Animal manure carbon fertilizer and production method thereof

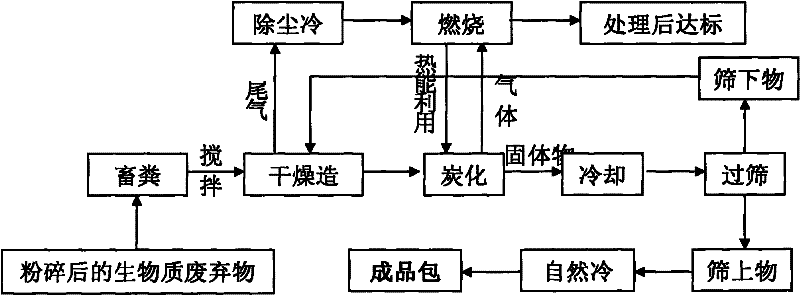

A production method and animal manure technology, applied in the direction of organic fertilizers, fertilization devices, excretion fertilizers, etc., can solve problems affecting the surrounding living environment, hidden dangers of human health, water environment pollution, etc., to enhance lodging resistance and improve micro-ecological environment , to avoid the effect of plant rot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

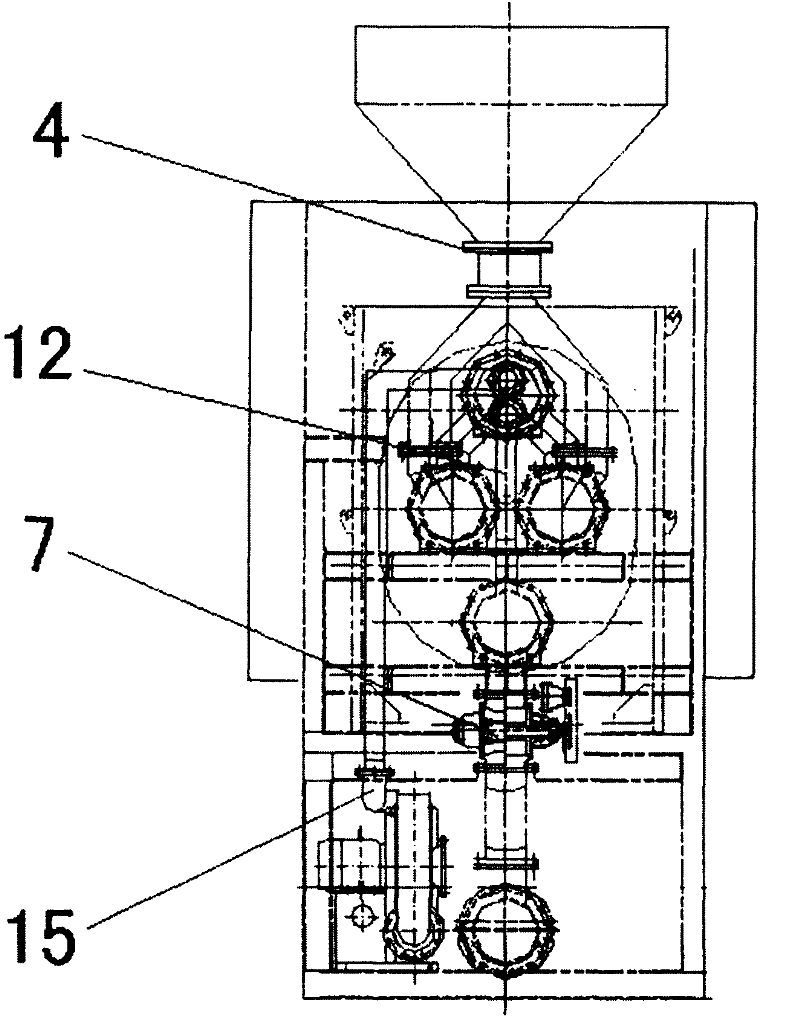

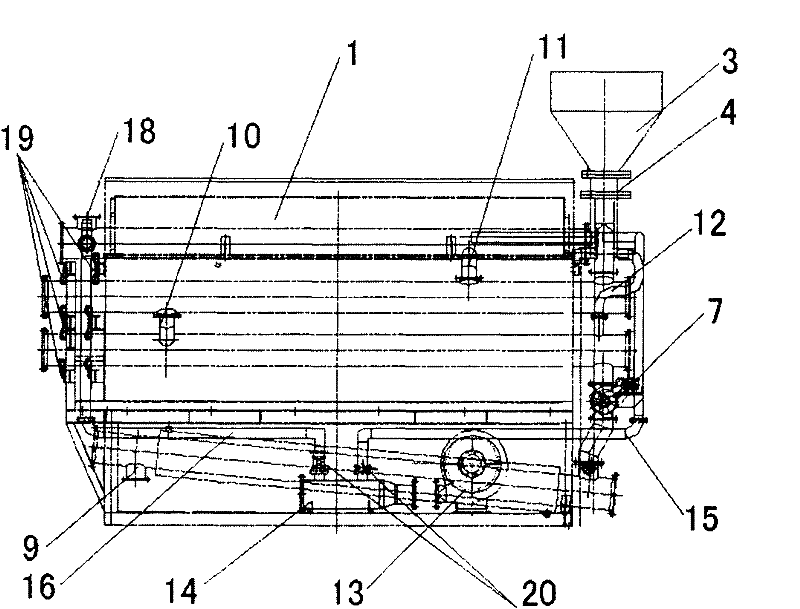

Image

Examples

Embodiment 1

[0107] Take 10 tons of cow dung (with a moisture content of 70%), spread it on the drying field, and dry it under direct sunlight until the moisture content is 40%, and obtain 5 tons of dry matter, which is transported to the KJG type through a closed screw conveyor. Paddle-type dryer, which uses high-temperature water as a heat source to indirectly heat and dry livestock manure (water temperature is 60-100°C). The moisture content of dried livestock manure reaches 20%, and the mass is about 3.7 tons. Then it enters the BMS type carbonization furnace through the closed spiral conveying pipe; the temperature of the carbonization furnace is preheated to 700°C, and it starts to receive dry animal manure. After 20 minutes of carbonization treatment, it becomes black carbonization. After the charcoal is cooled to 150°C by a tubular water cooling device, it enters the vibrating screen for sieving, and the sieved material is placed in a ventilated place (with no flammables around it) ...

Embodiment 2

[0117] Take 10 tons of pig manure (moisture content 80%), crush bamboo, branches, etc. into wood chips (bamboo chips) with a diameter of 1 to 10 mm, and take 5 tons, fully mix and stir, with a total weight of 15 tons; The material is transported to the KJG paddle dryer, and the heat-conducting oil is used for indirect heating (the temperature of the heat-conducting oil is 160 degrees Celsius) to heat and dry the material, and the material is fully mixed through the rolling and stirring of the blades inside the dryer. After 25 minutes, the material is dried to a moisture content of 30%, and enters the BMS sludge carbonization furnace through a closed screw conveying pipe; the temperature of the carbonization furnace is preheated to 760°C, and the material starts to be received. After 18 minutes of carbonization treatment, it becomes Black carbide. After the charcoal is cooled to 150°C by a tubular water cooling device, it enters the vibrating screen for sieving, and the sieved ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com