Screw-hole-free hot pressing head locking jig

A technology for locking fixtures and hot indenters, applied in presses, manufacturing tools, etc., can solve problems such as changes in the surface flatness of the indenter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

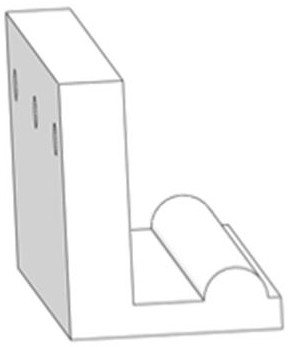

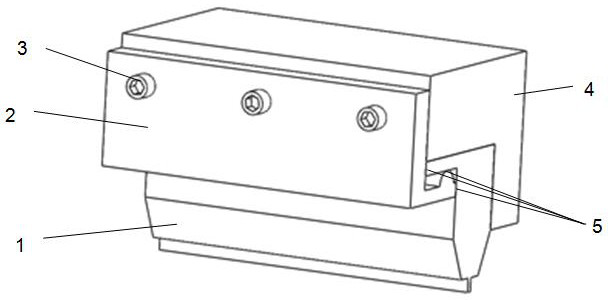

[0013] Depend on image 3 It can be seen that a thermal head locking fixture without screw holes includes a pressure head 1 and a pressure head locking block 2 . Stove head 4 is machine table fixing mechanism, plays heating effect. When installing, put the pressure head 1 close to the furnace head 4, and then lock the pressure head locking block 2 on the furnace head 4 with the inner hexagonal screw 3. After locking, the pressure head 1 is close to the furnace head 4. The heat conduction is good, and the pressure head 1 There are 3 contact surfaces with the pressure head locking block 2, which can lock the pressure head. Because of the surface contact, the force is relatively uniform, there is no stress deformation, the pressure head 1 has good flatness, and the quality of the produced products is guaranteed. .

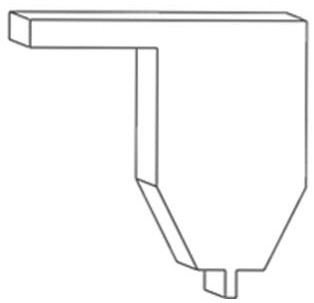

[0014] There is no screw hole on the whole body of the pressure head, and the pressure head is inverted L-shaped, which can be close to the furnace head. The press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com