Method for producing phycite by using corn meal

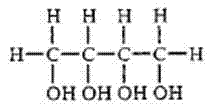

A technology of erythritol and corn flour, which is applied in the field of fermentation and production of erythritol, can solve the problems that waste bacteria cannot be recycled, the pressure of environmental protection is increased, and the resource utilization efficiency is not high, so as to avoid repeated wastewater treatment and energy consumption, improve efficiency, and improve the effect of bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153] 1. Bacteria culture

[0154]Take 200g of degerminated corn flour and 2.5g of yeast cells. After mixing and extruding, add water to make the volume to 0.7L, and then put it into a 3L seed tank. The feed liquid is preheated to 50°C, stirred, and the pH value of the feed liquid is adjusted to 5.8- 6.0, add 0.09mL of high temperature resistant amylase, the addition amount is 0.6L / t starch dry base, pass steam to heat up at 100°C for liquefaction, and keep the temperature for 20min. Then cool down to 50-55°C, adjust the pH to 4.5, add 0.09mL of high-efficiency liquid saccharification enzyme or compound saccharification enzyme, add 0.6L / t starch dry base, add 0.03g of protease, stir and keep at 50-55°C for 20h, saccharification Liquid DE value 95.3%.

[0155] The saccharified feed solution was heated to 121°C for sterilization for 20min, cooled to 28-35°C, the volume of the feed solution was 0.8L, the pH was adjusted to 5.5-6.5, and cultured with Candida lipolytica CGMCC No....

Embodiment 2

[0162] 1. Bacterial culture

[0163] Take 200g of degerminated corn flour and 2.5g of yeast cells, extrude and extrude, add water to make the volume to 0.7L, put it into a 3L seed tank, warm the feed liquid to 50°C in advance, stir, and adjust the pH value of the feed liquid to 5.8- 6.0, add 0.09mL of high temperature resistant amylase, the amount of addition is 0.6L / t corn flour dry basis, pass steam to heat up at 100°C to liquefy, and keep the temperature for 20min. Then cool down to 50-55℃, adjust pH to 4.0-4.5, add 0.09ml high-efficiency liquid saccharification enzyme or compound saccharification enzyme, add 0.6L / t corn flour dry base, add protease 0.03g, stir and keep saccharification at 50-55℃ 20h, the DE value of the saccharification solution was 95.3%.

[0164] The saccharified feed solution was heated to 121°C for sterilization for 20min, cooled to 28-35°C, the volume of the feed solution was 0.8L, the pH was adjusted to 5.5-6.5, and the cultured with Candida lipolyt...

Embodiment 3

[0171] 1. Bacteria culture

[0172] Take 200g of degerminated corn flour, 2.5g of yeast cells, add water to make the volume to 0.7L, connect to a 3L seed tank, pre-heat the feed liquid to 50°C, stir, adjust the pH value of the feed liquid to 5.8-6.0, add high temperature resistant starch The enzyme is 0.09mL, the addition amount is 0.6L / t corn flour dry basis, the feed liquid is directly passed into the steam to heat up at 100°C to liquefy, and the temperature is kept for 20min. Then cool down to 50-55 ℃, adjust pH to 4.5, add 0.09 mL of high-efficiency liquid saccharification enzyme or complex saccharification enzyme, add 0.03 g of protease, add 0.6 L / t corn flour dry basis, stir and saccharify at 50-55 ℃ for 20 hours, The DE value of the saccharification solution reached 94.3%.

[0173] The saccharified feed solution was heated to 121°C for sterilization for 15min, cooled to 28-35°C, the volume of the feed solution was 0.8, the pH was adjusted to 5.5-6.5, and cultured with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com