Asphalt cold recycling agent and preparation method thereof

A cold regenerant and asphalt technology, applied in building components, sustainable waste treatment, solid waste management, etc., can solve the problem that the quality of asphalt mixture cannot meet the asphalt quality standard, the old asphalt material is not fully utilized, and it can only be used in the base layer. and other problems, to avoid landslides and vegetation reduction, improve regeneration utilization rate, and reduce mining effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

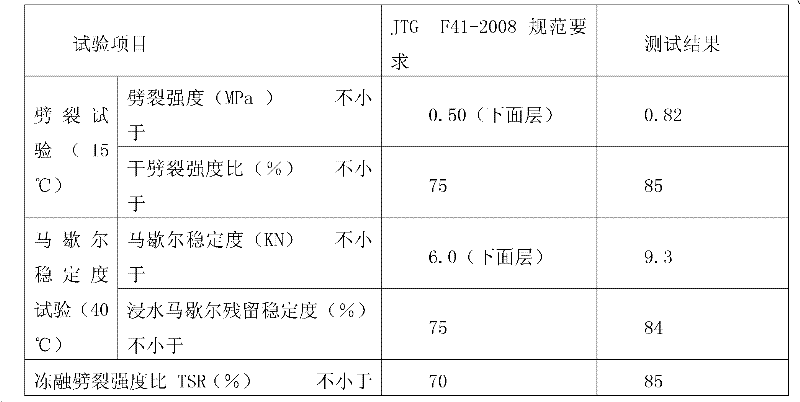

Embodiment 1

[0026] 280g of aromatic oil, 7.5g of 4010NA and 7.5g of antioxidant 1010, 15g of 2,4-dimethylol benzophenone, and 350g of epoxy resin E51 are stirred evenly without particles, which is asphalt pavement cold regeneration agent A. Mix 300g cashew nut oil modified amine and 40g ZY-10 glycidyl ester evenly to obtain asphalt pavement cold regenerant B, and mix asphalt pavement cold regenerant A and cold regenerant B according to the ratio of the above-mentioned weight ratio of 66:34 to obtain asphalt pavement cold regenerant Regenerant. Heat the waste asphalt concrete dug or milled on site (the old milling material of Chongqing Yufu Expressway, which has been used for 6 years) to 60°C, gently grind it with a wooden stick, sieve it, and cool it to room temperature. Engineering asphalt and asphalt mixture test procedures JTJ 052-2000 "Abson method to recycle aged asphalt, in the recovered aged asphalt, add the asphalt cold regeneration agent prepared above according to the weight rat...

Embodiment 2~6

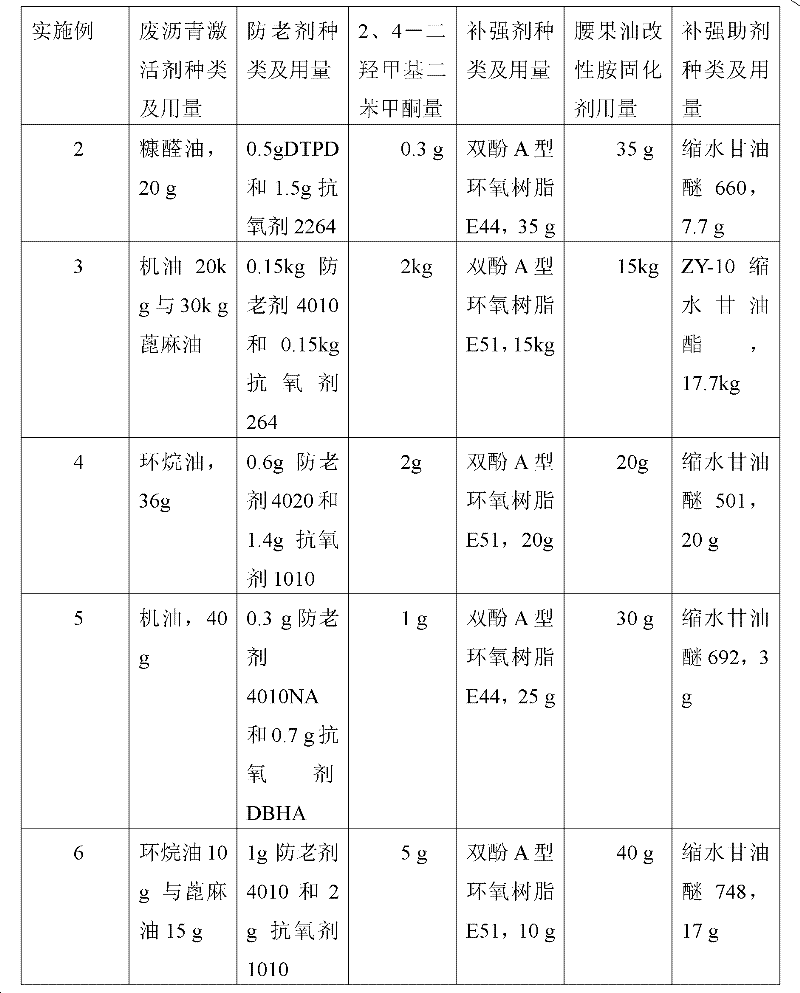

[0036] Embodiments 2-6: The asphalt cold rejuvenator was prepared according to the following materials and dosage, and the rest were the same as in Embodiment 1.

[0037]

[0038] Add the asphalt cold rejuvenator prepared according to the raw materials in the above table to the waste asphalt concrete at a weight ratio of 1% to 2% to the waste asphalt concrete to obtain a recycled asphalt mixture. The penetration at 25°C is 65-70, The ductility is greater than 100 at 15°C, and the softening point is 45-55.

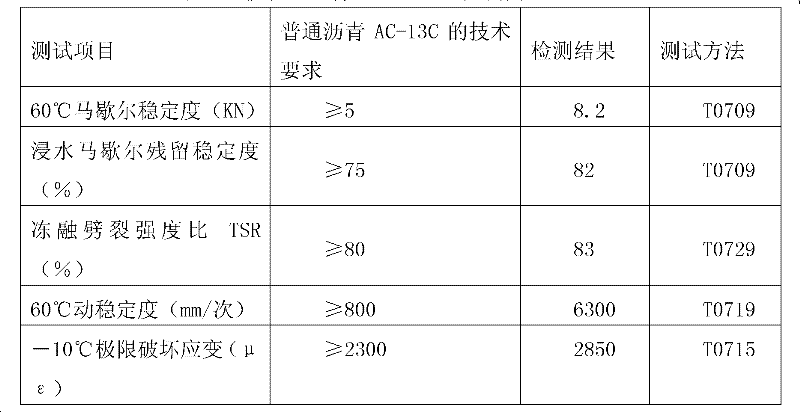

[0039] Heat the excavated or milled waste asphalt concrete to 60°C, gently crush it with a wooden stick, sieve, and then synthesize the gradation according to the AC-13C type gradation requirements, and finally according to the weight ratio of the waste asphalt concrete to 1.0~ Add 2.0% of the asphalt cold rejuvenator prepared in the above table, and after uniform mixing, form and test according to the standard "Asphalt and Asphalt Mixture Test Procedures", the Marshall st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com