Cooling device in t-bar hot-rolling line, and t-bar manufacturing facility and manufacturing method

A technology for manufacturing equipment and T-shaped steel, which is applied to workpiece cooling devices, manufacturing tools, metal rolling, etc., can solve problems such as hindering T-shaped steel, unable to solve cooling bending, etc., and achieve the effect of reducing equipment cost and simplifying equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

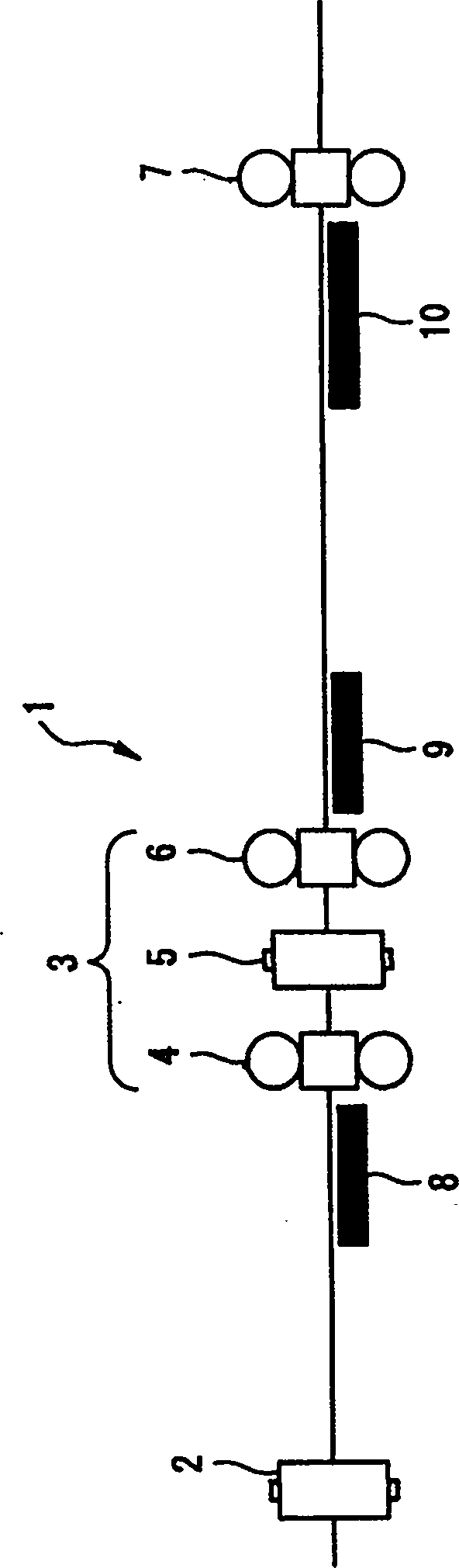

[0097] As a first example, using figure 1 The illustrated T-shaped steel manufacturing facility 1 rolls a T-shaped steel with target dimensions of web height 300 mm, flange width 100 mm, web thickness 9 mm, and flange thickness 16 mm from a steel ingot having a rectangular cross-section with a thickness of 250 mm and a width of 310 mm.

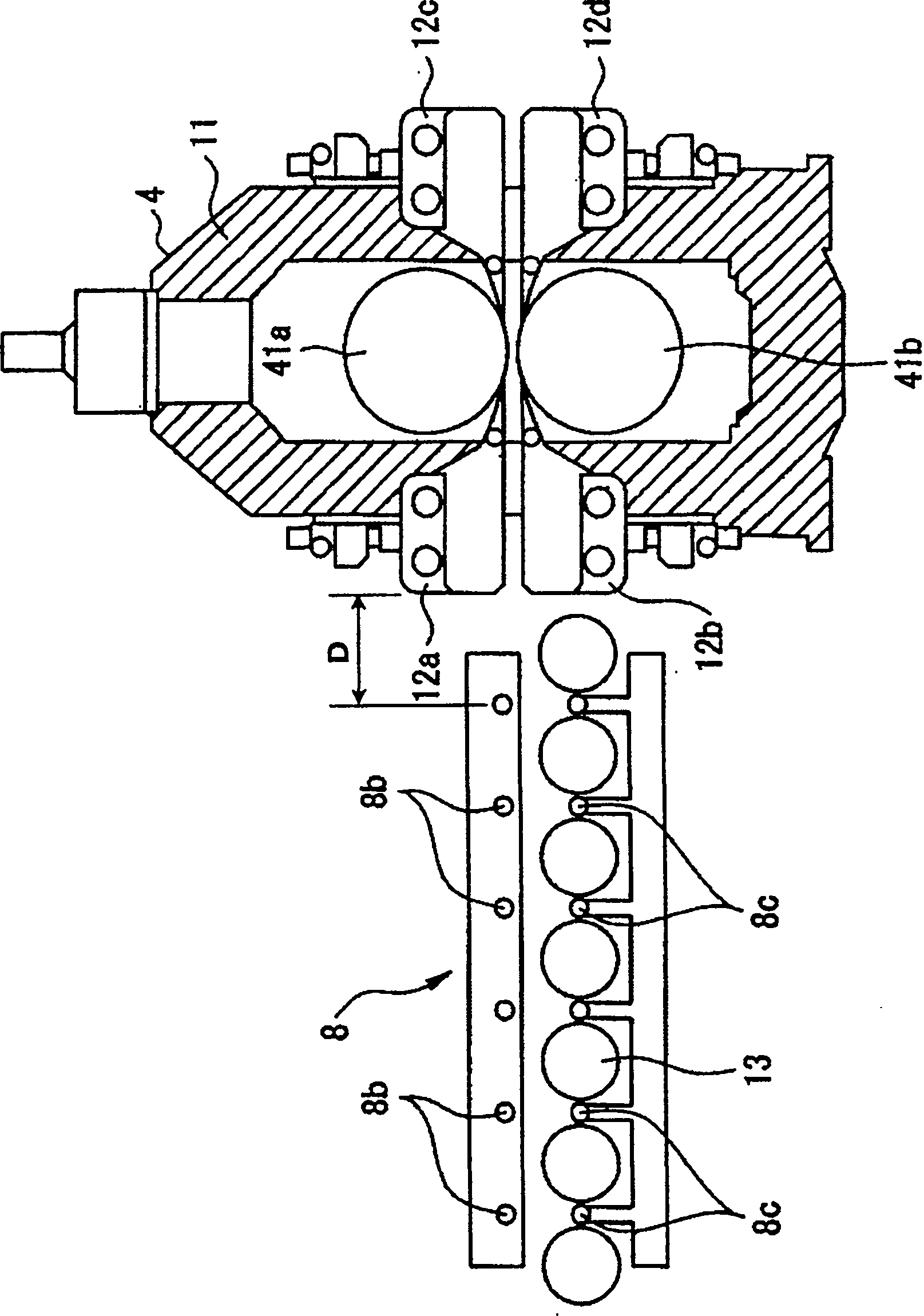

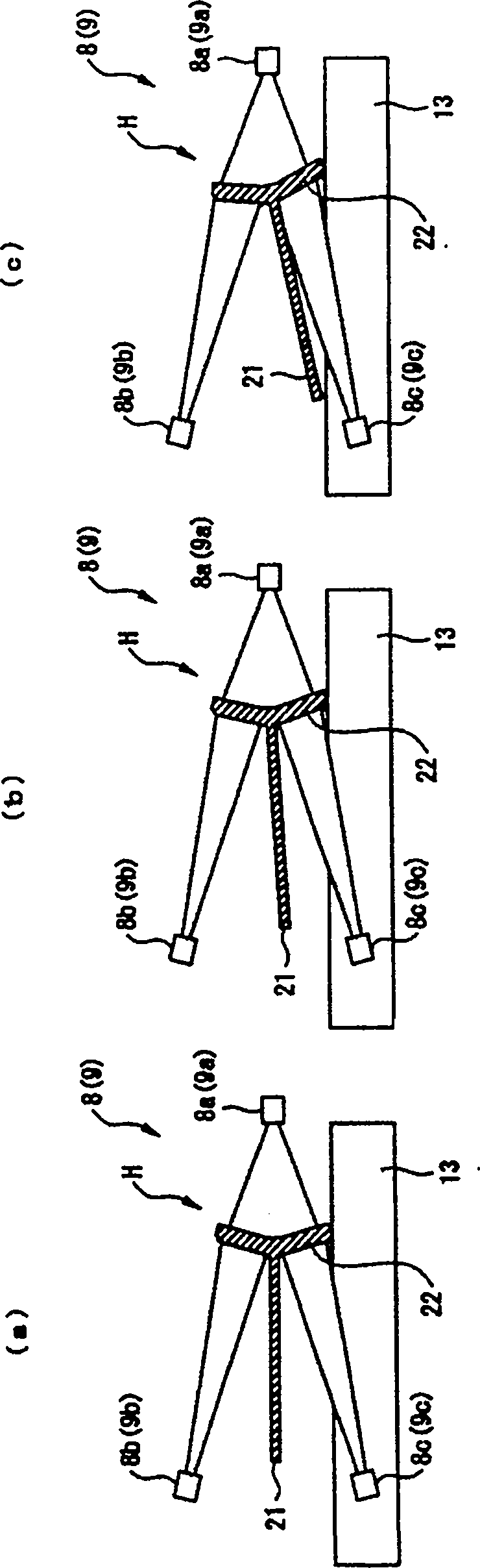

[0098] Such as figure 1 As shown, cooling devices 8, 9, 10 are provided before and after the intermediate rolling group 3 and in front of the finishing mill (universal finishing mill) 7. These cooling devices are arranged close to the outside of the rolling mill main body, and the distance D between the rolling mill main body and the cooling devices is 3 m. The spraying direction of the water-cooling nozzles (8a, 9a, etc.) on the outer surface of the flange is 10° downward relative to the horizontal direction. In addition, it is configured to be mounted on a side guide that guides the material H to be rolled to the side of the flange 22 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com