Transient temperature distribution sensor in fuel cell

A fuel cell and internal temperature technology, which is applied to fuel cell components, fuel cell additives, fuel cell heat exchange, etc., can solve the problem of not reflecting the temperature distribution of fuel cells, not meeting the requirements of real-time temperature measurement, and the scope of use Limitation and other issues, to achieve the effect of simple structure, convenient and quick disassembly, and small heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

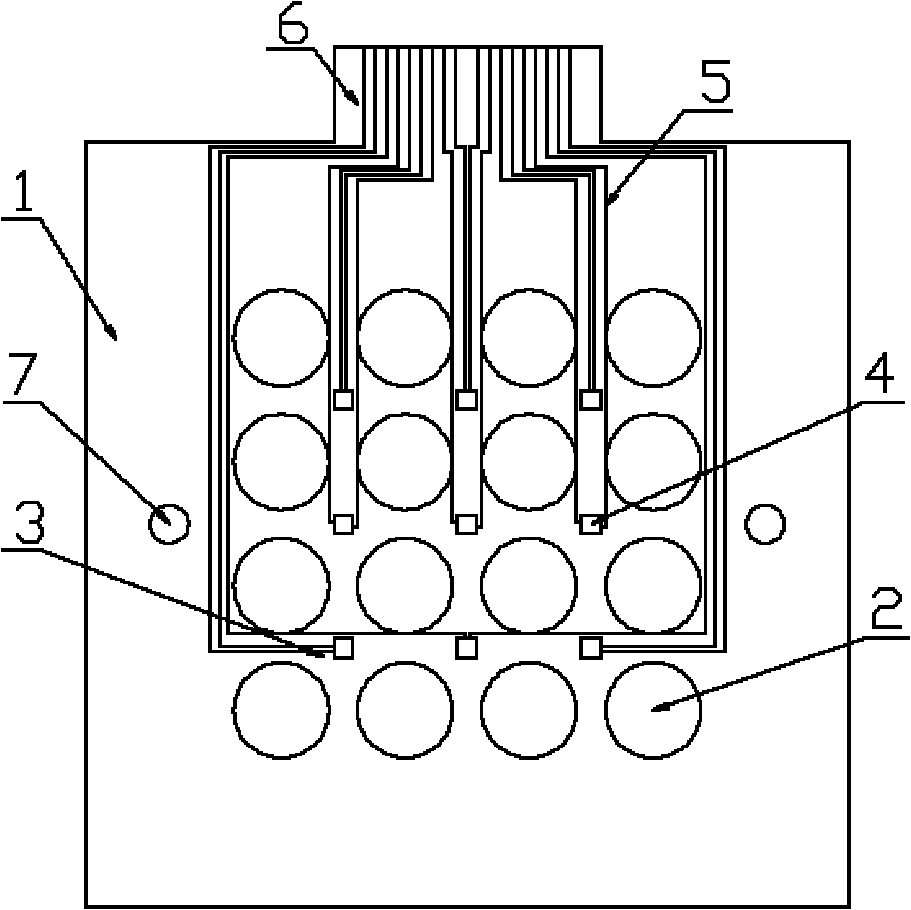

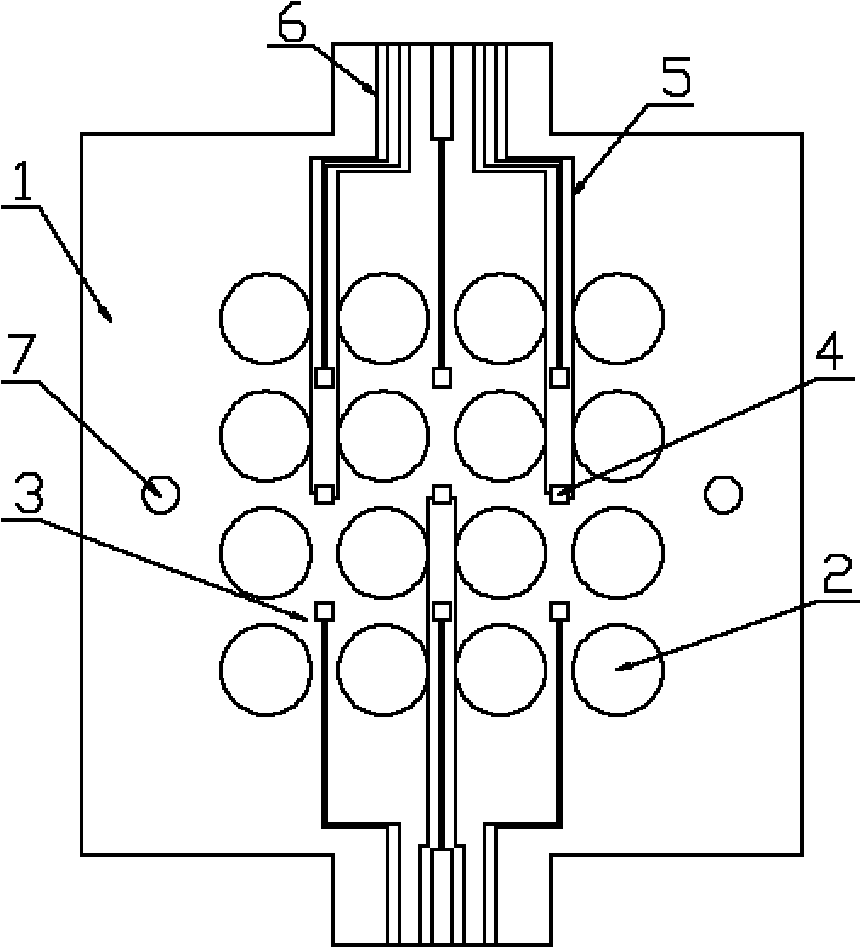

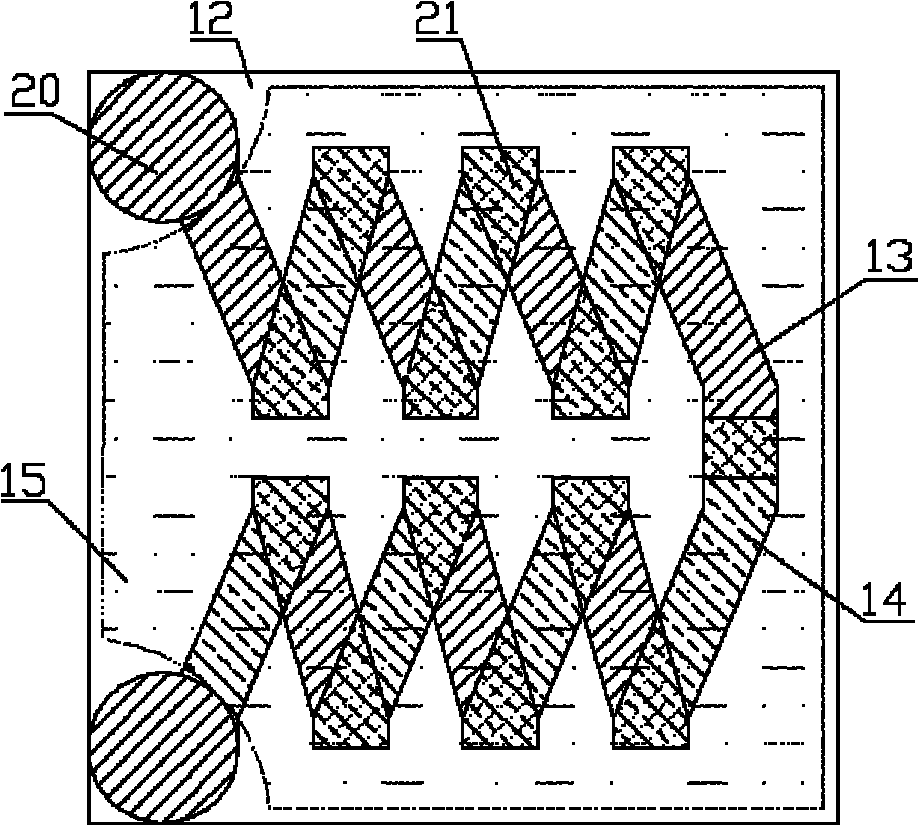

[0030] Accompanying drawing is the specific embodiment of the present invention;

[0031] Below in conjunction with accompanying drawing, content of the present invention is described in further detail:

[0032] refer to figure 1 , figure 2 , image 3 As shown, the present invention includes that some thin-film thermocouples 4 are coated on the ribs 3 between two adjacent flow channels 2 on the graphite flow field plate 1 in the fuel cell, and the lead-out wires 5 of the thin-film thermocouples 4 extend to the graphite flow field The edge of the board 1 is provided with a standard wiring port 6 connected to an external circuit at the end of the lead wire 5 . The thin-film thermocouple 4 and its lead wire 5 of the present invention are all made on the graphite flow field plate 1, and the lead wire 5 extends to the end of the graphite flow field plate 1 with a width of 0.05-0.1 mm and a thickness of no more than 0.2 μm. Through the standard data interface 6 connected to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com