Light-load ultra-thin fork

An ultra-thin, light-load technology, applied in the direction of lifting devices, etc., can solve the problems of low efficiency, high cost, heavy weight, etc., and achieve the effect of reducing resistance and solving the requirements of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

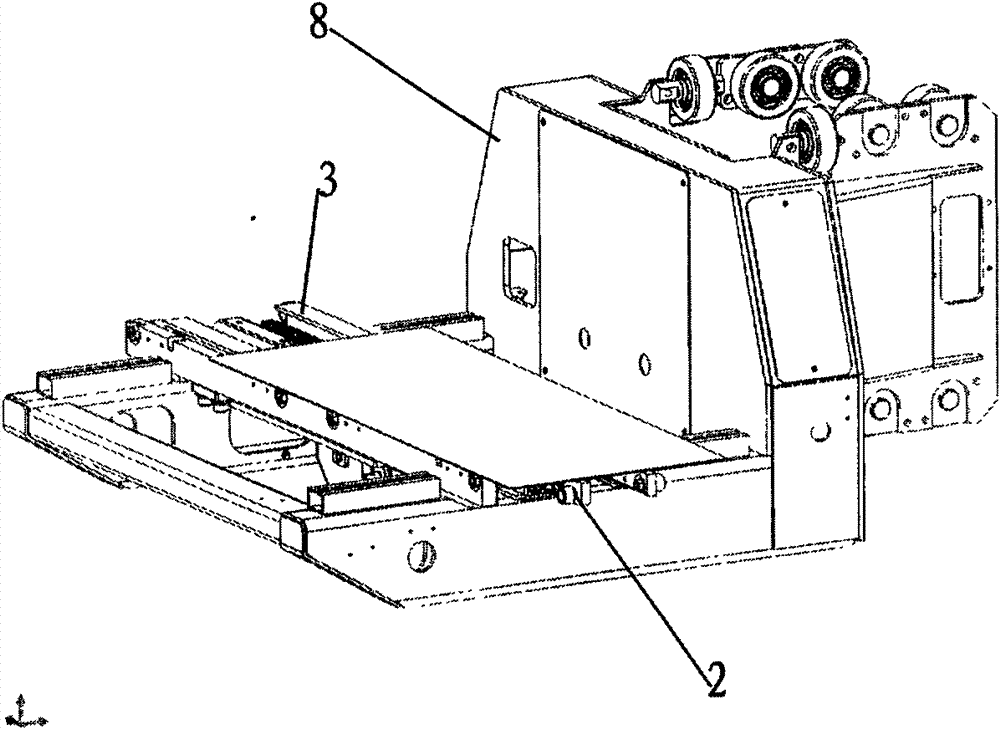

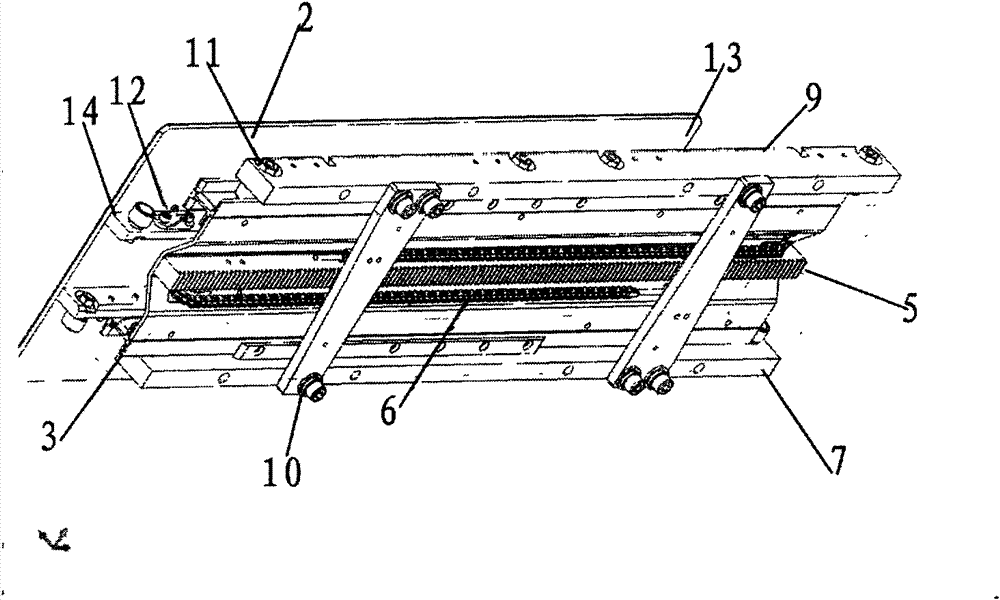

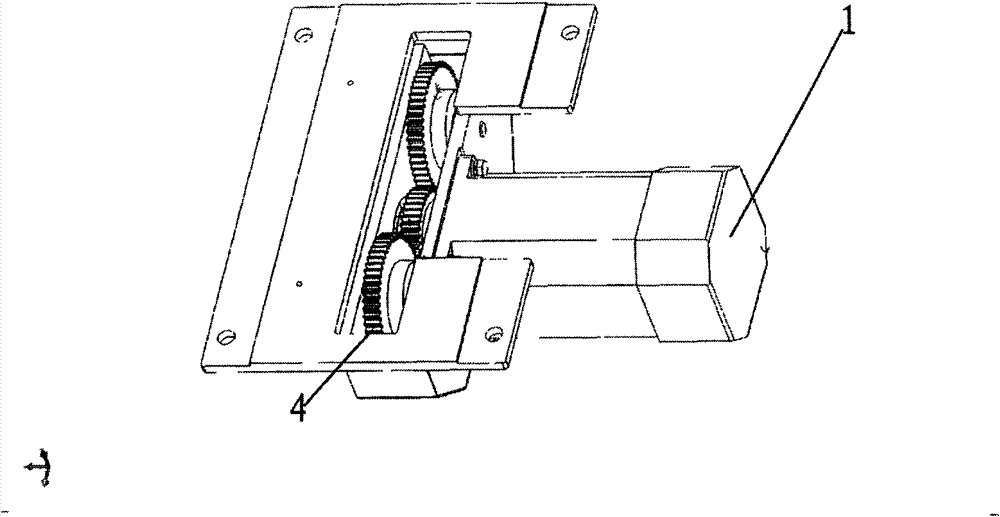

[0014] As shown in the figure, the light-duty ultra-thin cargo fork mainly includes a platform 8, an upper fork 2, a middle fork 3 and a lower fork 7. The upper fork 2, middle fork 3 and lower fork 7 together form a cargo transportation Platform, it is installed on the working platform of bench 8, and motor 1 is installed on the bench 8 again, a gear 4 is respectively established on the left and right sides of motor 1, and the gear on the motor 1 coincides with the gear 4 on the left and right sides of it, and the motor The rotation of 1 drives the rotation of the left and right gears 4. The lower fork 7 is composed of two sleepers 9 and two bottom plates 10 in the shape of a "well", and the inner sides of the two sleepers 9 are provided with 4 guide rails 11 and 4 side rails. To the wheel 12, both sides of the middle fork 3 are in the shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com