Thermal Control Device of Radar Antenna Transceiver Components

A technology for transceiver components and radar antennas, applied to antenna components, antennas, antennas suitable for movable objects, etc., can solve problems such as the inability to meet the working temperature range and temperature difference requirements of radar antenna transceiver components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

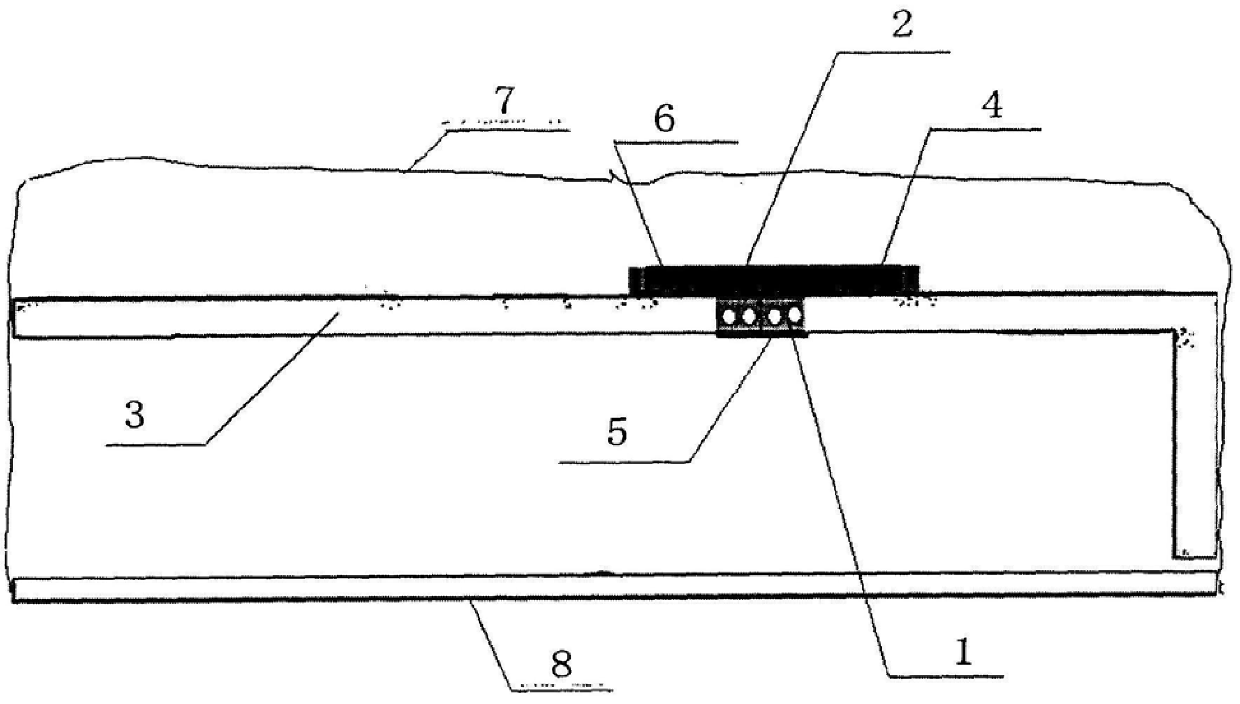

[0013] Below in conjunction with the accompanying drawings illustrate preferred embodiments of the present invention.

[0014] The design of the thermal control device of the radar antenna transceiver assembly not only has temperature range requirements, but also temperature difference requirements. this invention

[0015] The design of the thermal control device of the transceiver assembly of the present invention is mainly carried out around the above characteristics.

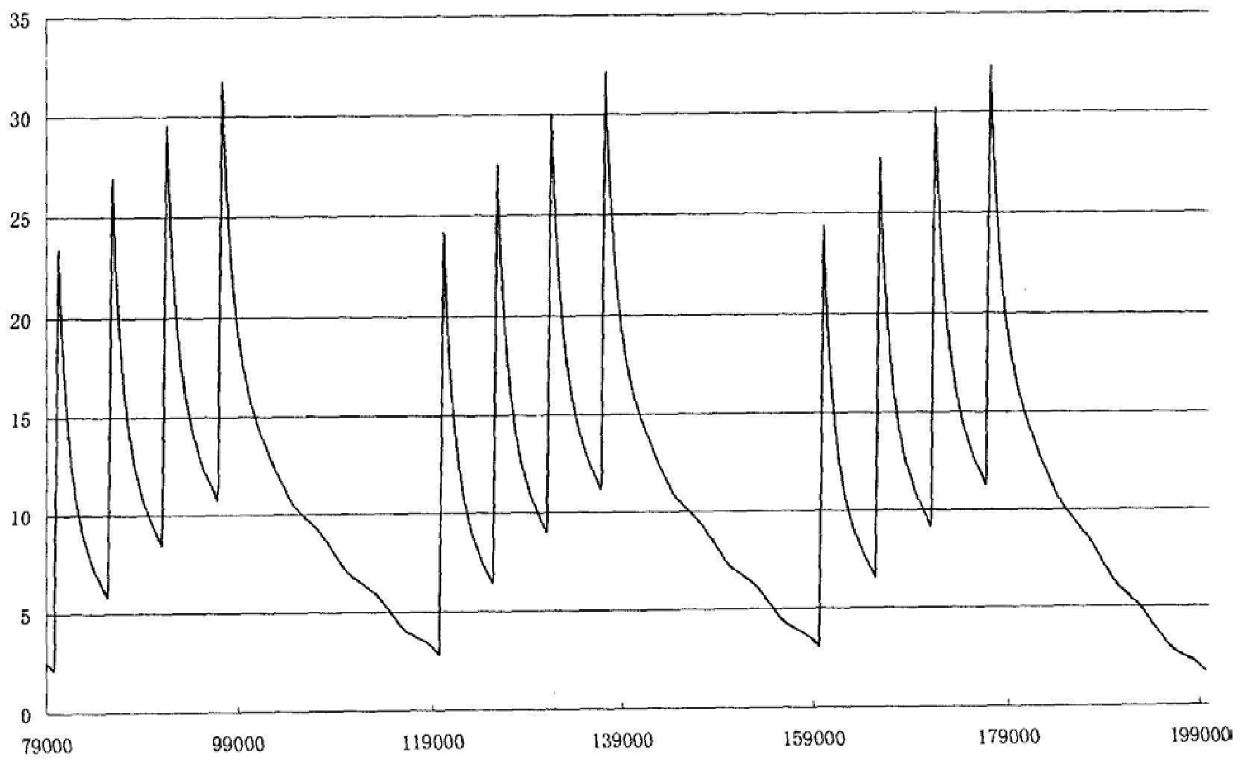

[0022] 2) The maximum temperature difference between the 560 transceiver components at the same time is 3°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com