Garbage incinerator without dioxin emission

A technology for waste incinerators and furnace bodies, which is applied in incinerators, combustion methods, combustion types, etc., can solve the problems of unavailability of water vapor, air pollution, and labor-intensive feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

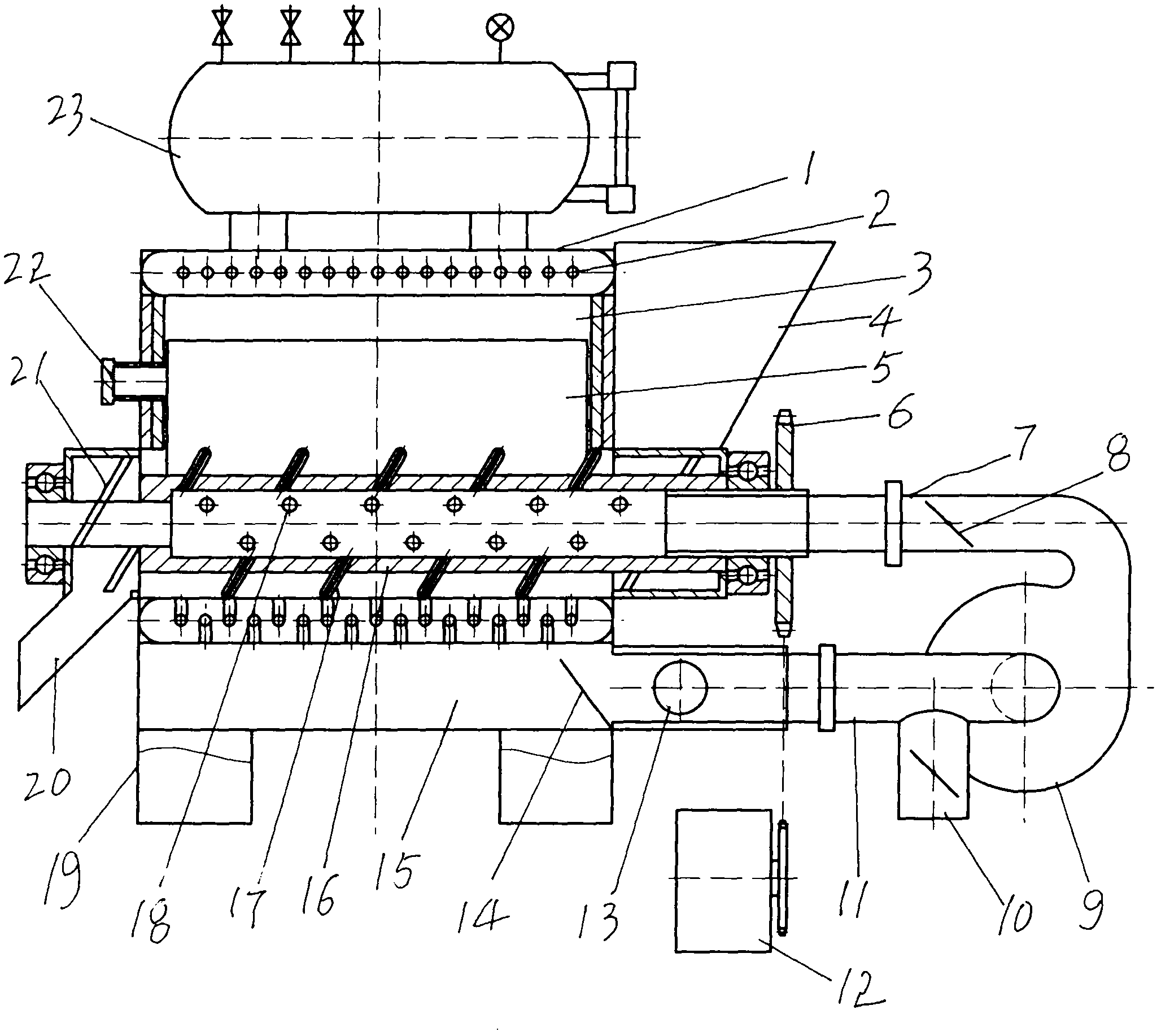

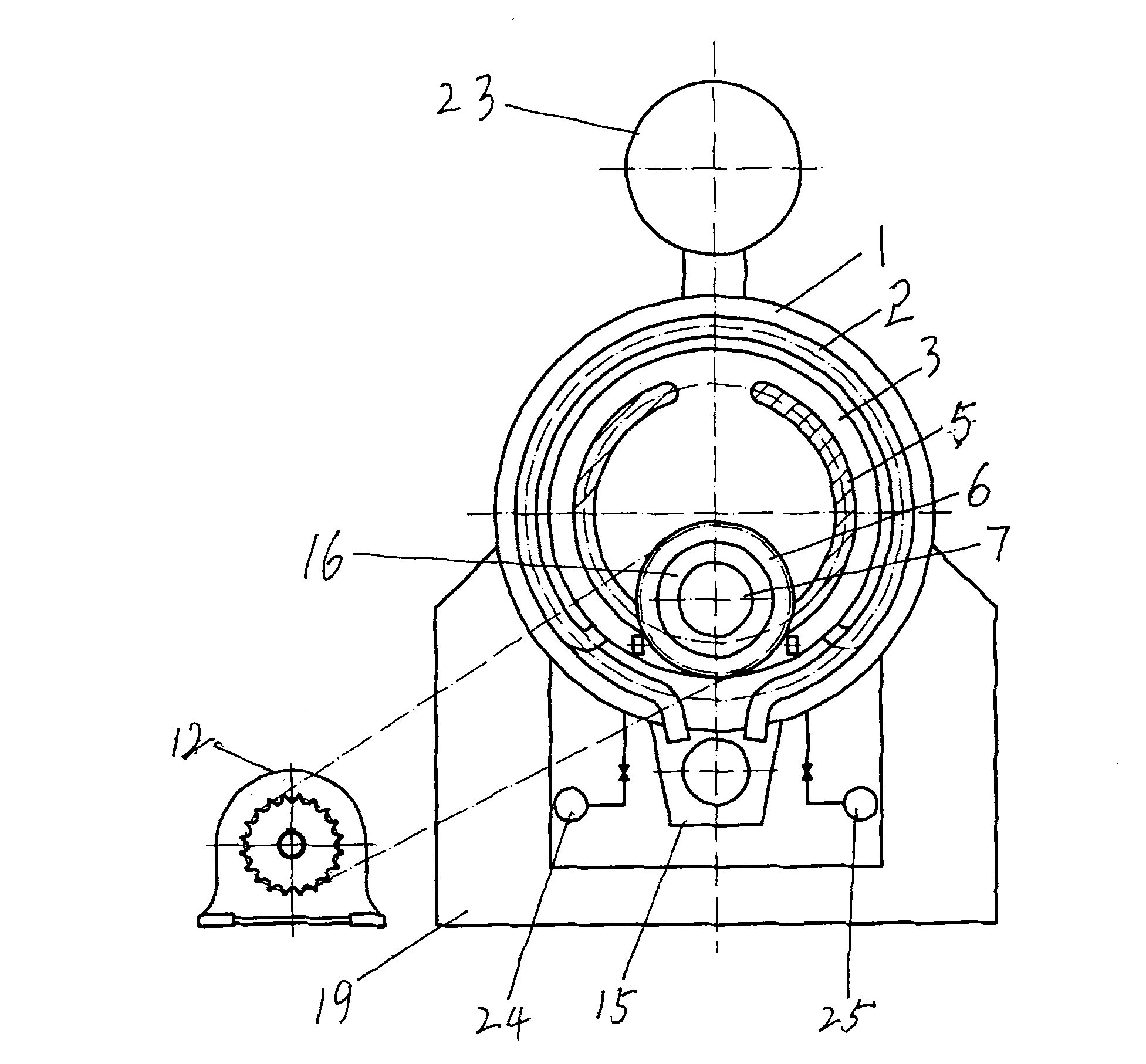

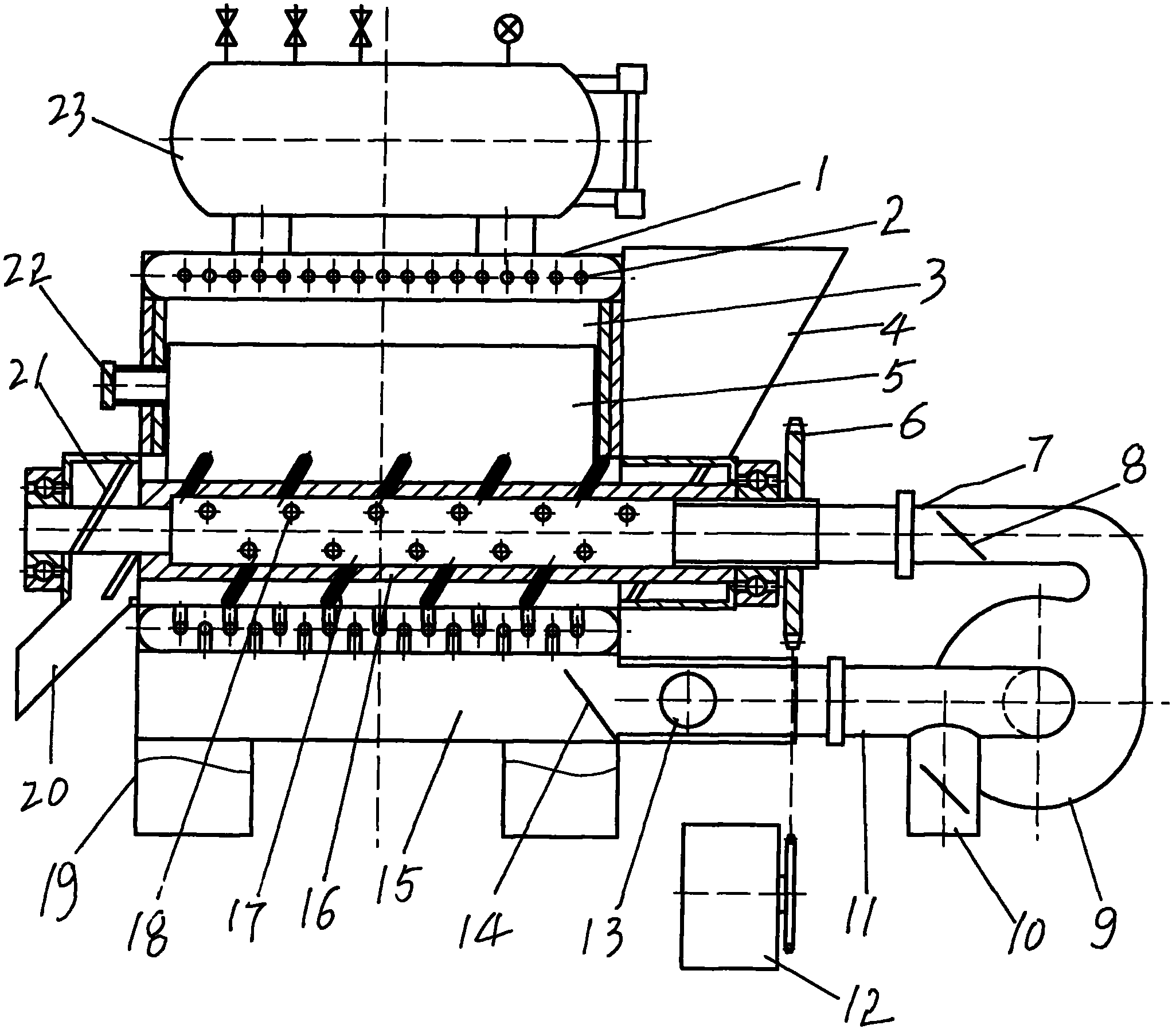

[0007] Describe embodiment in detail in conjunction with accompanying drawing, the present invention is that an annular hot water jacket 1 is installed in the circumferential wall of a horizontal furnace body, and support 19 is installed on the furnace wall on both sides of the bottom of the furnace body, on both sides An ash hopper 15 is installed at the lower part of the furnace body between the supports, a water inlet 25 and a sewage outlet 24 are connected to the hot water jacket at the bottom of the furnace body, and a high-pressure water tank connected to the hot water jacket is installed on the top of the furnace body through a connecting pipe. Steam drum 23, in the combustion chamber in the middle of the furnace body, two arc-shaped fire walls 5 are arranged longitudinally on both sides with the center of the hot water jacket. There is a tempering port in the middle of the top. On the upper surface of the bottom of the hot water jacket between the bottoms of the two fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com