Method for grinding indium antimonide wafer

An indium antimonide wafer and indium antimonide technology are applied in grinding/polishing equipment, grinding/polishing safety devices, and machine tools suitable for grinding workpiece planes, etc. Inefficiency and other problems, to achieve the effect of reducing edge collapse, improving yield, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

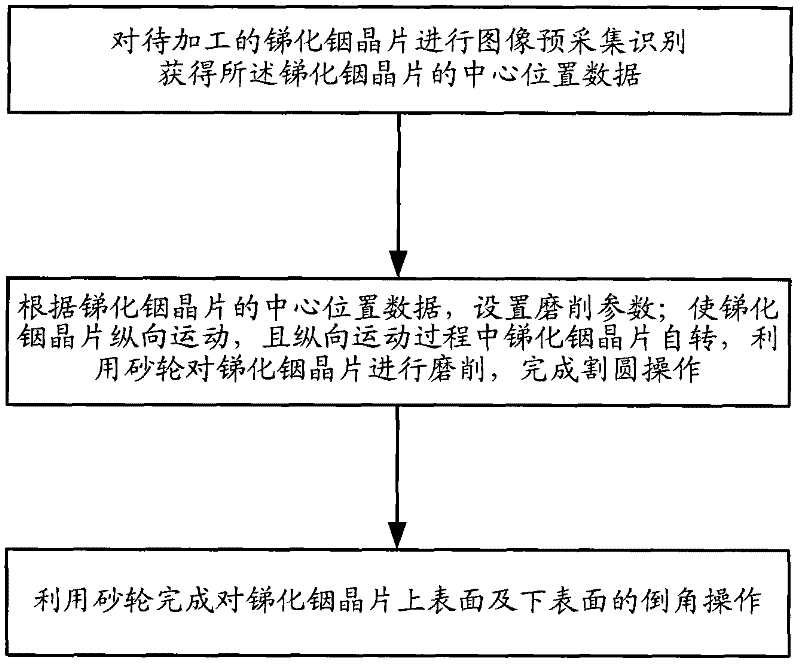

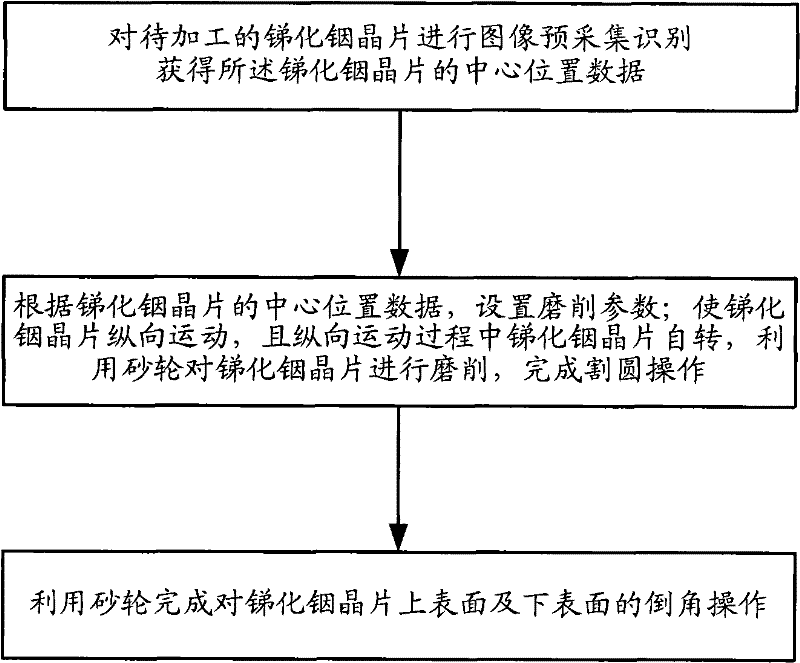

[0022] In order to solve the problem of circle cutting and chamfering process of 3-inch indium antimonide wafer, the present invention provides a wafer shape recognition based on wafer image recognition technology and matching process of cutting circle and chamfering indium antimonide wafer, which not only solves the problem of It solves the problems of accuracy, poor consistency, and high labor intensity of the existing manual processing technology, and effectively solves the problem of batch and large-scale production of indium antimonide wafers, and provides a method for dividing the plane into circles and concaves in multiple steps after wafer identification. The subsequent treatment proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com