Method for improving resolution of inkjet printing by inducing de-infiltration of ink droplets based on external stimulus

An external stimulus and inkjet printing technology, applied in printing, ink, household appliances, etc., can solve the problems of small resolution range, poor universality of the method, cumbersome process, etc., and achieve high printing resolution and large range , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

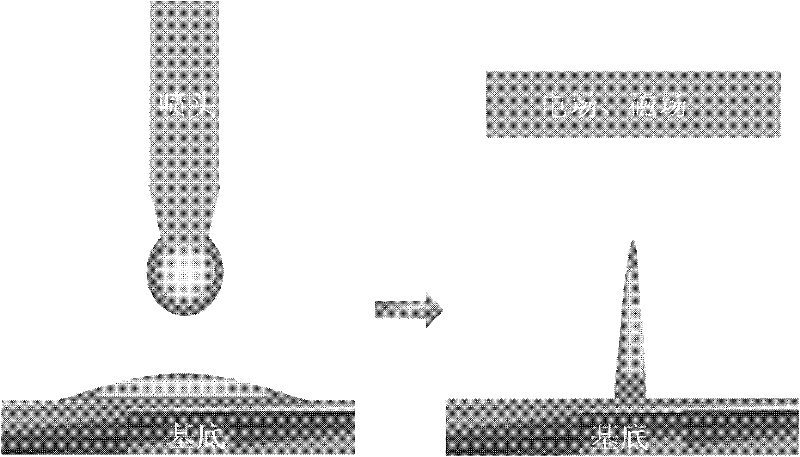

[0040] At room temperature (25°C), Fe with a particle size of 20 nm 3 o 4 The particles are dispersed in a polyurethane solution (20wt%) with a viscosity of 700mPa·s, Fe 3 o 4 The content of the particles in the polyurethane solution was 5 wt%. After mechanical dispersion, ultrasonication was performed for about 1 hour to obtain magnetic field responsive ink. Such as figure 1 As shown, the magnetic field-responsive ink is packed in the ink cartridge of the industrial dispensing system, equipped with a Picodot nozzle with an aperture of 150 μm. A block-shaped permanent magnet ferrite is arranged vertically above the PTFE film base material, and the magnetic field strength is 100 Gauss. The ink is sprayed from the nozzle to the PTFE film, and the newly printed PTFE film is placed under the above-mentioned permanent ferrite. The ink droplets sprayed on the surface of the PTFE film are applied to it before curing Attracted by the magnetic field strength of 100 gauss, the ink...

Embodiment 2

[0042] At room temperature, Fe with a particle size of 50 nm 3 o 4 The particles were dispersed in polyethylene glycol aqueous solution (50wt%) with a viscosity of 500mPa·s, Fe 3 o 4 The content of the particles in the polyethylene glycol aqueous solution is 10 wt%. Add crosslinking agent N, N-methylenebisacrylamide (content in polyethylene glycol aqueous solution is 10wt%) and photoinitiator 2-hydroxyl-2-methyl-1-phenyl-1-propanone (in The content in polyethylene glycol aqueous solution is 5wt%). After mechanical dispersion, ultrasonication is performed for about 1 hour to obtain magnetic field responsive ink. The magnetic field-responsive ink was packed in the ink cartridge of the industrial dispensing system, equipped with a Picodot nozzle with an aperture of 150 μm. A sintered lump RuFeB permanent magnet is arranged vertically above the polyethylene film substrate, and the magnetic field strength is 150 gauss. The ink is sprayed from the nozzle to the polyethylene fil...

Embodiment 3

[0044] At room temperature, Fe with a particle size of 100 nm 2 o 3 The particles are dispersed in polyethylene glycol-diacrylic acid water dispersion system (20wt%) with a viscosity of 300mPa·s, Fe 2 o 3 The content of the particles in the polyethylene glycol-diacrylic acid water dispersion system is 15wt%. Add crosslinking agent N, N-methylenebisacrylamide (content in polyethylene glycol-diacrylic acid water dispersion system is 5wt%) and photoinitiator 1-hydroxycyclohexyl phenyl ketone (in polyethylene glycol The content in the alcohol-diacrylic acid water dispersion system is 1wt%), after mechanical dispersion, ultrasonication is performed for about 1 hour, and the ink with magnetic field responsiveness is obtained. The magnetic field-responsive ink was packed in the ink cartridge of an industrial dispensing system equipped with a Picodot nozzle with an aperture of 150 μm. A sintered bulk RuFeB permanent magnet is arranged vertically above the PDMS film substrate, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com