Electrical control variable plunger pump and pump control hydraulic system thereof

A technology of variable plunger and plunger pump, which is applied in the direction of fluid pressure actuated system components, pump control, liquid variable capacity machinery, etc. It can solve the problem of insufficient load driving force, difficulty in quick response, and slow response of variable frequency variable speed system and other issues, to achieve fine control of flow output and pressure output, improve efficiency and control accuracy, and achieve flexible composition and layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further described below in conjunction with the accompanying drawings.

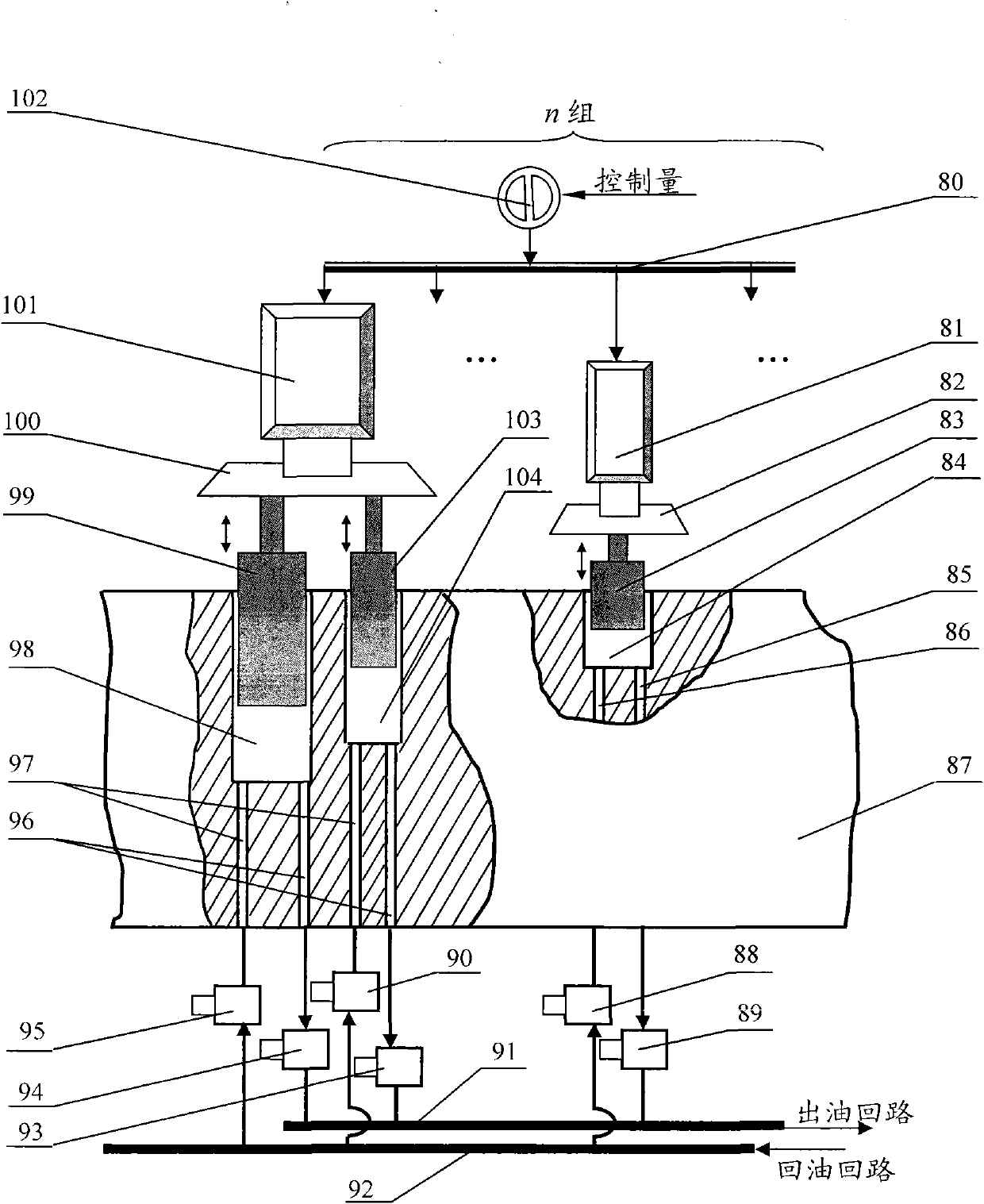

[0081] in the attached figure 1 In , a schematic diagram of the structure of an electronically controlled variable displacement pump is given. The text "n group" in the figure means that there are n plunger groups in a pump (a natural number of n≥2), and the ellipsis in the figure indicates other plunger groups of the n groups of plunger groups that are not shown in the figure. There are two sets of plunger sets, one set of two plungers and one set of one plunger.

[0082] attached figure 1 The electric device 101 of one plunger group is connected to one end of the corresponding mechanical connection device 100 , and the other end of the mechanical connection device 100 is connected to one end of the two plungers 99 , 103 . The plunger hole on the plunger 99, the plunger 103 and the corresponding cylinder block 87, and the oil inlet passage 97, the oil outlet passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com