Method for polymerising glycolic acid with microorganisms

A technology of glycolic acid and microorganisms, applied in the direction of fermentation, etc., can solve problems such as the homopolymer method of glycolic acid that has not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

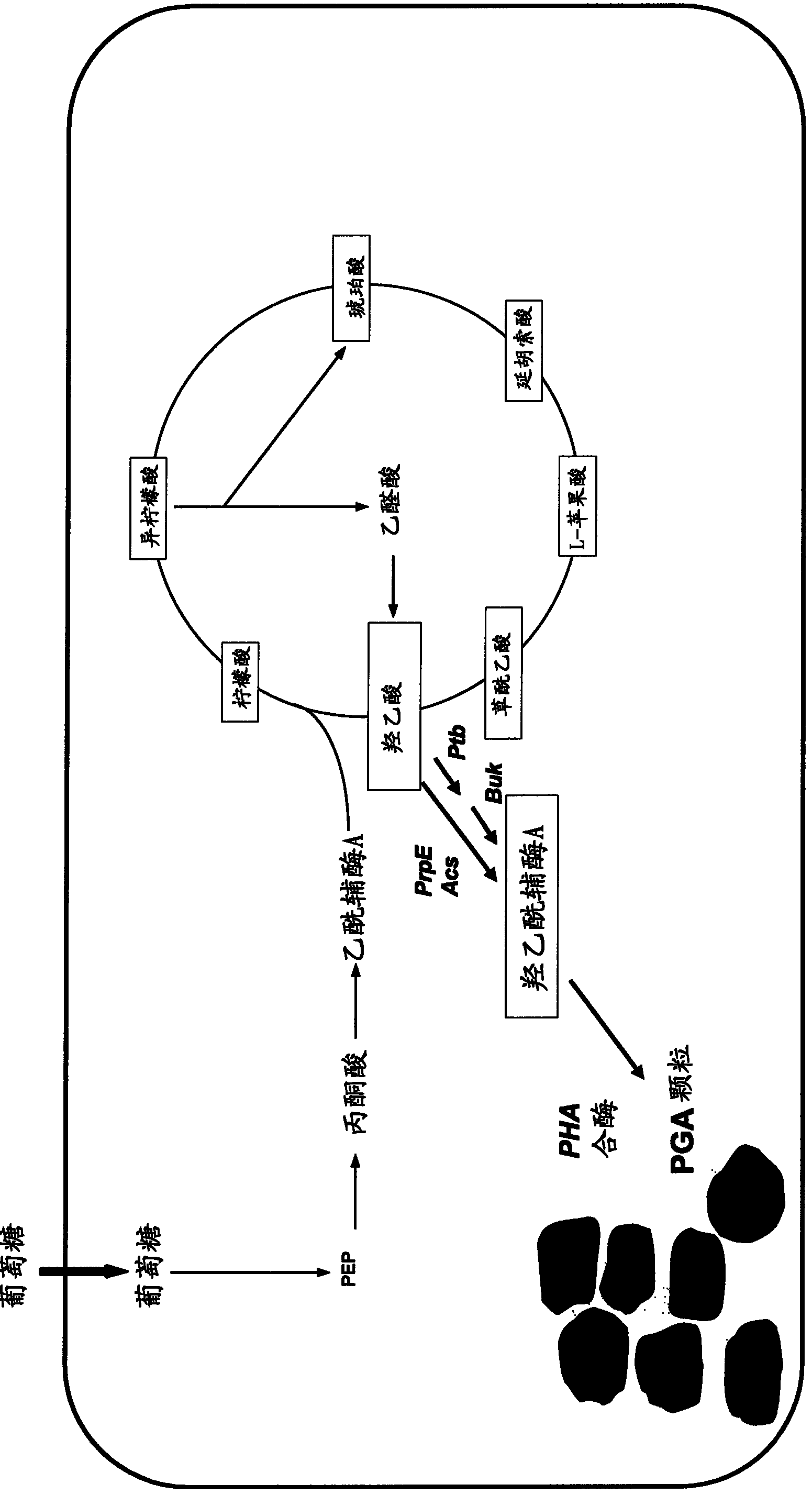

Method used

Image

Examples

Embodiment 1

[0094] Construction of Recombinant Vector Containing Encoding Acyl-CoA Synthetase

[0095] Construction of pSCB-acs, pSCB-prpE and pSCB-prpEst

[0096] Glycolic acid is converted to glycolyl-CoA using two proteins, either propionyl-CoA synthase, prpE (from E. coli or S. typhimurium), or acetyl-CoA synthase, encoded by acs. Each gene was co-expressed intracellularly with the gene phaC1 encoding PHA synthase from R. eutrophica.

[0097] To amplify the acs and prpE genes, use the chromosomal DNA of E. coli as a template, and use the above primers (see Table 1), the primers for acs amplification are called acs F and acs R, and the primers for prpE amplification Called prpE F and prpE R, PCR was performed.

[0098] The PCR fragment of acs was cloned into the vector pSCB (Stratagene Blunt PCR Cloning KitCAT 240207-5) to obtain the plasmid pSCB-acs.

[0099] The PCR fragment of prpE was cloned into vector pSCB to obtain plasmid pSCB-prpE.

[0100] To amplify the gene prpE from Sa...

Embodiment 2

[0103] Construction of recombinant vectors containing genes encoding PHA synthase and acyl-CoA synthase

[0104] Construction of pMK-Ptrc01 / OP01 / RBS01-phaC1re-TT02

[0105] The plasmid carrying the gene phaC1 from R. eutrophica was provided by a company that synthesized the gene with an optimized sequence for optimal transcription rate in E. coli.

[0106] The relative frequency of codons varies widely depending on the organism and organelle. Many design programs for the synthesis of protein coding sequences allow selection of organisms. codon usage database Codon usage statistics are available for many commonly used and sequenced organisms such as E. coli.

[0107] The synthetic gene phaC1 encoding PHA synthase was provided ready-to-use by the company. The gene was cloned under the Ptrc01 promoter with an operator, the RBS sequence (SEQ NO: 1) located upstream of the gene, and the terminator sequence located downstream of phaC1re, resulting in plasmid pMK-Ptrc01 / OP01 / RBS0...

Embodiment 3

[0117] Construction of recombinant E. coli strains that produce PGA when cultured in the presence of glycolic acid and production of polyglycolic acid polymers

[0118] The vectors pMK-Ptrc01 / OP01 / RBS01-phaC1re-acs-TT02 and pMK-Ptrc01 / OP01 / RBS01-phaC1re-prpE-TT02 were introduced into Escherichia coli MG1655 wild-type strain by electroporation to obtain strain MG1655 (pMK-Ptrc01 / OP01 / RBS01-phaC1re-acs-TT02) and MG1655 (pMK-Ptrc01 / OP01 / RBS01-phaC1re-prpE-TT02).

[0119] The vectors pBBRMCS5-Ptrc01 / OP01 / RBS01-phaC1re-prpEst-TT02 and pUC19-Ptrc01 / OP01 / RBS01-phaC1re-prpEst-TT02 were introduced into the Escherichia coli MG1655 wild-type strain by electroporation, and the bacterial strain MG1655 (pBBRMCS5-Ptrc01 / OP01 / RBS01-phaC1re-prpEst-TT02) and MG1655 (pUC19-Ptrc01 / OP01 / RBS01-phaC1re-prpEst-TT02).

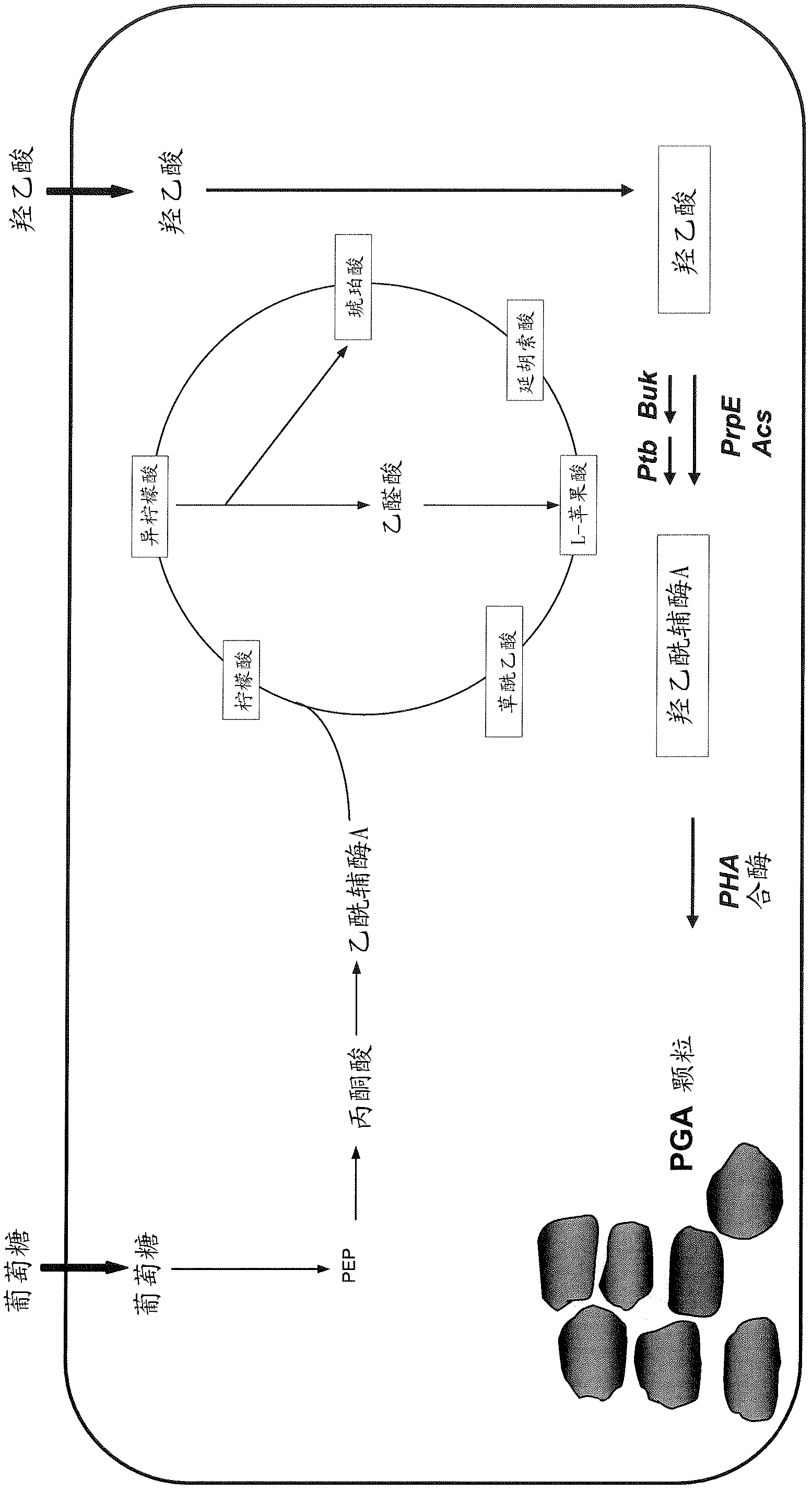

[0120] The resulting strain ( figure 2 ) were cultured in LB or MM medium containing about 5 g / L glycolic acid (the details of the conditions are in the following examples), and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com