Method and equipment for heating semiconductor device

A heating device and heating method technology, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve the problems of low reliability, high cost of heating plates, limited heat dissipation, etc. High reliability, uniform temperature rise of the system, and the effect of avoiding excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

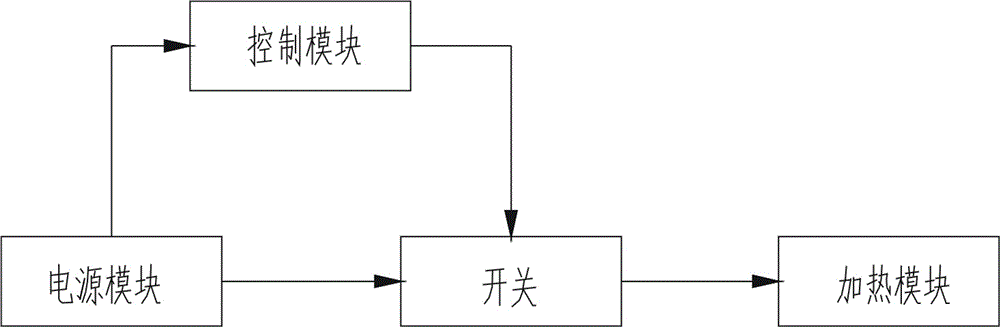

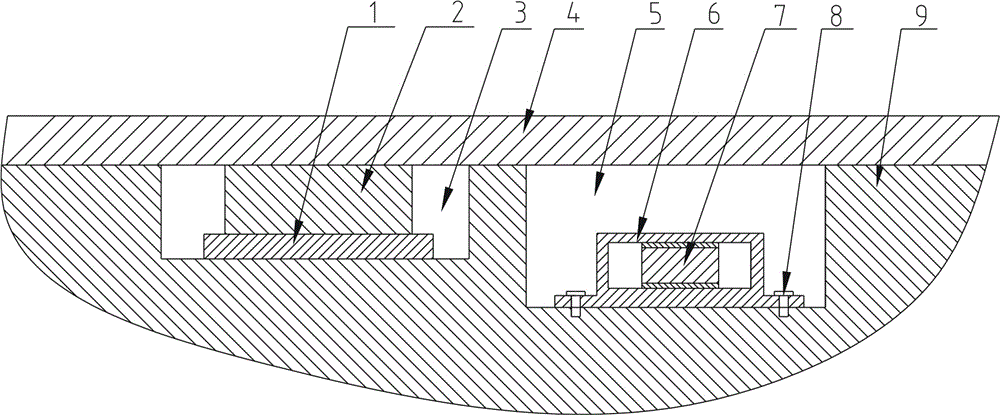

[0025] The semiconductor device heating method and device of the present invention achieve the purpose of heating the semiconductor device by heating the base, therefore, the temperature rise of the system is relatively uniform, the temperature difference between the upper and lower surfaces of the semiconductor device is small, and the solder fillet will not cause stress deformation due to excessive temperature difference, etc. On the downside, the heating is very reliable. The electric heating body heats the semiconductor device to the start-up temperature at low temperature. When the semiconductor device is working normally, the electric heating body is turned off, and the heat dissipation of the semiconductor device will not be affected. It is especially suitable for the heating requirements of the back-mounted semiconductor device. Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] figure 1 Shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com