Quantum size zinc oxide and preparation method and application thereof

A technology of zinc oxide and size, which is applied in the direction of zinc oxide/zinc hydroxide, measuring devices, instruments, etc., can solve the problems that quantum-sized zinc oxide crystals cannot be prepared, and the preparation method of quantum-sized zinc oxide is not mature enough to achieve structural stability , short reaction time and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Accurately weigh 0.2195g Zn(Ac) 2 2H 2 O and 0.06g NaOH were respectively dissolved in 20ml of absolute ethanol, under magnetic stirring at a rotational speed of 200rpm, slowly added the prepared NaOH-ethanol solution into the above Zn salt solution, so that the pH value of the mixed solution was about 12 , continue stirring for 1h. Accurately weigh 0.09 g of oleic acid, add it into the above reaction solution, and stir magnetically for 1 h. The obtained white jelly liquid was centrifuged at a speed of 3000r / s, and washed 2 to 3 times with absolute ethanol, and the white jelly obtained by centrifugation was dried at 50°C for 5 hours, and the temperature was raised to 200°C at a heating rate of 10°C / min. ℃, kept for 60 minutes, to obtain zinc oxide powder with quantum size.

[0024] According to the above experiment, except that oleic acid is not added, the prepared zinc oxide is very easy to agglomerate, and the particle size increases significantly.

[0025] The zi...

Embodiment 2

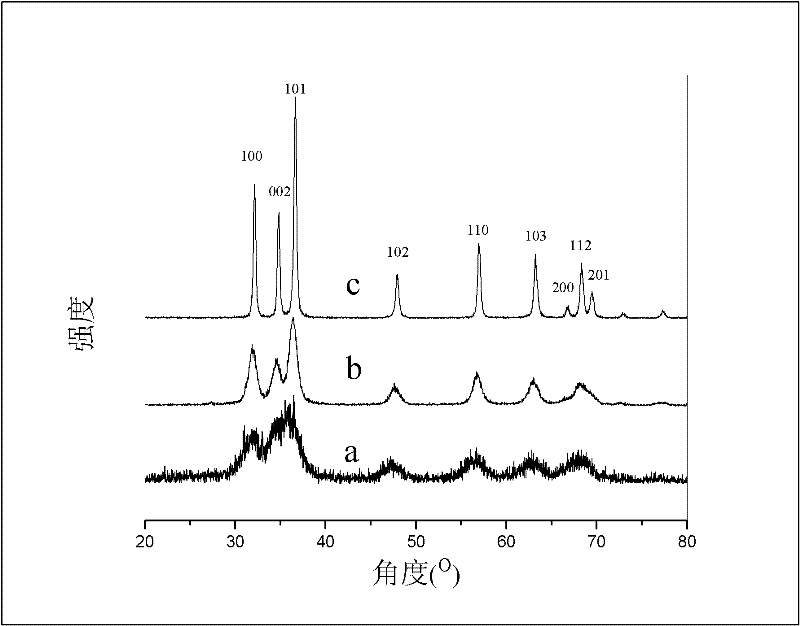

[0028] Accurately weigh 0.1785g Zn(NO 3 ) 2 ·6H 2 O and 0.12g NaOH were respectively dissolved in 20ml of absolute ethanol, under magnetic stirring at a rotational speed of 200rpm, slowly added the prepared NaOH-ethanol solution into the above Zn salt solution, so that the pH value of the mixed solution was about 12 , continue stirring for 1h. Accurately weigh 0.09 g of oleic acid and add it to the above reaction solution, and magnetically stir for 1 h. The obtained white jelly liquid was centrifuged at a speed of 3000r / s, and washed 2 to 3 times with absolute ethanol, and the white jelly obtained by centrifugation was dried at 50°C for 5 hours, and the temperature was raised to 400°C at a heating rate of 10°C / min. ℃ and kept for 60 min, a sample with a diameter of about 7 nm was obtained. PL from quantum-sized ZnO ( figure 2 b) The fluorescence effect of baking at 400°C can be seen. From the XRD of quantum size zinc oxide ( image 3 b) The degree of crystallization of...

Embodiment 3

[0030] Confirm that 0.191g ZnCl and 0.09g NaOH are dissolved in 20ml absolute ethanol respectively, and under magnetic stirring at 200rpm, the NaOH-ethanol solution prepared is slowly added dropwise to the above-mentioned Zn salt solution to make the mixed solution The pH value is about 12, continue to stir for 1h. Accurately weigh 0.09 g of oleic acid and add it to the above reaction solution, and magnetically stir for 1 h. The obtained white jelly liquid was centrifuged at a speed of 3000r / s, and washed 2 to 3 times with absolute ethanol, and the white jelly obtained by centrifugation was dried at 50°C for 5 hours, and the temperature was raised to 600°C at a heating rate of 10°C / min. ℃, kept for 60min, and a sample with a diameter of about 25nm was obtained. PL from quantum-sized ZnO ( figure 2 c) The fluorescence effect of baking at 600°C can be seen. From the XRD of quantum size zinc oxide ( image 3 c) The degree of crystallization of quantum-sized zinc oxide at 600...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com