Production method for bactericidal packing paper

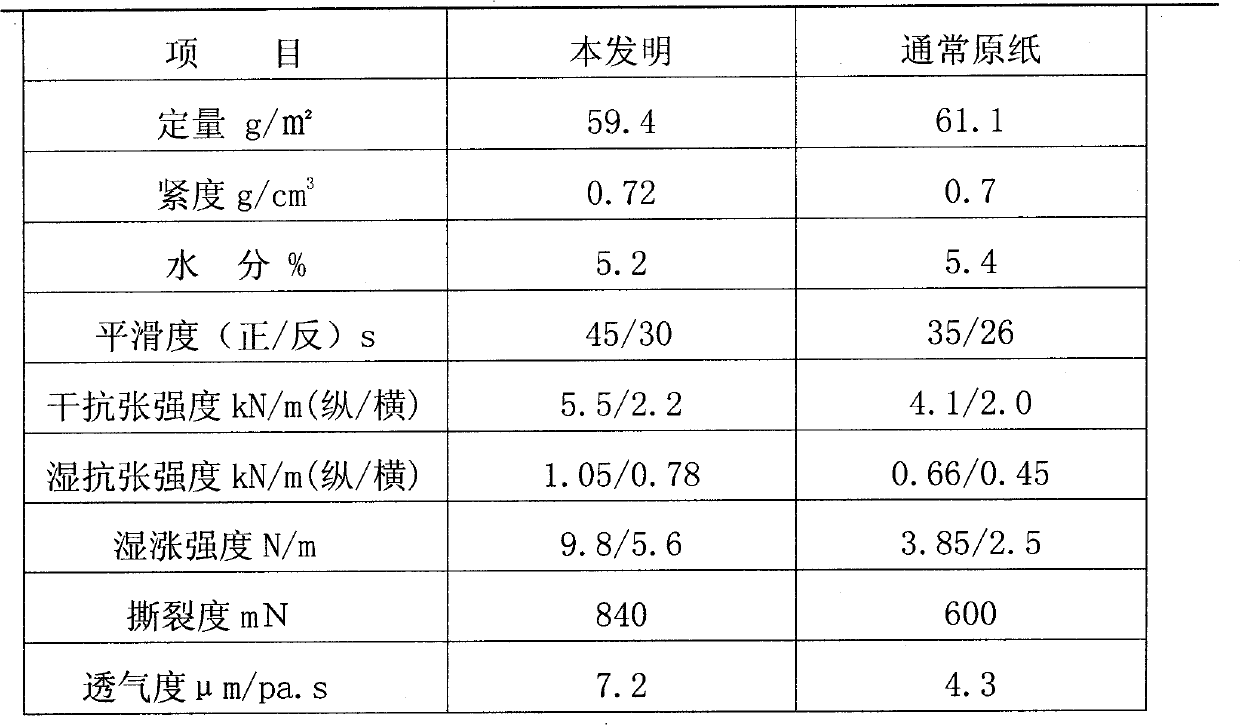

A production method and packaging paper technology, applied in paper, papermaking, paper coating, etc., can solve the problems of incomplete sterilization, easy damage, and difficulty in reaching, so as to improve surface strength and mechanical strength, and ensure fiber length and strength , good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] ①Preparation process of sizing solution in slurry: add 600kg of clean water and 50kg of YF-921 cationic starch into the glue pot, stir evenly, slowly heat up to 95℃, keep warm for 20 minutes, add water to 1M 3 Mark the scale line, stir evenly to prepare the sizing liquid in the slurry for later use.

[0028] ②Surface sizing solution preparation process: add 400kg of clear water, 25kg of polyvinyl alcohol soaked for 4 hours and 50kg of YF-412 tapioca starch into the glue pot, stir evenly and slowly heat up to 95°C, keep the temperature for 20 minutes, add water to 1.5M 3 Scale line, stir evenly, filter into a storage bucket, and keep the temperature at 65-68°C for later use.

[0029] 3. Preparation of carboxymethyl cellulose solution: add 400kg of clean water to the glue pot, heat it to 70°C, start the stirrer and slowly and evenly sprinkle 75kg of LC-10 carboxymethylcellulose, slowly heat up to 95°C, wait for After the powder is completely dissolved, add water to 1.5M ...

Embodiment 2

[0036] ①Preparation process of sizing solution in slurry: add 600kg of clean water and 50kg of YF-921 cationic starch into the glue pot, stir evenly, slowly heat up to 95℃, keep warm for 20 minutes, add water to 1M 3 Mark the scale line, stir evenly to prepare the sizing liquid in the slurry for later use.

[0037] ②Surface sizing solution preparation process: add 400kg of clear water, 20kg of polyvinyl alcohol soaked for 4 hours and 40kg of YF-412 tapioca starch into the glue pot, stir evenly and slowly heat up to 95°C, keep the temperature for 20 minutes, add water to 1.5M 3 Scale line, stir evenly, filter into a storage bucket, and keep the temperature at 65-68°C for later use.

[0038] 3. Preparation of carboxymethyl cellulose solution: add 400kg of clean water to the glue pot, heat it to 70°C, start the stirrer and slowly and evenly sprinkle 75kg of LC-10 carboxymethylcellulose, slowly heat up to 95°C, wait for After the powder is completely dissolved, add water to 1.5M ...

Embodiment 3

[0045] ①Preparation process of sizing solution in slurry: add 600kg of clean water and 50kg of YF-921 cationic starch into the glue pot, stir evenly, slowly heat up to 95℃, keep warm for 20 minutes, add water to 1M 3 Mark the scale line, stir evenly to prepare the sizing liquid in the slurry for later use.

[0046] ②Surface sizing solution preparation process: add 400kg of clean water, 22.5kg of polyvinyl alcohol soaked for 4 hours and 45kg of YF-412 tapioca starch into the glue pot, stir evenly and slowly heat up to 95°C, keep the temperature for 20 minutes, add water to 1.5 M 3 Scale line, stir evenly, filter into a storage bucket, and keep the temperature at 65-68°C for later use.

[0047]3. Preparation of carboxymethyl cellulose solution: add 400kg of clean water to the glue pot, heat it to 70°C, start the stirrer and slowly and evenly sprinkle 75kg of LC-10 carboxymethylcellulose, slowly heat up to 95°C, wait for After the powder is completely dissolved, add water to 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com