A hollow buffer structure for artificial prosthesis

A buffer structure, artificial prosthesis technology, applied in the field of artificial prosthesis, can solve the problems of strength reduction, prosthesis structure rigidity and strength contradiction, etc., to achieve the effect of improving the degree of mechanical stimulation, avoiding reconstruction and loss, and reducing the strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

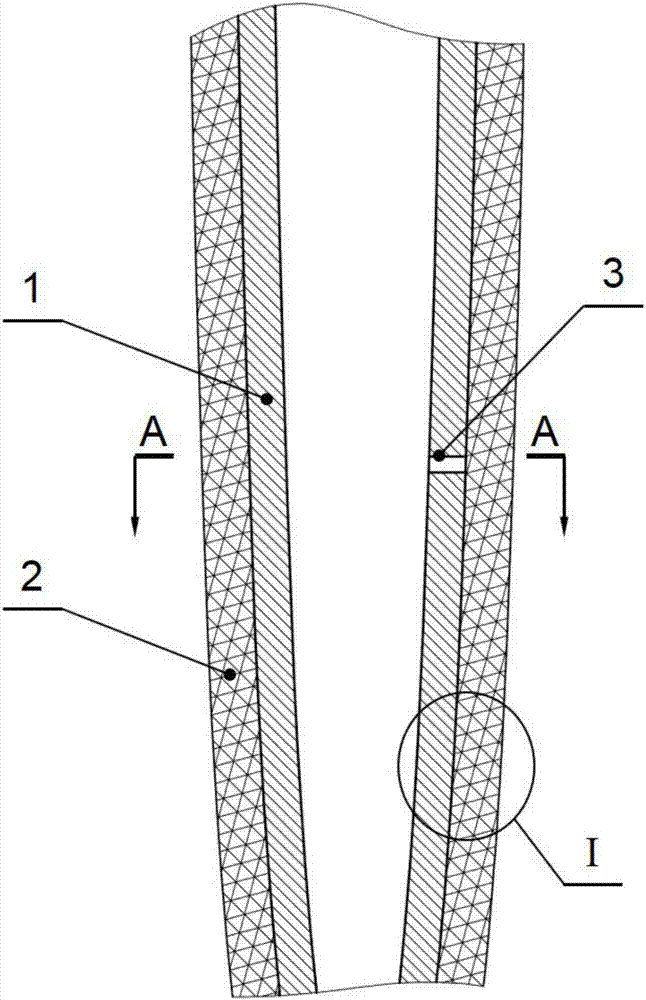

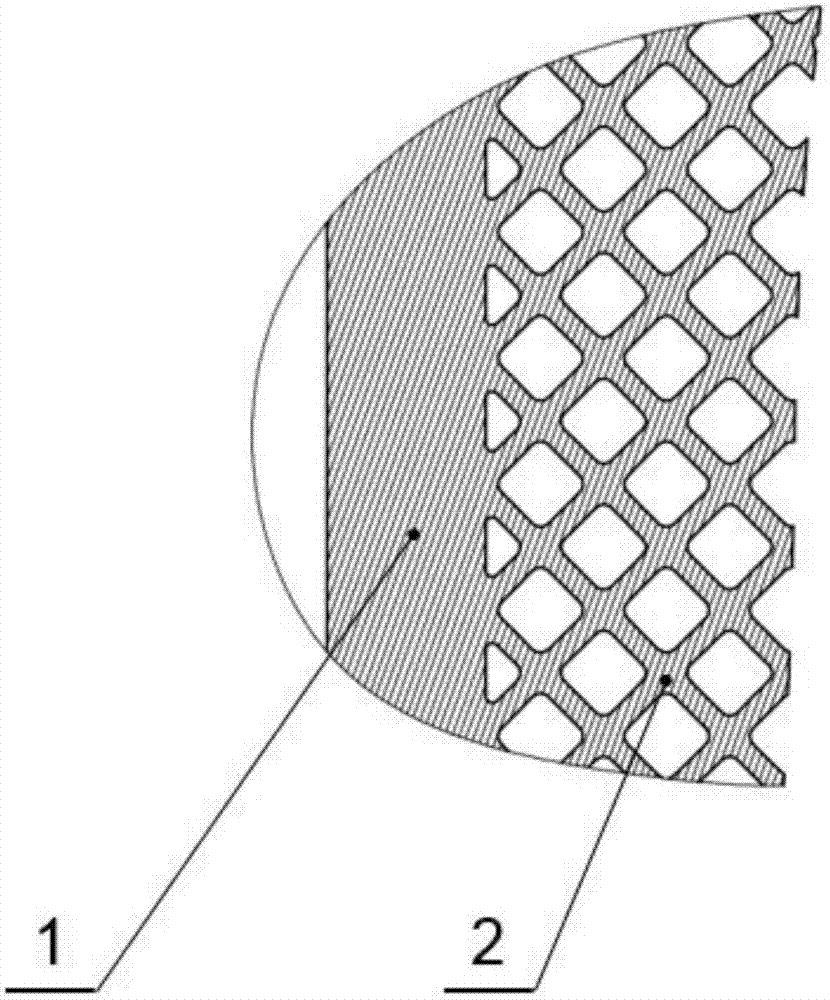

[0035] Embodiment 1, artificial hip joint femoral handle with hollow buffer structure: as Figure 4 with Figure 5 As shown, the artificial hip joint femoral stem mainly includes a neck solid part 4 and a hollow buffer part 5 , wherein the hollow buffer part 5 includes a closed thin-walled part 1 and a buffer structure 2 . The closed thin-walled part 1 is a closed hollow structure, which is located inside the femoral stem of the artificial hip joint and is wrapped by the buffer structure 2; the buffer structure 2 is composed of a three-dimensional grid-like porous structure, which is filled outside the closed thin-walled part 1. The artificial hip joint within the outer contour of the femoral stem. There is a small through hole 3 on the top of the closed thin-walled part 1, the diameter of which is 1mm, and the small through-hole 3 is connected with the positioning hole of the femoral stem of the artificial hip joint to discharge the residual powder inside the closed thin-wal...

Embodiment 2

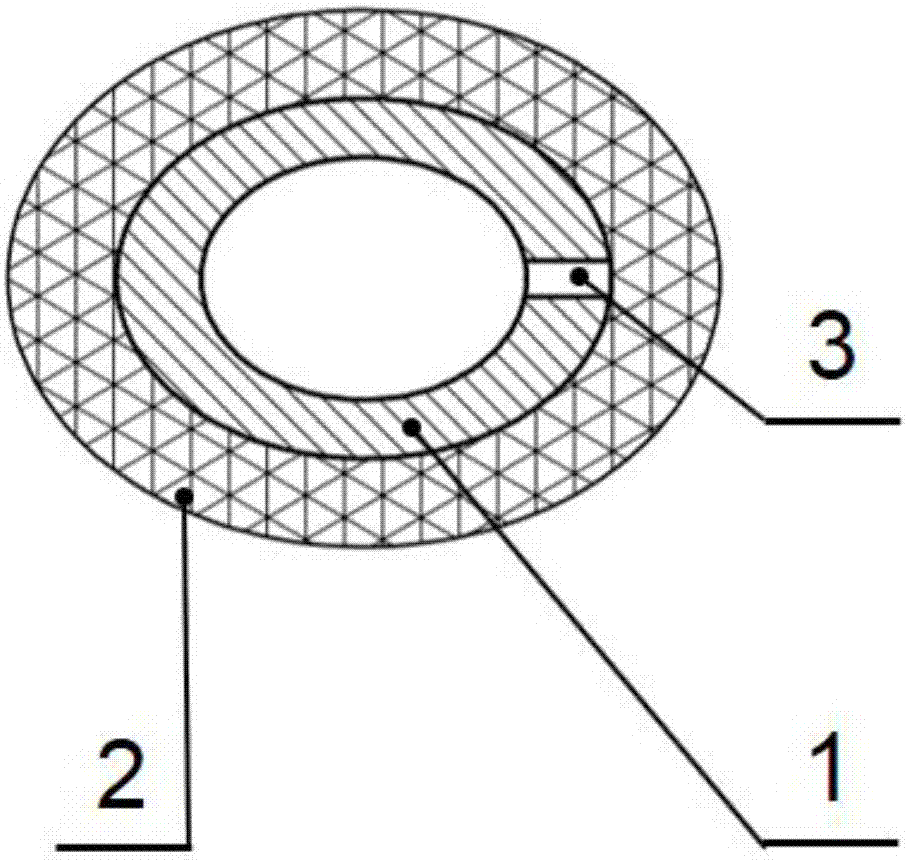

[0041] Embodiment 2: tibial tray with hollow cushioning structure: as Image 6 with Figure 7 As shown, the tibial tray includes a tray solid part 6 and a hollow buffer part 5 , wherein the hollow buffer part 5 includes a closed thin-walled part 1 and a buffer structure 2 . The closed thin-walled part 1 is a closed hollow structure, which is located at the lower part of the tibial tray and wrapped by the buffer structure 2; the buffer structure 2 is composed of a three-dimensional grid-like porous structure, which is filled outside the closed thin-walled part 1 and inside the outer contour of the tibial tray . There is a small through hole 3 on the top of the closed thin-walled part 1, the diameter of which is 1mm, and the small through hole 3 is located at the center of the bottom of the tibial tray to discharge the residual powder inside the closed thin-walled part 1.

[0042] The shape of the closed thin-walled part 1 of the tibial tray is a body of revolution developed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com