Late poured band type assembled pipe jacking working open caisson

A technology for working wells and pipe jacking, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of traffic flow in the construction section, affect the normal life of residents, and long construction period, so as to reduce pollution and improve the normal life of residents The effect of reducing the construction period and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

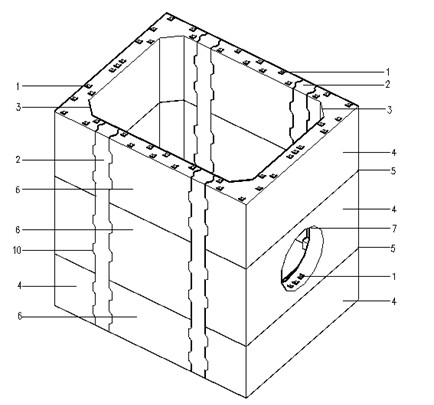

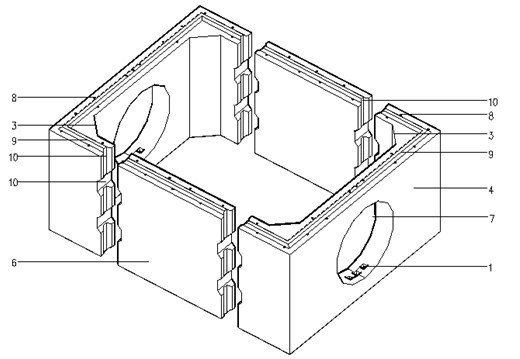

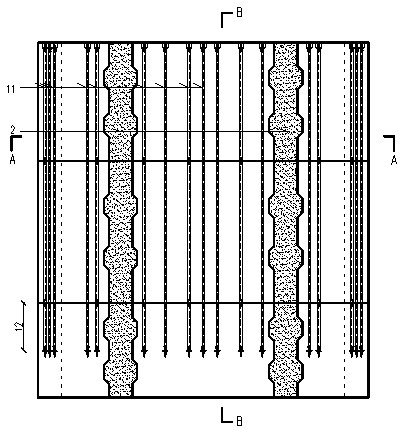

[0024] The invention is a prefabricated and assembled rectangular pipe-jacking working well. The working well is divided into three sections vertically, and the length of each section is between 2m and 3m. Each prefabricated well slice is vertically connected by prestressed steel bars 11 . Finished rolled rebar is used as prestressed reinforcement. Each transverse section is composed of two U-shaped wells 4 (B prefabricated) and two inline wells 6 (A prefabricated). Among them, the U-shaped well slice 4 adopts the structure of adding axils 3 . The well slices are connected by the post-casting tape 2 in the transverse direction. The U-shaped well slice (short side direction) is the direction of pipe jacking. In order to increase the cohesion with the post-casting tape 2, the side of the prefabricated well sheet is designed in the form of concave and convex tooth grooves 10.

[0025] The prestressed steel bar 11 is located in the reserved channel 8 of the prefabricated well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com