Multi-phase flow measuring methods based on single-section impedance long-waist internal cone sensor

A measurement method and multi-phase flow technology, applied in the direction of fluid velocity measurement, mass flow measurement device, volume/mass flow generated by mechanical effects, etc., can solve calculation result errors, real-time performance of tomographic imaging technology, measurement accuracy and image quality The quality does not meet the requirements of industrial applications, and there are problems such as pulsation in the pressure signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058]The following detailed description of the steps of manufacturing and operating the present invention is intended to be described as an embodiment of the present invention, and is not the only form that can be manufactured or utilized. Other embodiments that can achieve the same function should also be included within the scope of the present invention .

[0059] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

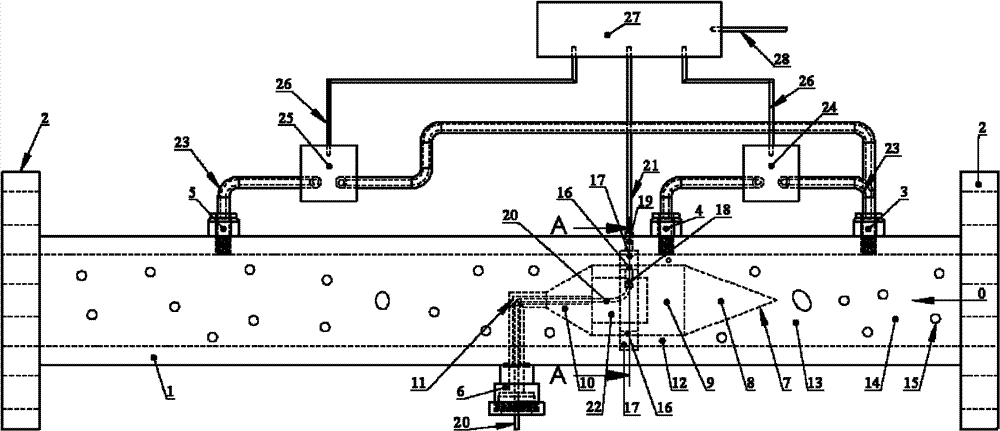

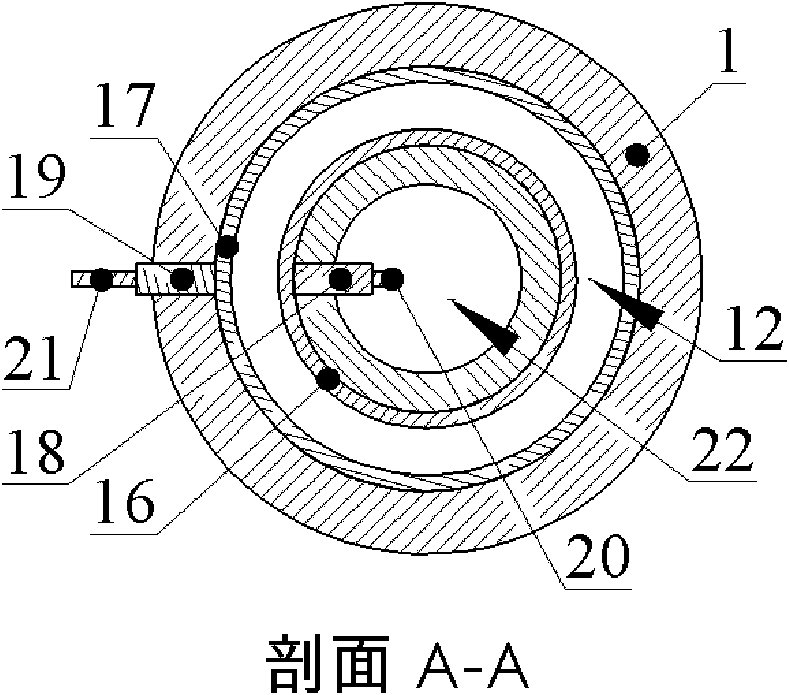

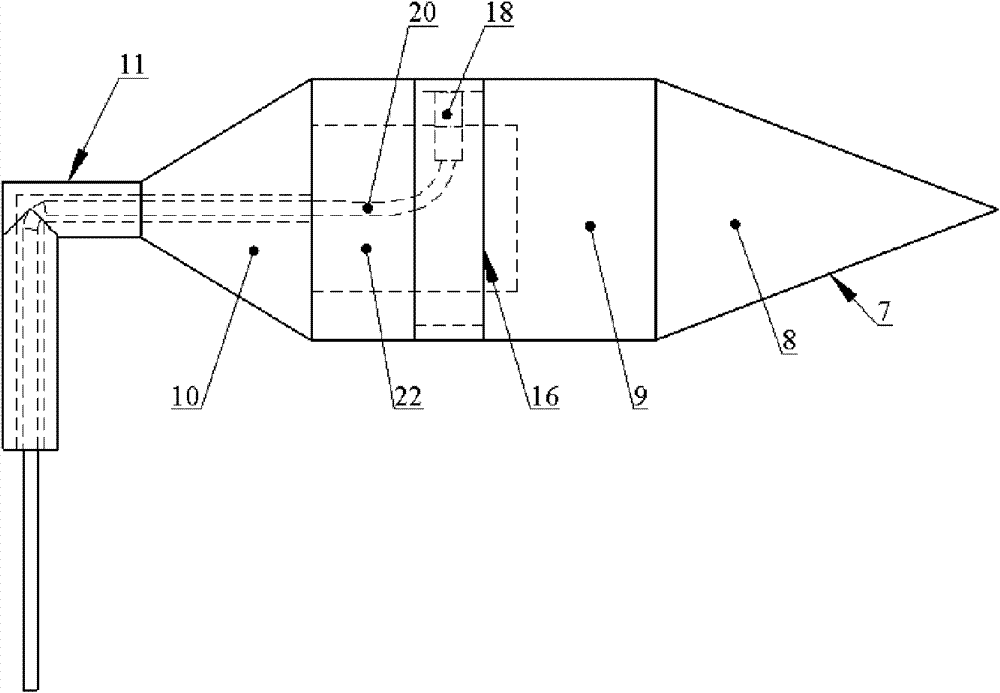

[0060] Reference attached Figure 1-4 , the measuring device that the measuring method of the present invention adopts comprises a pipeline 1 with flange 2 at both ends, a conical throttling member 7, three pressure-taking holes: upstream pressure-taking hole 3, middle pressure-taking hole 4, downstream pressure-taking hole Pressure-taking hole 5, two transmitters: systolic pressure drop differential pressure transmitter 24, permanent pressure loss differential pressure transmitter 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com