Microporous foaming polypropylene fiber and preparation method thereof

A foamed polypropylene and microporous technology, applied in fiber processing, single-component polyolefin artificial filament, filament/thread forming, etc., can solve the problems of low production efficiency, harsh preparation conditions, etc., and achieve production cost Low cost, good economic and social benefits, and excellent operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

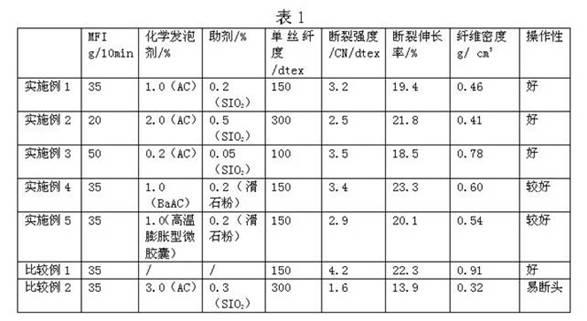

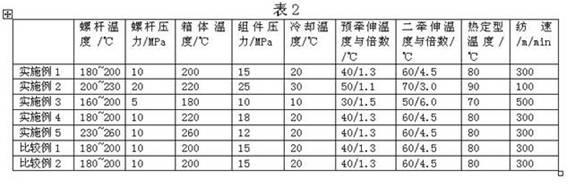

Embodiment 1

[0019] In this embodiment, polypropylene resin with an MFI of 35g / 10min is used as a raw material, and AC chemical foaming agent accounting for 1.0% by weight of the raw material, silicon dioxide accounting for 0.2% by weight of the raw material, and 1% red color masterbatch are added. , fed into the screw extruder according to the set ratio, the temperature of each area of the screw is 180-200°C, and the pressure is 10Mpa, melted and mixed through the screw extruder, so that the chemical foaming agent is in a critical state about to be decomposed, measured by The pump is metered stably, and it is continuously fed into the spinning assembly with a temperature of 200°C and an assembly pressure of 15Mpa, and it is sprayed out from the spinneret hole; during the rapid pressure drop, the chemical foaming agent decomposes and gasifies, forming a microporous extrusion The microporous extruded material enters a cooling water tank with a temperature of 20°C after passing through an a...

Embodiment 2

[0021] In this embodiment, polypropylene resin with an MFI of 20g / 10min is used as a raw material, and AC chemical blowing agent accounting for 2.0% by weight of the raw material, silicon dioxide accounting for 0.5% by weight of the raw material, and 2% yellow masterbatch are added. , fed into the screw extruder according to the set ratio, the temperature of each area of the screw is 200-230°C, and the pressure is 25Mpa, melted and mixed through the screw extruder, so that the chemical foaming agent is in a critical state about to decompose, measured by The pump is metered stably, and it is continuously fed into the spinning assembly with a temperature of 220°C and an assembly pressure of 15Mpa, and it is sprayed out from the spinneret hole; during the rapid pressure drop, the chemical foaming agent decomposes and gasifies, forming a microporous extrusion The microporous extruded material enters a cooling water tank with a temperature of 30°C after passing through an air laye...

Embodiment 3

[0023] This embodiment adopts the polypropylene resin that MFI is 50g / 10min as raw material, adds the AC chemical foaming agent that accounts for 0.2% by weight percentage of raw material, accounts for 0.05% talcum powder that accounts for raw material weight percentage, 3% green color masterbatch, according to The set ratio is fed into the screw extruder. The temperature of each area of the screw is 160-200°C and the pressure is 5Mpa. Through the screw extruder, it is melted and mixed to make the chemical foaming agent in a critical state about to be decomposed, and stabilized by the metering pump. Metering, continuously feeding into the spinning assembly with a temperature of 180°C and a component pressure of 10Mpa, and spraying it out from the spinneret hole; during the rapid pressure drop process, the chemical foaming agent decomposes and gasifies to form a microporous extrudate. The microporous extruded material passes through an air layer and then enters a cooling water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com