Beneficiation method for high armangite

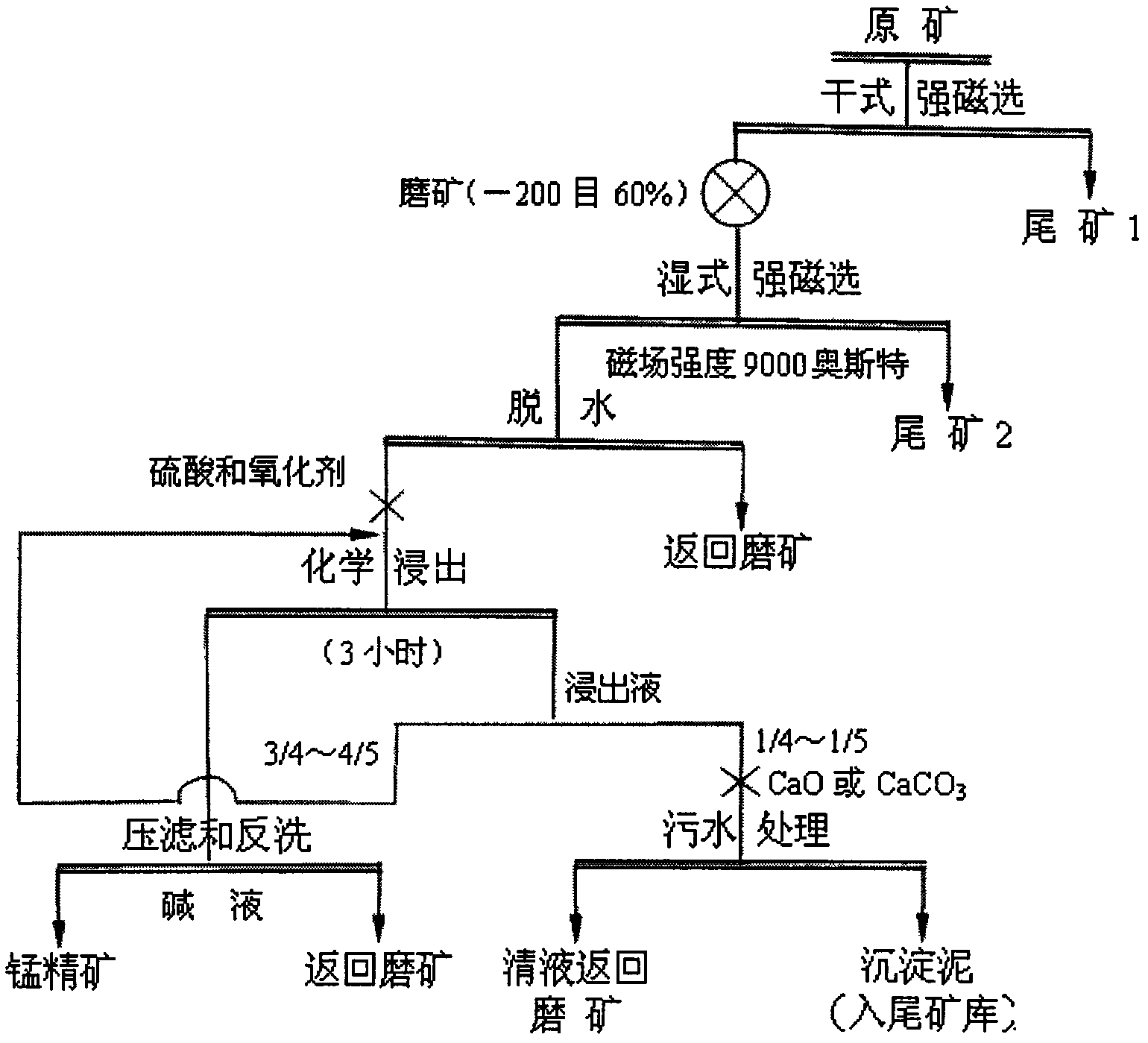

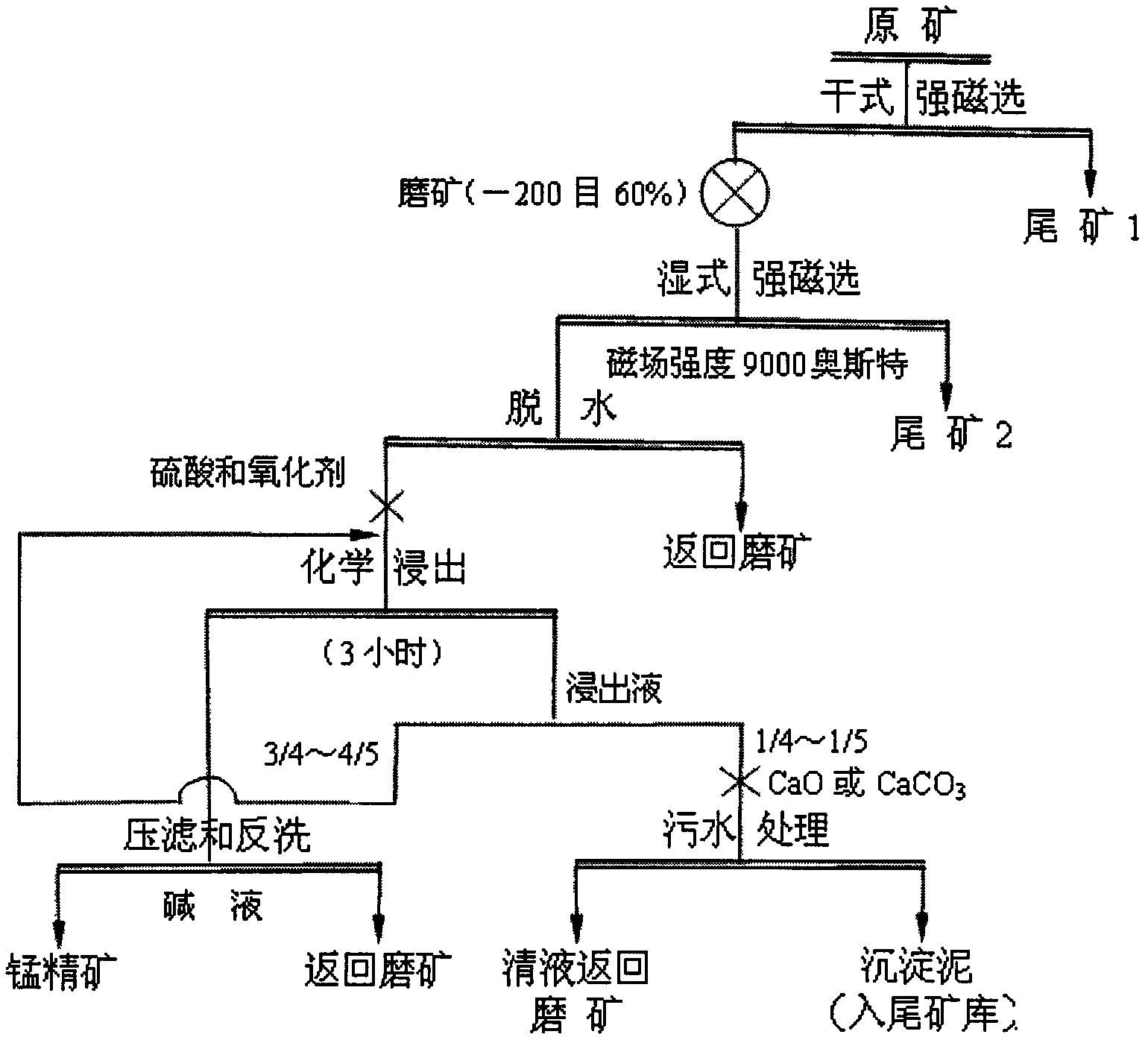

A technology for high arsenic manganese ore and manganese ore, which is applied in chemical instruments and methods, wet separation, improvement of process efficiency, etc., can solve the problems that affect the development and utilization of manganese ore resources, and no published documents on beneficiation of high arsenic manganese ore have been found. The effect of good economic benefits, saving production water and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The Algerian high-arsenic manganese ore containing 37.09% by weight of manganese and 4.92% by weight of arsenic is subjected to dry strong magnetic separation under the technological conditions of a magnetic field strength of 13,000 Oersted, and the raw manganese ore selected is then ground into After the particle size of 60% is -0.074mm, under the technological condition that the magnetic field strength is 9000 Oersted, carry out wet strong magnetic separation, and then use the sulfuric acid with the concentration of 98% of the ore in an amount of 360Kg / t and the H of the ore in an amount of 1Kg / t 2 o 2 , carry out the wet chemical leaching reaction, the reaction time is 3 hours, the leachate in the upper layer of the reaction liquid precipitation is reused, the manganese slag is treated with calcium salt to achieve discharge, the reaction liquid precipitate is neutralized with lime milk solution, and the pH value is controlled at 7 to obtain manganese Concentrate prod...

Embodiment 2

[0031] The high-arsenic manganese ore containing 36.27% by weight of manganese and 5.03% by weight of arsenic is subjected to dry strong magnetic separation under the technological conditions of a magnetic field strength of 12000 Oersted. After the particle size of % is -0.074mm, under the process condition that the magnetic field intensity is 8500 Oersted, carry out wet strong magnetic separation, and then use the sulfuric acid with the concentration of 98% of the ore in the amount of 355Kg / t and the concentration of the ore in the amount of 0.9Kg / t h 2 o 2 , carry out the wet chemical leaching reaction, the reaction time is 2.5 hours, the leaching solution of the upper layer of the reaction liquid precipitation is reused, the manganese slag is treated with calcium salt to achieve discharge, and the reaction liquid precipitate is neutralized with lime milk solution, and the pH value is controlled at 6.6 to obtain manganese Concentrate products.

[0032] In this example, a m...

Embodiment 3

[0034] The Algerian high-arsenic manganese ore containing 38.15% by weight of manganese and 5.11% by weight of arsenic is subjected to dry strong magnetic separation under the technological conditions of a magnetic field strength of 13600 Oersted, and the raw manganese ore selected is then ground into After 60% of the particle size is -0.074mm, use a magnetic field strength of 9500 Oersted to carry out wet strong magnetic separation, and then use 365Kg / t of sulfuric acid with an ore concentration of 98% and 1.1Kg / t of ore H 2 o 2 , carry out the wet chemical leaching reaction, the reaction time is 3.5 hours, the leaching solution of the upper layer of the reaction liquid precipitation is reused, the manganese slag is treated with calcium salt to achieve discharge, and the reaction liquid precipitate is neutralized with lime milk solution, and the pH value is controlled at 7.6 to obtain manganese Concentrate products.

[0035] In this example, a manganese concentrate product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com