Heat exchanger element

A technology of heat exchangers and components, applied in heat exchange equipment, laminated components, indirect heat exchangers, etc., can solve problems such as high conductivity, high manufacturing cost, and easy to produce defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

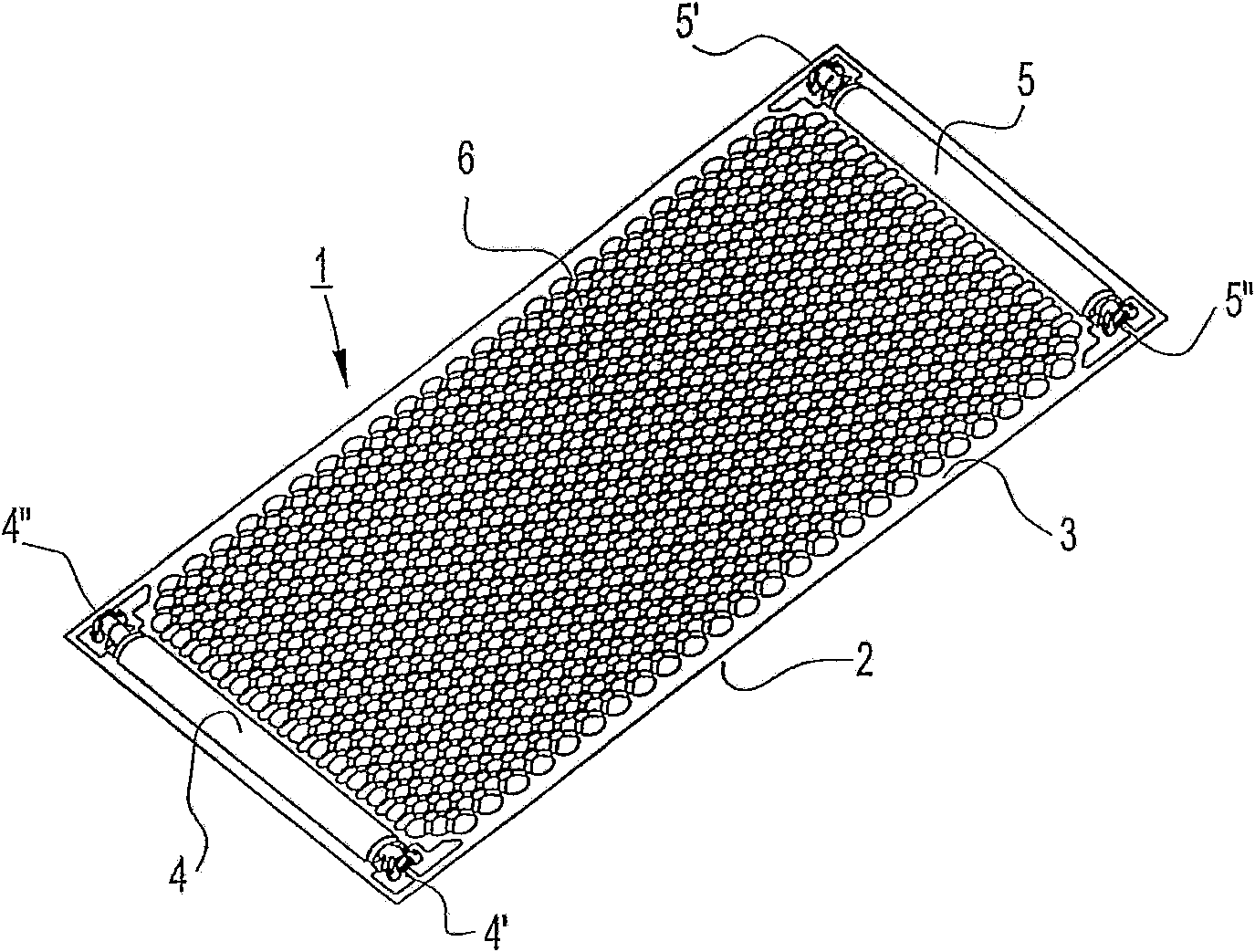

[0026] in figure 1 with figure 2 In, the first embodiment of the heat exchange element 1 according to the present invention is schematically shown. The element 1 has a flat first rectangular plate 2 and a second rectangular plate 3 showing a pattern. When connected, the second plate and the first plate 1 together define the inlet channel 4 and the outlet channel 5 and the A passage 6 extending between the inlet and the outlet.

[0027] The two rectangular plates are made of 1mm thick thermoplastic material (ABS). The most important mechanical properties of ABS are resistance and toughness, but it can also be modified in many ways to improve its impact resistance, toughness, heat resistance and UV resistance. It is also a thermoplastic material that can be heated and given a certain shape, which will maintain that shape when the temperature returns again below the point where plastic deformation is allowed.

[0028] The pattern formed in the second plate 3 can be described as top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com