Method for producing phycite by using corn meal

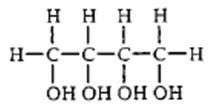

A technology of erythritol and corn flour, which is applied in the field of fermentation and production of erythritol, can solve the problems of non-recyclable waste bacteria, low resource utilization efficiency, and increased environmental protection pressure, so as to avoid repetitive waste water Effects of treatment and energy consumption, increased bioavailability, increased efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153] 1. Strain culture

[0154] Take 200g of degerminated corn flour and 2.5g of yeast cells, after mixing and extruding, add water to make up to 0.7L, put it into a 3L seed tank, raise the temperature of the feed liquid to 50°C in advance, stir, and adjust the pH value of the feed liquid to 5.8- 6.0, add 0.09mL of high-temperature-resistant amylase, the addition amount is 0.6L / t starch dry basis, heat up to 100°C for liquefaction by passing steam, and keep warm for 20min. Then lower the temperature to 50-55°C, adjust the pH to 4.5, add high-efficiency liquid glucoamylase or compound glucoamylase 0.09mL, add 0.6L / t starch dry basis, add protease 0.03g, stir at 50-55°C for 20 hours, and saccharify The liquid DE value is 95.3%.

[0155]Raise the temperature of the saccharification feed solution to 121°C for 20 minutes, then cool it down to 28-35°C, adjust the volume of the feed solution to 0.8L, adjust the pH to 5.5-6.5, insert Candida lipolytica CGMCC No.1431 strain for cult...

Embodiment 2

[0162] 1. Bacteria culture

[0163] Take 200g of degerminated corn flour and 2.5g of yeast cells, after extrusion treatment, add water to make the volume to 0.7L, put it into a 3L seed tank, raise the temperature of the feed liquid to 50°C in advance, stir, and adjust the pH value of the feed liquid to 5.8- 6.0, add 0.09mL of high-temperature-resistant amylase, the addition amount is 0.6L / t corn flour dry basis, heat up to 100°C for liquefaction by passing steam, and keep warm for 20min. Then lower the temperature to 50-55°C, adjust the pH to 4.0-4.5, add high-efficiency liquid glucoamylase or compound glucoamylase 0.09ml, add 0.6L / t corn flour dry basis, add protease 0.03g, stir and saccharify at 50-55°C After 20 hours, the DE value of the saccharification solution was 95.3%.

[0164] Raise the temperature of the saccharification feed liquid to 121°C for 20 minutes, cool down to 28-35°C, adjust the volume of the feed liquid to 0.8L, adjust the pH to 5.5-6.5, insert Candida l...

Embodiment 3

[0171] 1. Bacteria culture

[0172] Take 200g of degerminated corn flour, 2.5g of yeast cells, add water to make the volume to 0.7L, put it into a 3L seed tank, raise the temperature of the feed liquid to 50°C in advance, stir, adjust the pH value of the feed liquid to 5.8-6.0, and add high-temperature-resistant starch Enzyme 0.09mL, additive amount 0.6L / t dry basis of corn flour, feed liquid is directly passed into steam and heated to 100°C for liquefaction, and kept for 20min. Then lower the temperature to 50-55°C, adjust the pH to 4.5, add 0.09mL of high-efficiency liquid glucoamylase or compound glucoamylase, add 0.03g of protease, add 0.6L / t corn flour dry basis, stir and saccharify at 50-55°C for 20h, The DE value of the saccharification liquid reaches 94.3%.

[0173] Raise the temperature of the saccharification feed liquid to 121°C for 15 minutes, cool down to 28-35°C, adjust the volume of the feed liquid to 0.8, adjust the pH to 5.5-6.5, insert Candida lipolytica CGM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com