Machine tool track swinging mechanism for processing ring-shaped patterns by using electric spark

An electric spark and ring technology, applied in the direction of metal processing machinery parts, metal processing equipment, driving devices, etc., can solve the problems of increasing auxiliary time, increasing manufacturing cost, and reducing processing efficiency, so as to reduce auxiliary time, reduce manufacturing cost, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

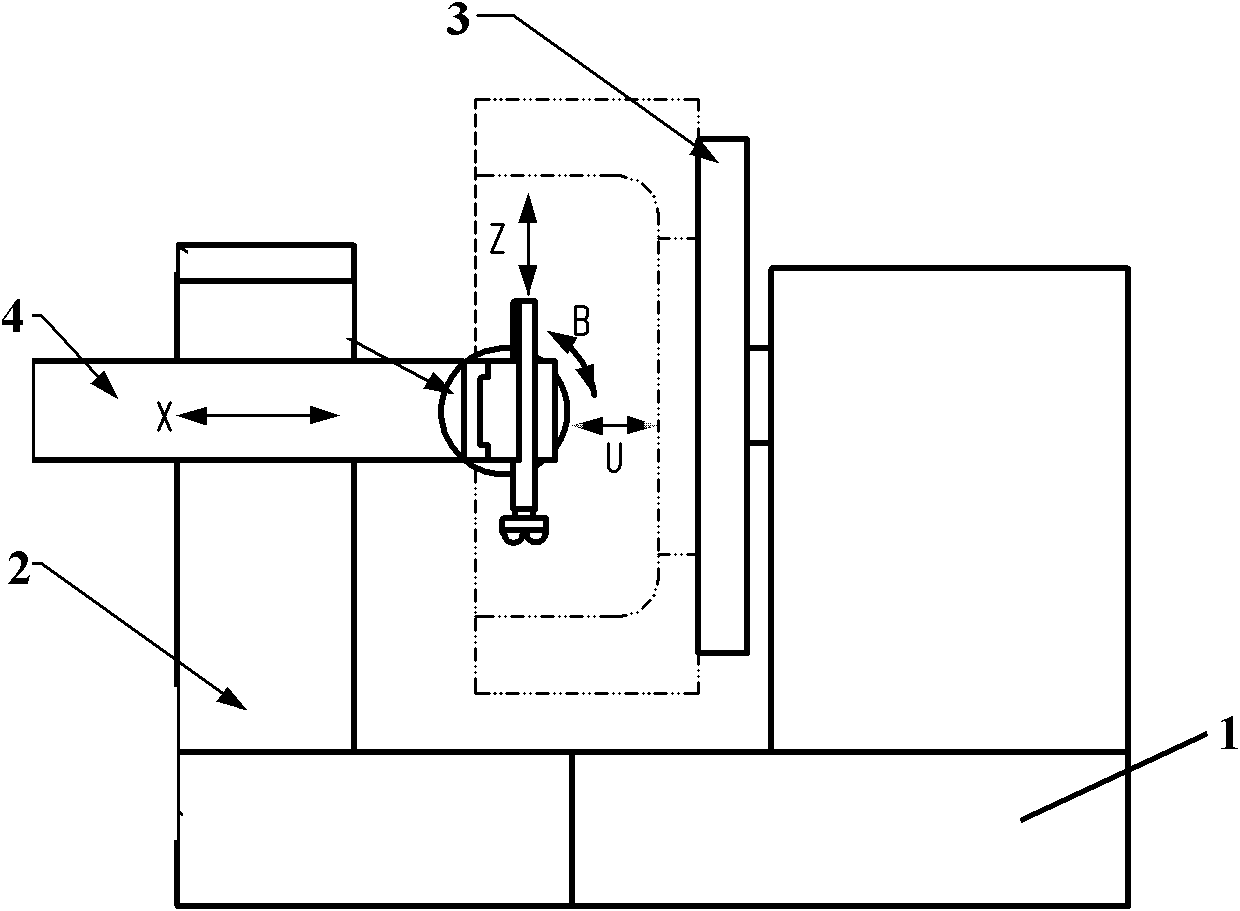

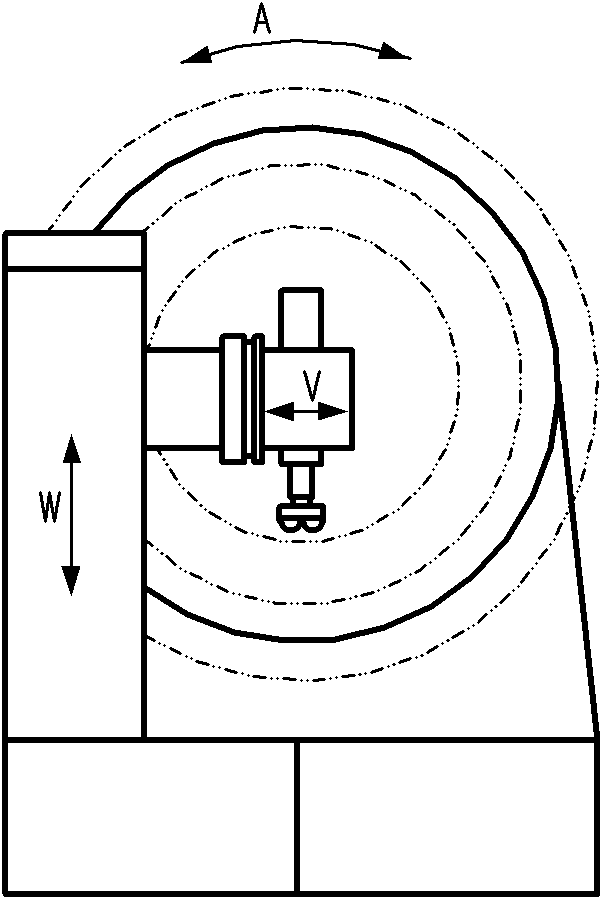

[0032] Embodiment 1: A machine tool trajectory rocking mechanism for EDM circular patterns, as attached Figure 1-4 As shown, it includes: a bed 1, a column cross arm 2 and an A-axis turntable 3 for placing workpieces to be processed. The column cross arm 2 is provided with an X-axis slider 4 that can move along the X-axis direction. The X The shaft slider 4 is connected with the column cross arm 2 through the first guide rail; a B-axis turntable 5 is fixed on one end of the X-axis slider 4, and a U-axis base 6 is fixedly installed on the surface of the B-axis turntable 5; a U-axis slider The block 7 is movably connected with the U-axis base 6 through the second guide rail, and the U-axis slider 7 can move along the X-axis direction;

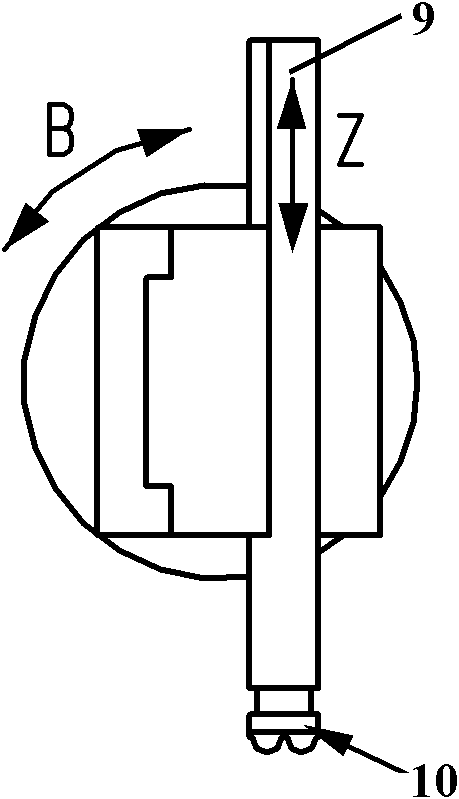

[0033] A V-axis slider 8 is movably connected with the U-axis slider 7 through the third guide rail, and the V-axis slider 8 can move along the Y-axis direction; a Z-axis slider 9 is movably connected with the V-axis slider through the fourth gu...

Embodiment 2

[0036] Embodiment 2: A machine tool trajectory rocking mechanism for EDM circular patterns, as attached Figure 5-8 As shown, it includes: a bed 1, a column cross arm 2 and an A-axis turntable 3 for placing workpieces to be processed. The column cross arm 2 is provided with an X-axis slider 4 that can move along the X-axis direction. The X The shaft slider 4 is connected with the column cross arm 2 through the first guide rail; a B-axis turntable 5 is fixed on one end of the X-axis slider 4, and a U-axis base 6 is fixedly installed on the surface of the B-axis turntable 5; a U-axis slider The block 7 is movably connected with the U-axis base 6 through the second guide rail, and the U-axis slider 7 can move along the X-axis direction;

[0037] A Z-axis slider 9 is movably connected with the U-axis slider 7 through the third guide rail, and the Z-axis slider 9 can move along the Z-axis direction; a V-axis slider 8 is movably connected with the Z-axis slider through the fourth gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com