Apparatus and method for preparing titanium dioxide sol, and paste composition prepared using same

一种二氧化钛、制备装置的技术,应用在二氧化钛、氧化钛/氢氧化物、用于材料和表面科学的纳米技术等方向,能够解决不适合大批量生产、工艺复杂、量产性及经济性差等问题,达到优越长期贮藏性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

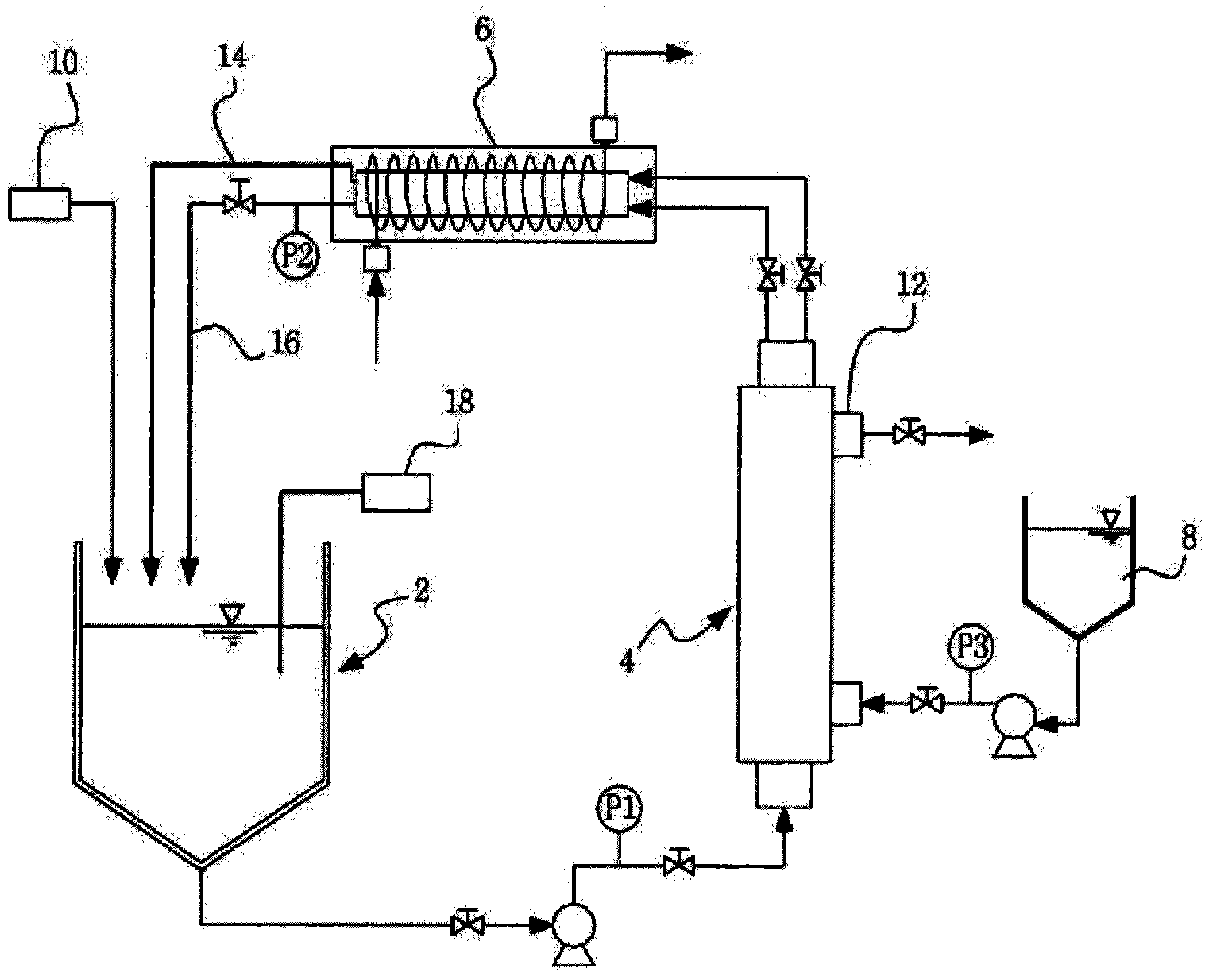

[0028] According to another point of view, the preparation method of titanium dioxide sol provided by the present invention includes the following steps: (a) mixing 1-30 parts by weight of a dispersion stabilizer and 70-99 parts by weight of an organic solvent to prepare a sol containing a dispersion stabilizer Organic solvent mixture; (b) mixing the organic solvent mixture containing the dispersion stabilizer in the step (a) with the aqueous titanium dioxide sol at a volume ratio of 1:1 to 1:9 to prepare the aqueous titanium dioxide sol containing the dispersion stabilizer (c) using a separation unit to separate the organic solvent mixture containing aqueous titanium dioxide sol and dispersion stabilizer in step (b) into titanium dioxide particles and an organic solvent mixture containing water and dispersion stabilizer, and using an organic solvent to replace water for solvent replacement; (d) circulating and mixing the titanium dioxide particles separated according to the so...

Embodiment 1

[0077] Based on the overall weight of the mixture, 5% by weight of acetylacetone [Junsei, Japan] as a dispersion stabilizer was added to 99% pure ethanol [Samcheon, Republic of Korea] as an organic solvent, An organic solvent mixture containing a dispersion stabilizer was prepared in a total volume of 1 L, and then the mixture was stirred for about 30 minutes.

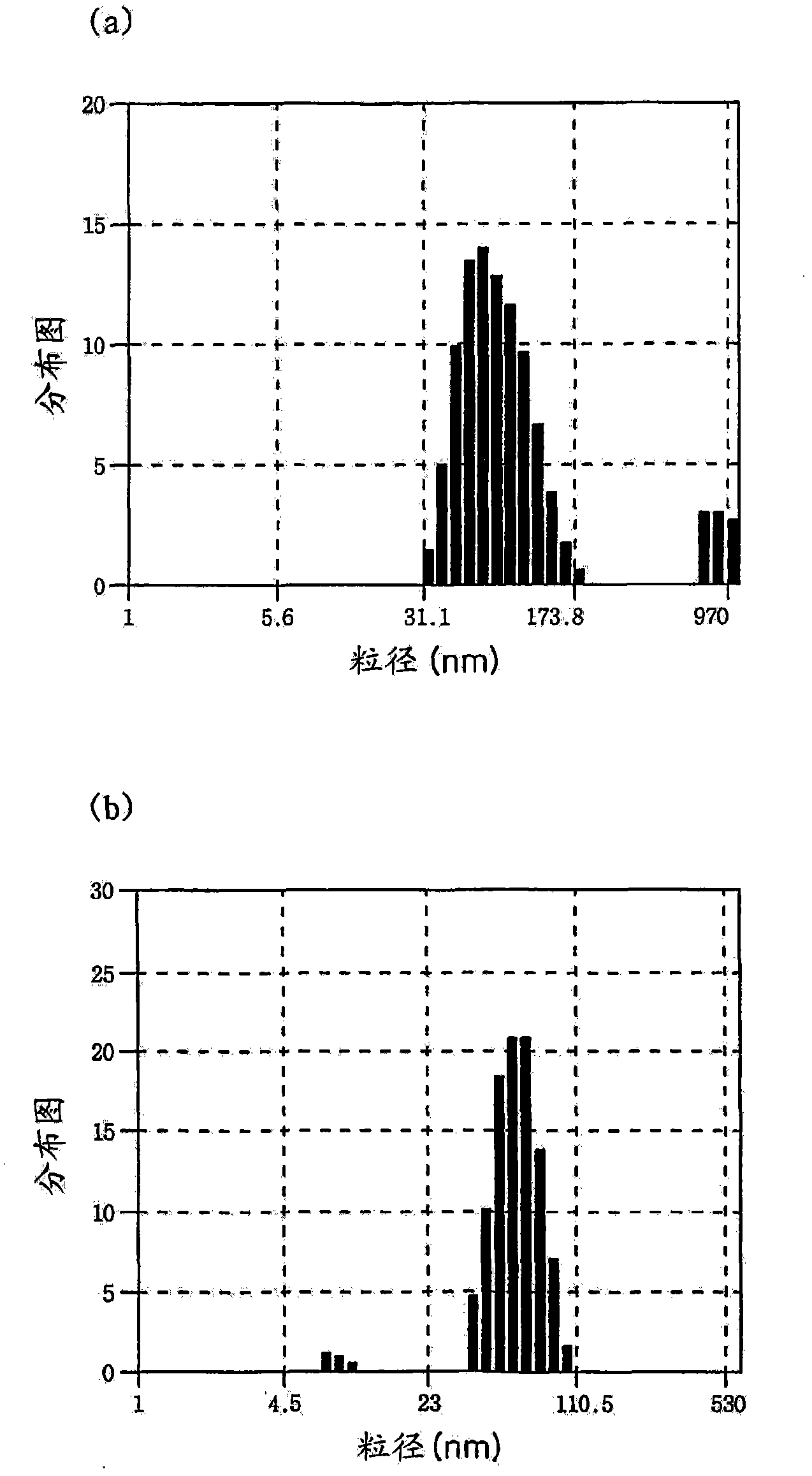

[0078] Next, after fully stirring the aqueous TiO2 sol [S5-300A, millennium chemicals, the United States] and the organic solvent mixture containing the dispersion stabilizer at a volume ratio of 1:1, at a temperature of 20°C, use figure 1 The titanium dioxide preparation device of the company repeatedly executes the process until the ethanol replaced by the solvent reaches more than 95%, so as to prepare the titanium dioxide sol replaced by the ethanol solvent.

[0079] At this time, an ultrafiltration membrane [UF membrane system, Kemicore, Korea] was used as the separation unit, and a heat exchanger [Heat exchanger,...

Embodiment 2

[0085] It was carried out in the same manner as in Example 1, except that 99% pure methanol (Samcheon, Korea) was used instead of 99% pure ethanol (Samcheon, Republic of Korea).

[0086] The result is expressed in Figure 4 and Figure 5 .

[0087] Such as Figure 4 As shown, the viscosity change chart with time of the titania sol replaced by the ethanol solvent of Example 1 and the titania sol replaced by the methanol solvent of Example 2 is shown, thus it can be found that the respective initial viscosities of 7cP and 8cP viscosities even After 30 days there was little change. This shows that the solvent-substituted titanium dioxide sols of Examples 1 and 2 can maintain their stability even after long-term storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com