Coconut-water beverage and preparation method thereof

A coconut water and beverage technology, applied in the field of beverages, can solve problems such as loss of delicious taste, influence on nutritional and health care value, destruction of physiological activity, etc., and achieve the effect of convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

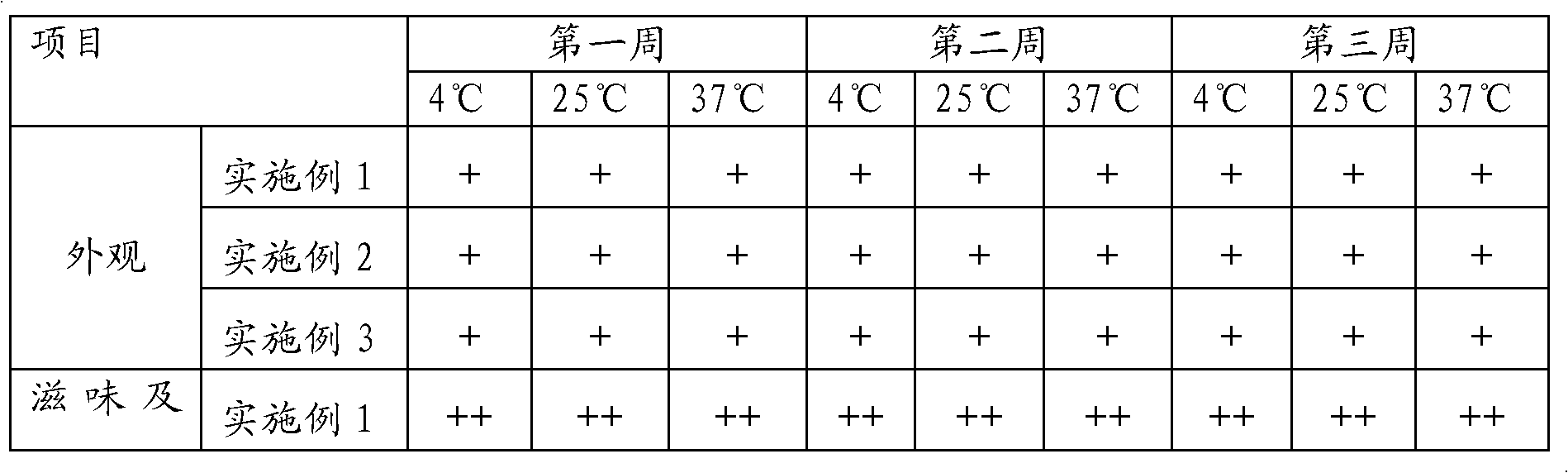

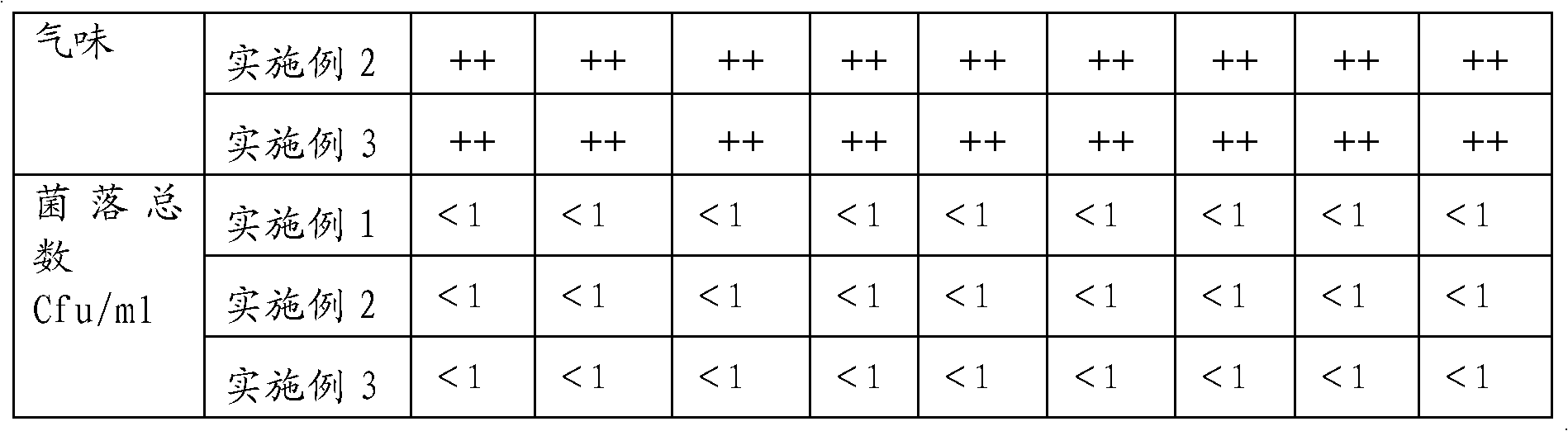

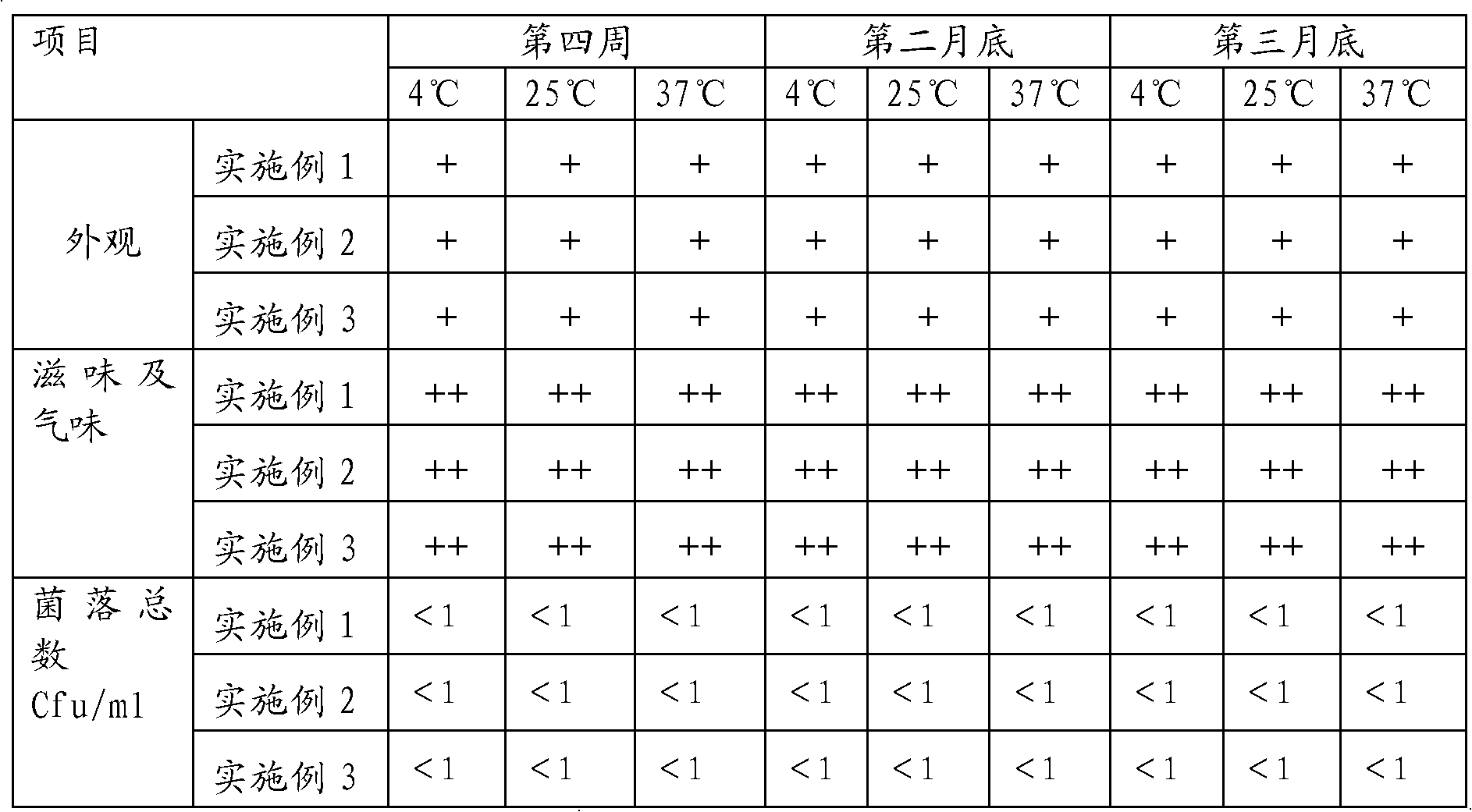

Embodiment 1

[0038] Peel off the non-deteriorated coconut shell and get 100kg of water, quickly add 100g of ascorbic acid and stir to dissolve, remove impurities by centrifugal filtration with a 16000rpm (rev / min) centrifuge, add 25kg of pure water, dissolve sucrose with hot water, the concentration is 60%, stir and add sucrose liquid adjustment to 7.0 0 Brix, stir and add citric acid to adjust the pH to 4.6. The prepared coconut water is sterilized by filtration through a membrane with a pore size of 0.02 μm, and then sterilized by 400MPa ultra-high pressure and low temperature (25°C) for a second sterilization treatment for 15 minutes. The sterilized aluminum pop cans are aseptically filled into finished coconut water beverages, with a net capacity of 245ml. If necessary, it can also be packed into airtight containers with other capacities.

Embodiment 2

[0040] Peel off the non-deteriorated coconut shell and get 200kg of water, quickly add 150g of ascorbic acid and stir to dissolve, remove impurities by centrifugal filtration with a 20000rpm (rev / min) centrifuge, add 50kg of pure water, dissolve sucrose with hot water, the concentration is 60%, add sucrose with stirring liquid adjustment to 8.0 0 Brix, stir and add citric acid to adjust to pH 4.7, the prepared coconut water is sterilized by filtering through a membrane with a pore size of 0.02μm, and under sterile conditions, add 7.5kg of high-temperature sterilized coconut fiber fruit and stir evenly, and then use 600MPa Ultra-high pressure and low temperature (20°C) sterilization for the second time for 10 minutes, and aseptically filling in high-temperature sterilized aluminum pop-top cans into the finished product of coconut water beverage with a net capacity of 245ml. If necessary, it can also be packed into airtight containers with other capacities.

Embodiment 3

[0042] Peel off the non-deteriorated coconut shell and get 500kg of water, quickly add 600g of ascorbic acid and stir to dissolve, remove impurities by centrifugal filtration with a 18000rpm (rev / min) centrifuge, add 125kg of pure water, dissolve sucrose with hot water, the concentration is 60%, stir and add sucrose liquid adjustment to 8.0 0 Brix, stir and add citric acid to adjust to pH 4.8, the prepared coconut water is sterilized by filtration through a membrane with a pore size of 0.2 μm, and 31 kg of high-temperature sterilized coconut meat is added under sterile conditions and stirred evenly, and then 500MPa ultra- High-pressure low-temperature (28 ℃) sterilization is sterilized for the second time for 12 minutes, and the coconut meat coconut water beverage finished product is made into coconut meat coconut water beverage with aseptically filling through high-temperature sterilized aluminum pop-top cans, and its net capacity is 245ml. If necessary, it can also be packed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com