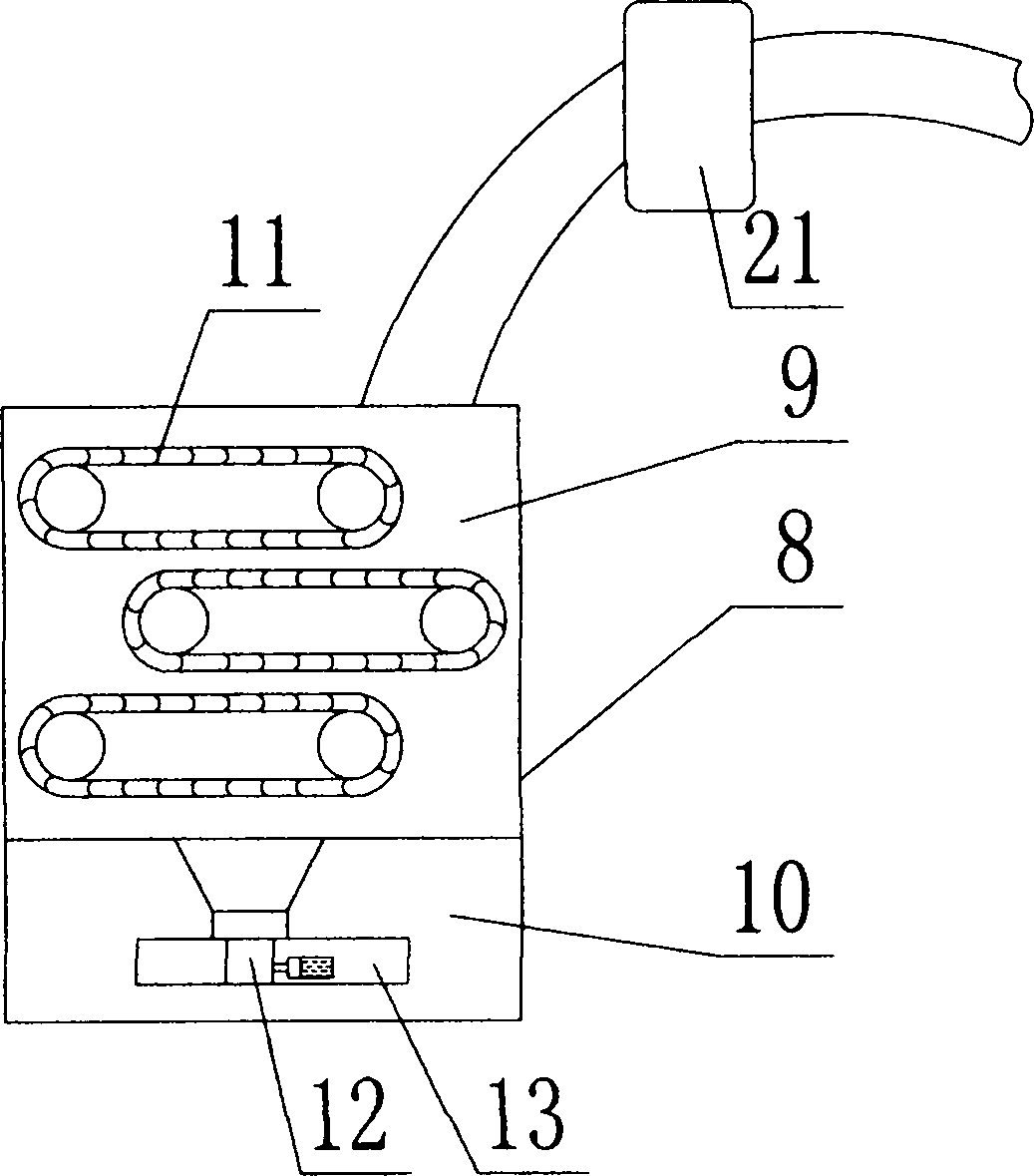

[0017] A low-temperature segmented temperature-controlled quick-cooling device for peanuts, including a roasting device and a cooling device connected to it. The roasting device is connected to a heat source, and the cooling device is connected to a cold source. The roasting device includes Power box 1 and three groups of ovens 7 connected together, each group of ovens 7 is provided with a humidification box 20 before, the humidity is maintained in the humidification box 20 and humidity sensor, peanut conveyor belt 4 is arranged; the oven 7 is divided into an upper box 2 and the lower box 3, the upper box 2 is provided with a peanut conveyor belt 4, the conveyor belt 4 is connected with the power transmission device in the power box 1, the lower box 3 is provided with a heat source fan 5, and the heat source fan 5 is connected to the heat source through the pipeline 6 And the upper box 2 is connected, the upper box 2 is connected with the heat source through the pipeline 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com