Filter material with composite ultrafine chopped fibers on surface

A technology of fine short fiber and filter material, which is applied in the field of surface-use composite ultrafine short fiber filter material, can solve the problems of high wind speed for dust removal and filtration, large initial resistance of dust removal and filtration, and easy damage to film micropores, etc., to achieve Excellent mechanical properties, overcoming large initial resistance, and prolonged use of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

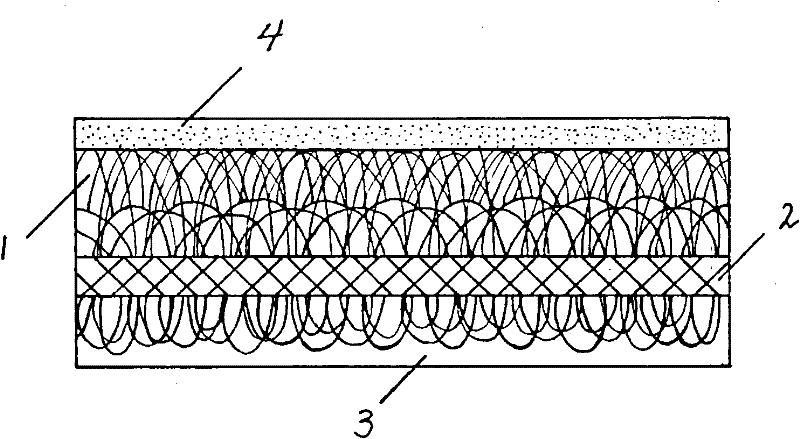

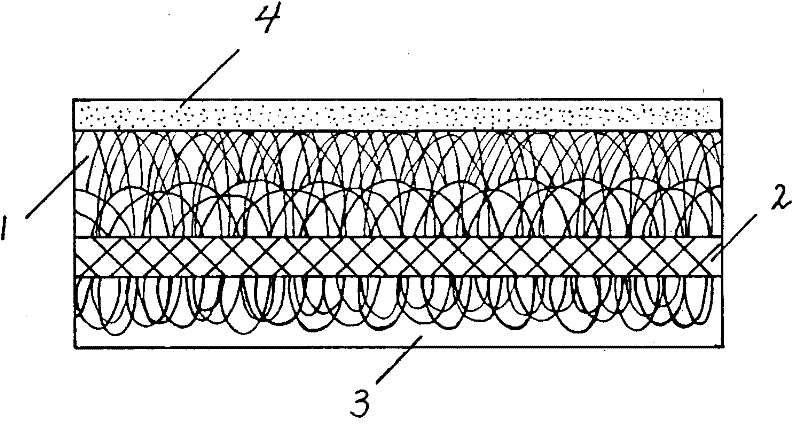

[0012] The filter material of composite ultrafine short fibers for surface of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] see figure 1 , The filter material of composite ultrafine short fibers for the surface of the invention comprises a surface layer 1, a base cloth 2 and a bottom layer 3.

[0014] The bottom layer 3 is formed by needling glass fibers, polyphenylene sulfide fibers and polytetrafluoroethylene fibers.

[0015] The surface layer 1 is formed by needle-punching polyphenylene sulfide short fibers and polytetrafluoroethylene short fibers.

[0016] The end surface of the surface layer 1 is melt-blown or hot-pressed with a composite layer 4 formed of glass ultra-fine short fibers, polyphenylene sulfide ultra-fine short fibers and polytetrafluoroethylene ultra-fine short fibers. The fineness of the glass ultrafine short fibers in layer 4 is 0.3-1.0dtex, the fineness of the polyphenylene sulfi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com