Quantum size zinc oxide and preparation method and application thereof

A zinc oxide, size technology, applied in zinc oxide/zinc hydroxide, measuring devices, instruments, etc., can solve the problems of insufficient quantum size zinc oxide preparation method, unable to prepare quantum size zinc oxide crystals, etc., to achieve structural stability , the effect of short response time and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Accurately weigh 0.2195g Zn(Ac) 2 2H 2 O and 0.06g NaOH were respectively dissolved in 20ml of absolute ethanol, under magnetic stirring at a rotational speed of 200rpm, slowly added the prepared NaOH-ethanol solution into the above Zn salt solution, so that the pH value of the mixed solution was about 12 , continue stirring for 1h. Accurately weigh 0.09 g of oleic acid, add it into the above reaction solution, and stir magnetically for 1 h. The obtained white jelly liquid was centrifuged at a speed of 3000r / s, and washed 2 to 3 times with absolute ethanol, and the white jelly obtained by centrifugation was dried at 50°C for 5 hours, and the temperature was raised to 200°C at a heating rate of 10°C / min. ℃, kept for 60 minutes, to obtain zinc oxide powder with quantum size.

[0024] According to the above experiment, except that oleic acid is not added, the prepared zinc oxide is very easy to agglomerate, and the particle size increases significantly.

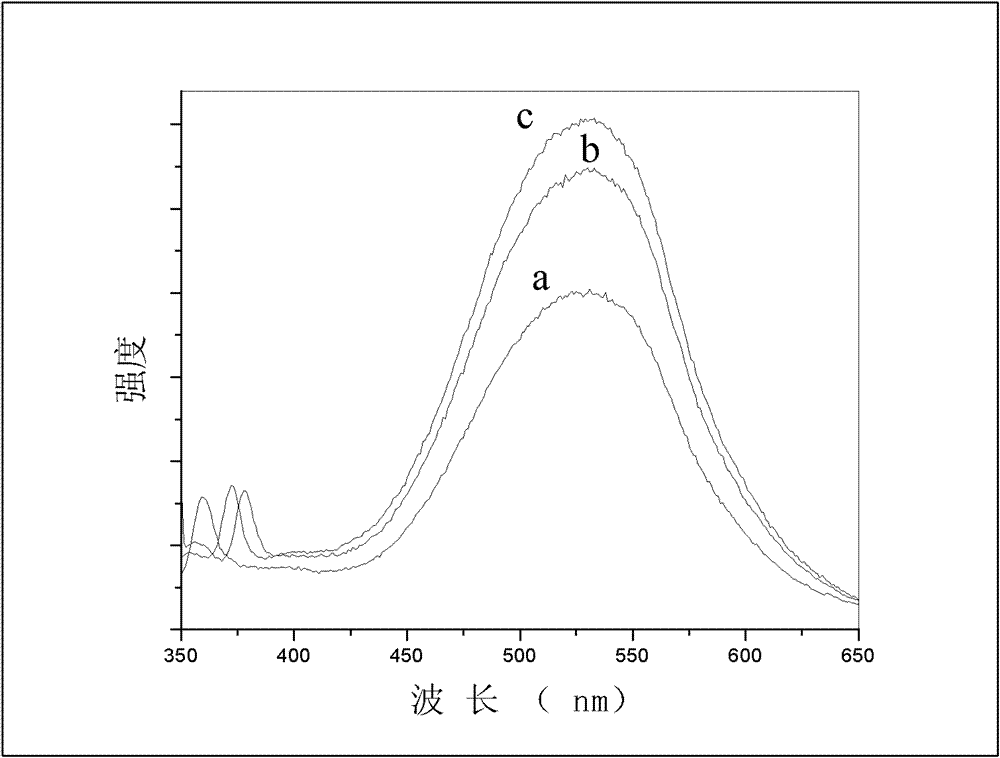

[0025] The zi...

Embodiment 2

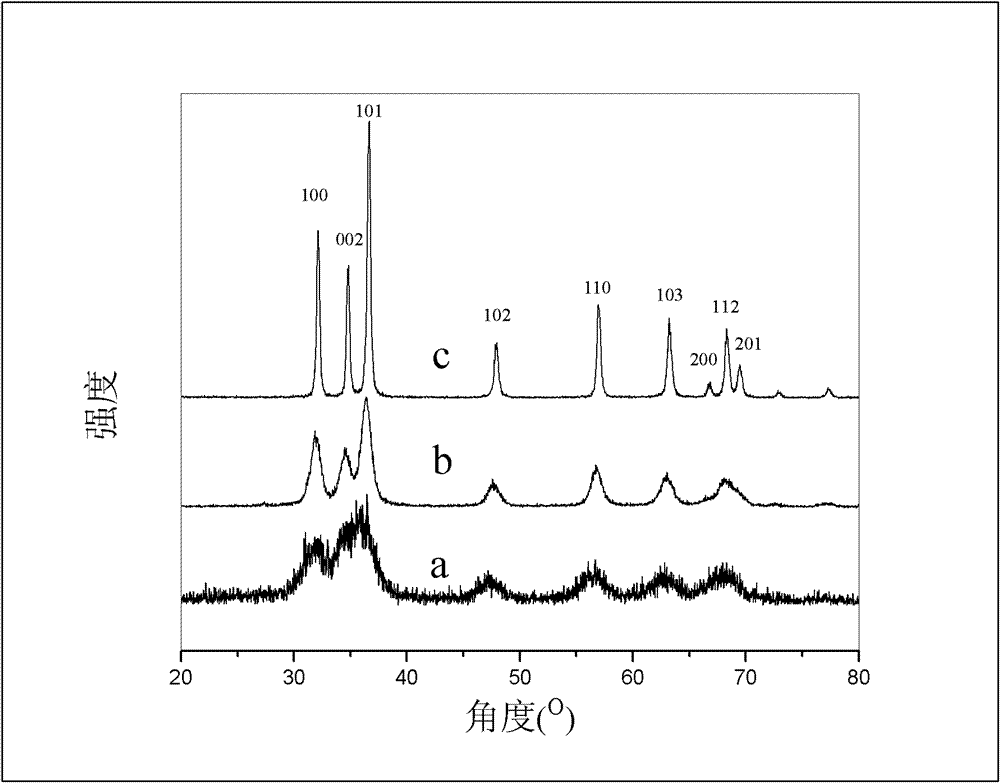

[0028] Accurately weigh 0.1785g Zn(NO 3 ) 2 ·6H 2 O and 0.12g NaOH were respectively dissolved in 20ml of absolute ethanol, under magnetic stirring at a rotational speed of 200rpm, slowly added the prepared NaOH-ethanol solution into the above Zn salt solution, so that the pH value of the mixed solution was about 12 , continue stirring for 1h. Accurately weigh 0.09 g of oleic acid and add it to the above reaction solution, and magnetically stir for 1 h. The obtained white jelly liquid was centrifuged at a speed of 3000r / s, and washed 2 to 3 times with absolute ethanol, and the white jelly obtained by centrifugation was dried at 50°C for 5 hours, and the temperature was raised to 400°C at a heating rate of 10°C / min. ℃ and kept for 60 min, a sample with a diameter of about 7 nm was obtained. PL from quantum-sized ZnO ( figure 2 b) The fluorescence effect of baking at 400°C can be seen. From the XRD of quantum size zinc oxide ( image 3 b) The degree of crystallization of...

Embodiment 3

[0030] Confirm that 0.191g ZnCl and 0.09g NaOH are dissolved in 20ml absolute ethanol respectively, and under magnetic stirring at 200rpm, the NaOH-ethanol solution prepared is slowly added dropwise to the above-mentioned Zn salt solution to make the mixed solution The pH value is about 12, continue to stir for 1h. Accurately weigh 0.09 g of oleic acid and add it to the above reaction solution, and magnetically stir for 1 h. The obtained white jelly liquid was centrifuged at a speed of 3000r / s, and washed 2 to 3 times with absolute ethanol, and the white jelly obtained by centrifugation was dried at 50°C for 5 hours, and the temperature was raised to 600°C at a heating rate of 10°C / min. ℃, kept for 60min, and a sample with a diameter of about 25nm was obtained. PL from quantum-sized ZnO ( figure 2 c) The fluorescent effect of baking at 600°C can be seen. From the XRD of quantum size ZnO( image 3 c) The degree of crystallization of quantum-sized zinc oxide at 600°C can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com