Suspended dielectric combline cavity filter

一种梳状线、电介质的技术,应用在在空腔上悬挂陶瓷谐振器的结构领域,能够解决昂贵、费时、使用复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Referring now to the drawings, in which like numerals refer to like components or steps, broad aspects of various exemplary embodiments are disclosed.

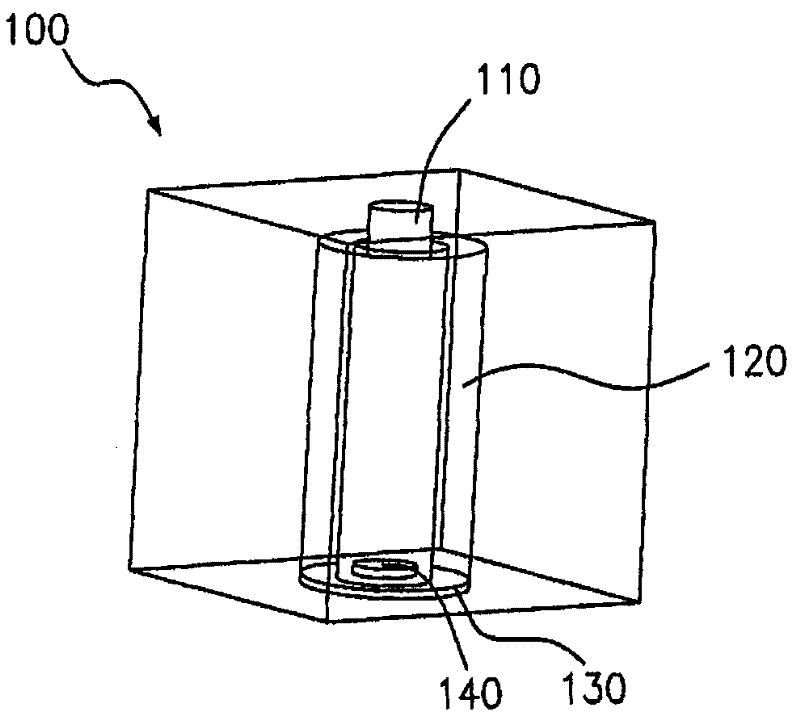

[0029] figure 1 is a perspective view of an exemplary suspended TM mode dielectric combline cavity 100 . In various exemplary embodiments, cavity 100 includes tuning element 110 , resonator 120 , support plate 130 , and mounting element 140 . Cavity 100 is defined by at least one conductive wall. In various exemplary embodiments, such walls may be metallic, or made of metallized polymers.

[0030] In various exemplary embodiments, cavity 100 has a cuboid shape. Therefore, the cavity 100 may include a top surface, a bottom surface and four side walls. As will be apparent to those skilled in the art, cavity resonators may be fabricated in shapes other than cuboids, such as spheres or cylinders, and the like.

[0031] In various exemplary embodiments, tuning element 110 extends downwardly from the top surface of cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com