Replacement cooking pulping method

A replacement cooking and pulping technology, which is used in the regeneration of pulping liquid, pulping of cellulose raw materials, textiles and papermaking, etc., can solve the problems of restricting the number of cooking pots, high investment cost, affecting production, etc. The effect of shortening, less dosage, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

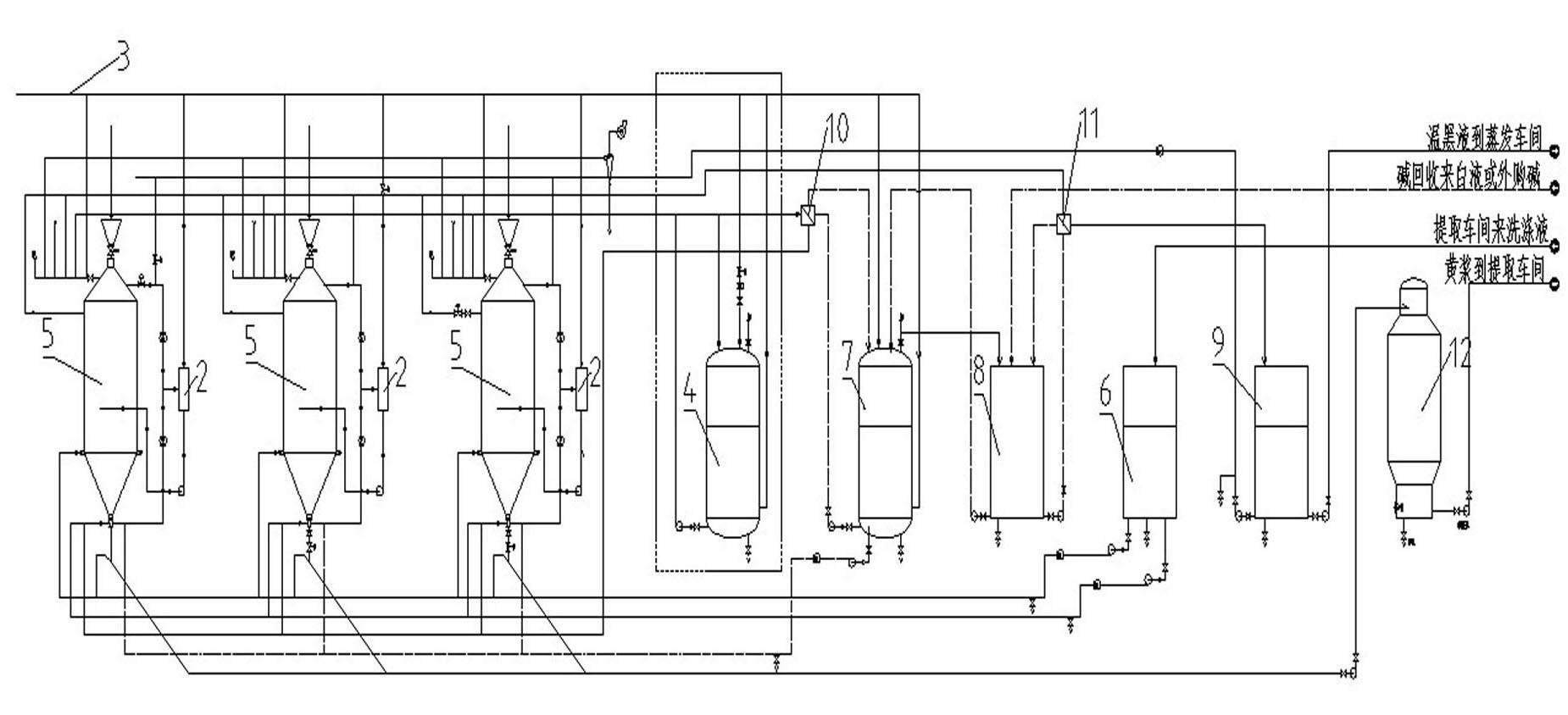

[0032] Embodiment 1: a kind of displacement cooking pulping method, adopts a cooking pot, comprises the following steps:

[0033] 1. First steam a pot of material with the traditional steaming method, and replace the hot black liquor to the hot black liquor tank before discharging.

[0034] 2. Pot loading: put the raw materials into the cooking pot, and add warm black liquor at the same time;

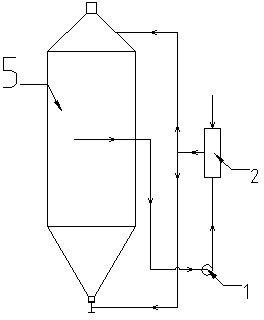

[0035] 3. Warm charging: close the lid valve, pump the black liquor in the warm black liquor tank from the bottom of the cooking pot, the black liquor will be filtered from the top through the grate in the pot, and then discharged from the top of the pot, and then flow back to the warm black liquor tank for continuous circulation Stop the cycle until the temperature difference between the two sides is 0-10°C.

[0036] 4. Substitution and temperature rise, the hot black liquor from the hot black liquor tank is sent to the bottom of the cooking pot after being exchanged by the first heat...

Embodiment 2

[0044] Embodiment 2: a kind of displacement cooking pulping method, adopts 4 cooking pots, comprises the following steps:

[0045] First cook one or two cooking pots with the traditional cooking method. The cooking time should be staggered to facilitate operation. When the H factor of one of the cooking pots reaches 800-1200. Assuming it is the second cooking pot and there is black liquor in the warm black liquor tank,

[0046] Pot loading: put the raw materials into the first cooking pot, and add warm black liquor at the same time;

[0047] Warm charging: close the lid valve, pump black liquor into the warm black liquor tank from the bottom of the cooking pot, filter it through the grate in the pot from the top, discharge it from the top of the pot and return it to the warm black liquor tank, and continue to circulate until the temperature difference between the two sides is 0-10 °C to stop the cycle. Close the inlet and outlet valves;

[0048]The temperature is raised by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com