Pressure bonding device and pressure bonding method

A technology of a crimping device and a crimping unit, which is applied to optics, instruments, electrical components, etc., can solve the problems of decreased utilization efficiency, hindered production efficiency, and hindered production efficiency, so as to improve the utilization efficiency and shorten the moving distance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

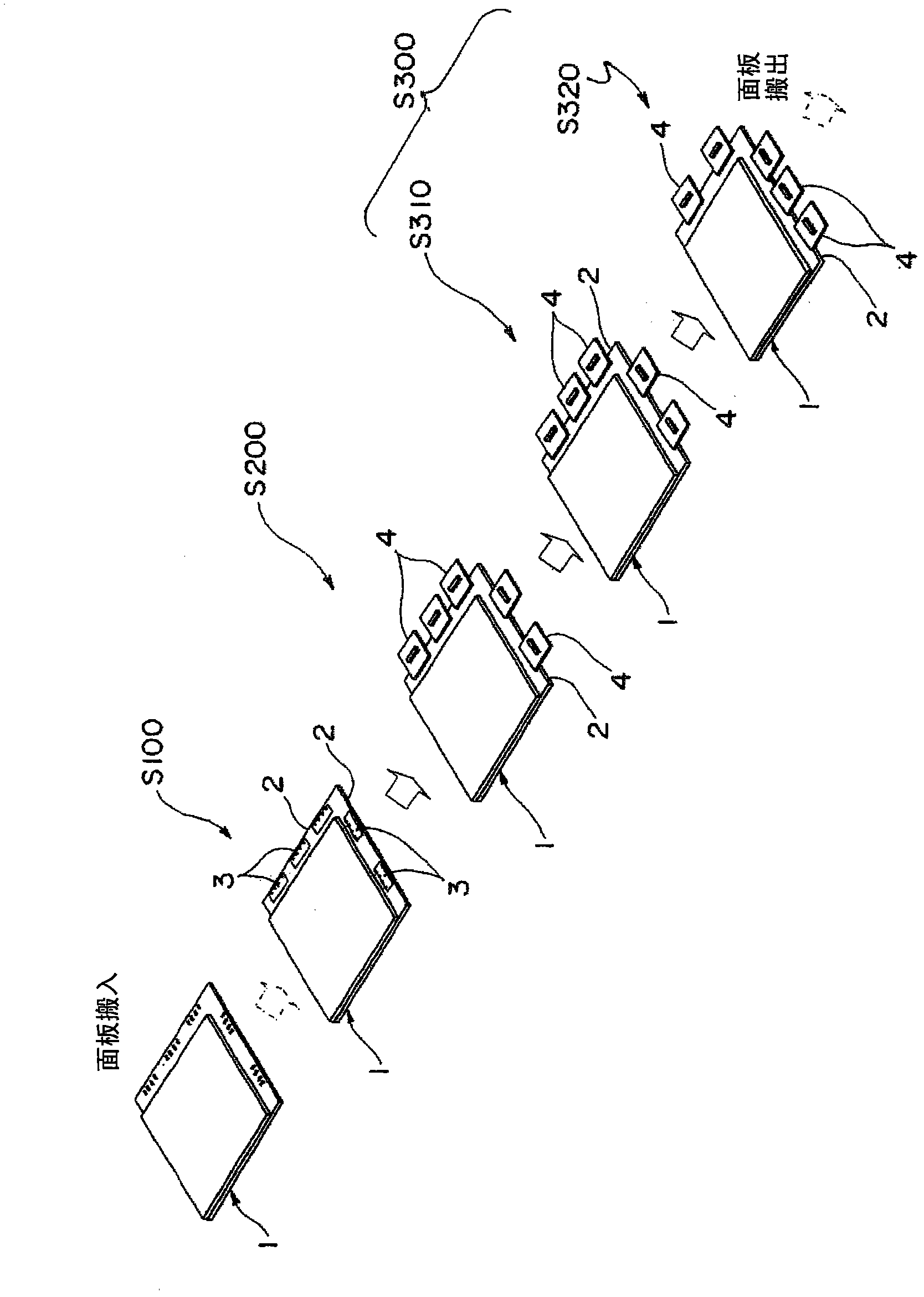

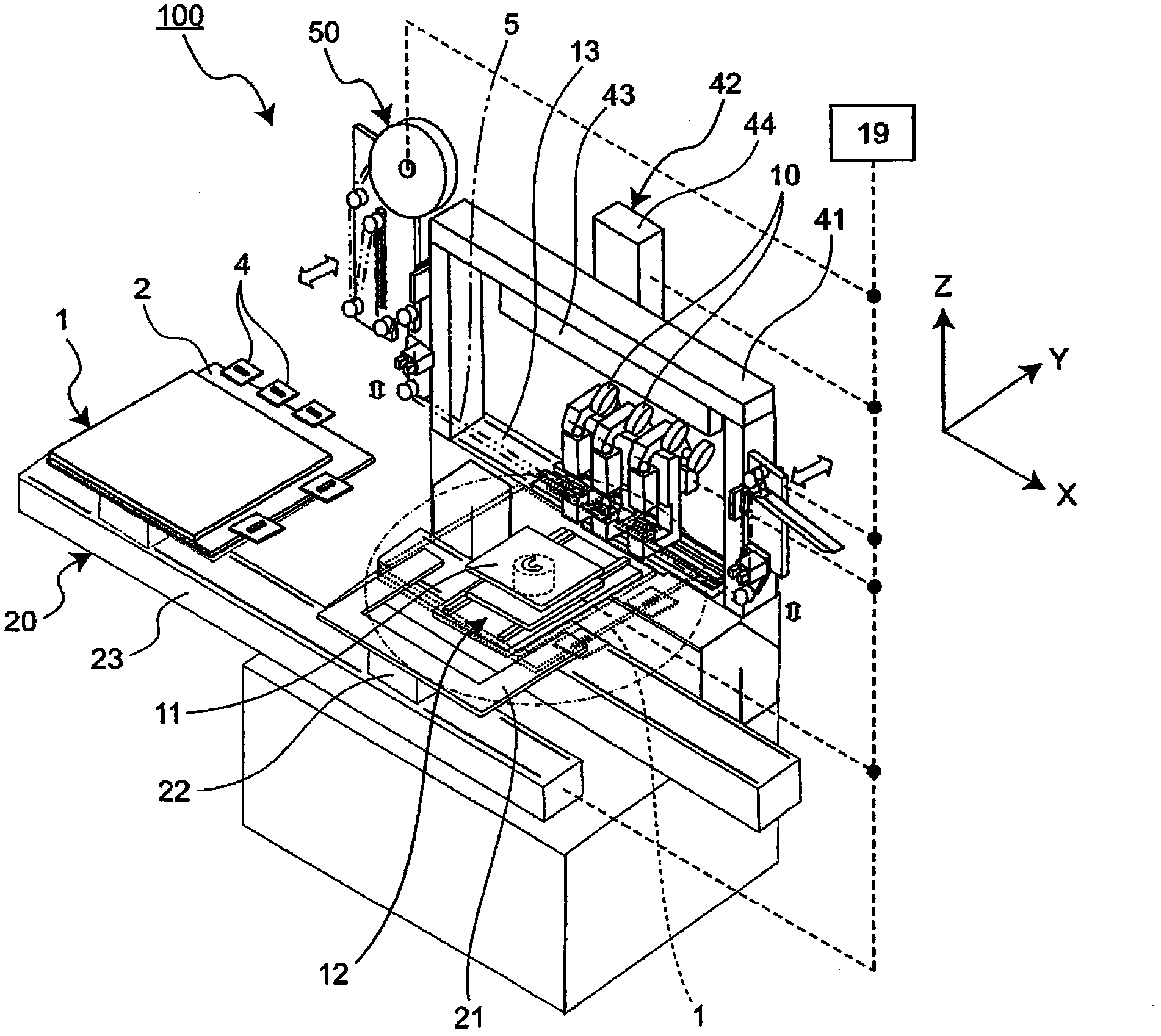

[0086] As an example of the crimping device and method according to the first embodiment of the present invention, a component crimping device and a component crimping method will be described. First, using the figure 1 The form of the panel substrate 1 processed in the above-mentioned component pressure-bonding apparatus and method and the outline of the pressure-bonding process (or mounting process) performed on the panel substrate 1 will be described.

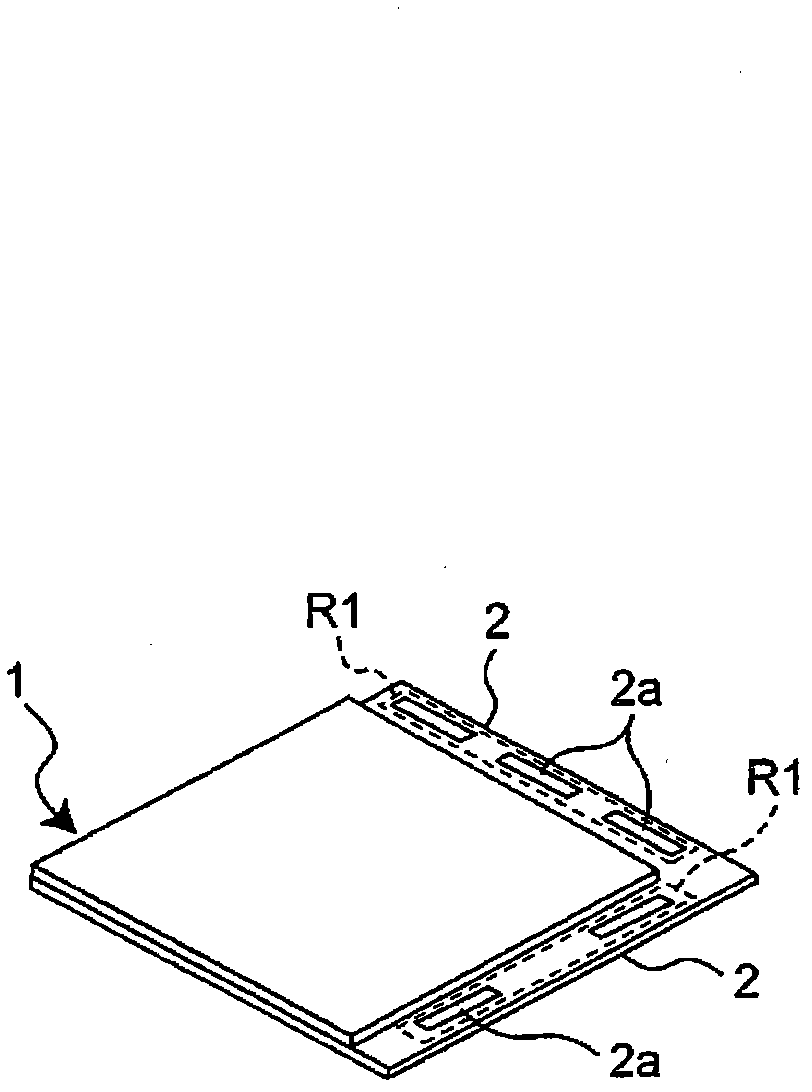

[0087] First, if figure 1 As shown, the substrate to be processed in the first embodiment is a substrate represented by a liquid crystal display (LCD) panel substrate, a plasma display panel (PDP) substrate, etc. (hereinafter referred to as "panel substrate") 1, which Edges of two sides adjacent to each other in the square shape have terminal portions 2 on which component mounting regions R1 for mounting components are disposed. It should be noted that such a panel substrate 1 generally has a rectangular shape, and each te...

no. 2 approach

[0147] Next, a crimping method according to a second embodiment of the present invention will be described. The crimping method of the second embodiment is characterized in that the actual crimping device 100 of the above-mentioned first embodiment can selectively respond to the tact of the actual crimping action issued by the operator in terms of control. Prioritize the request or respond to the request from the operator to prioritize the utilization efficiency of the protective sheet. Hereinafter, the crimping method of the second embodiment will be specifically described.

[0148] Here, in order to describe the crimping method of the second embodiment, the moving operation of the protection sheet 5 in the actual crimping device 100 will be summarized. The switching of the contact position of the crimping head 31 relative to the protective sheet 5 by moving the protective sheet 5 in the Y-axis direction, that is, the width direction, by the Y-axis direction sheet moving dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com