Circulation type rivet with rivet core

A circular, mandrel technology, applied to rivets and other directions, can solve problems such as weak holding force, and achieve the effects of saving energy, reducing use costs, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

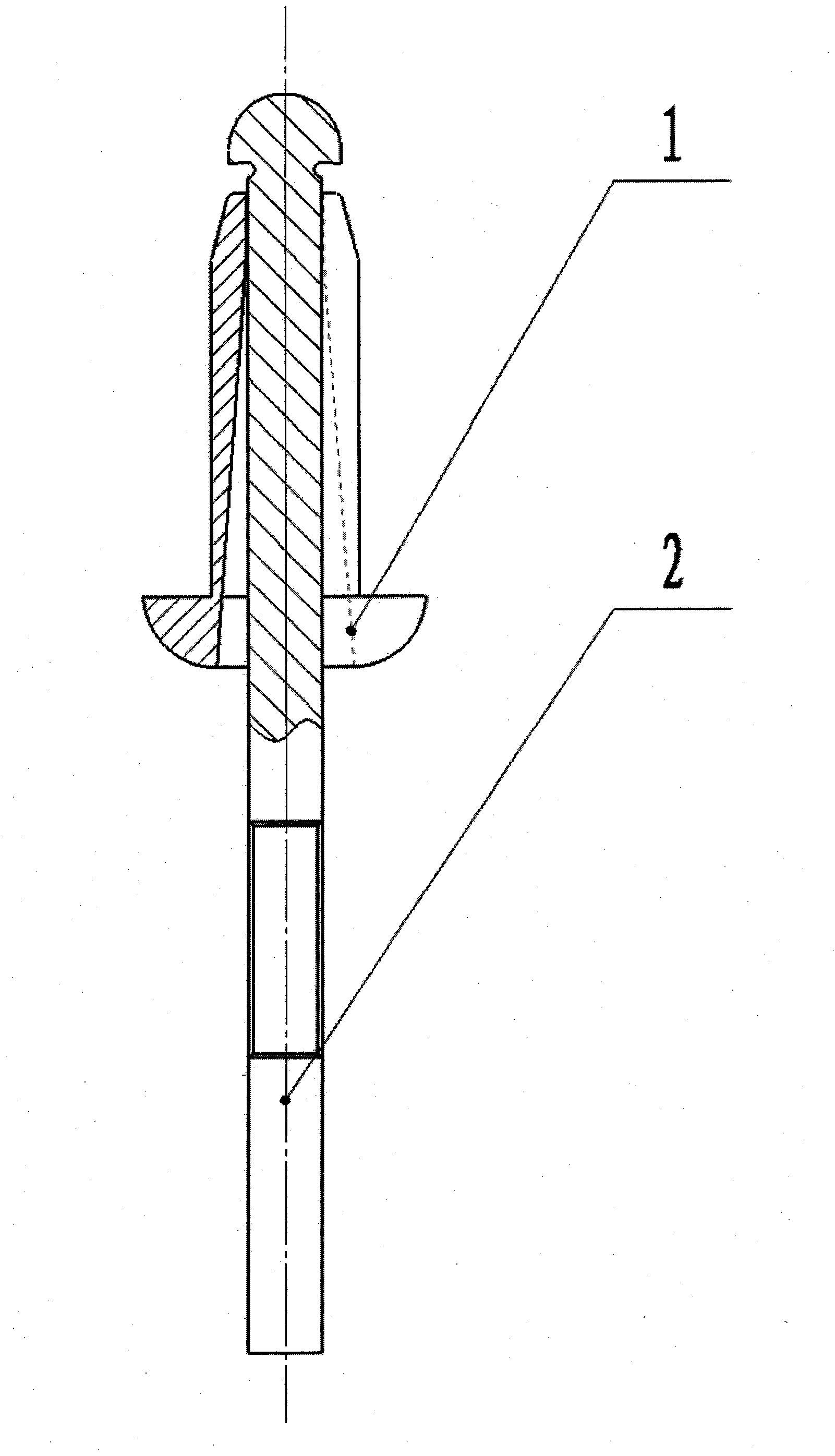

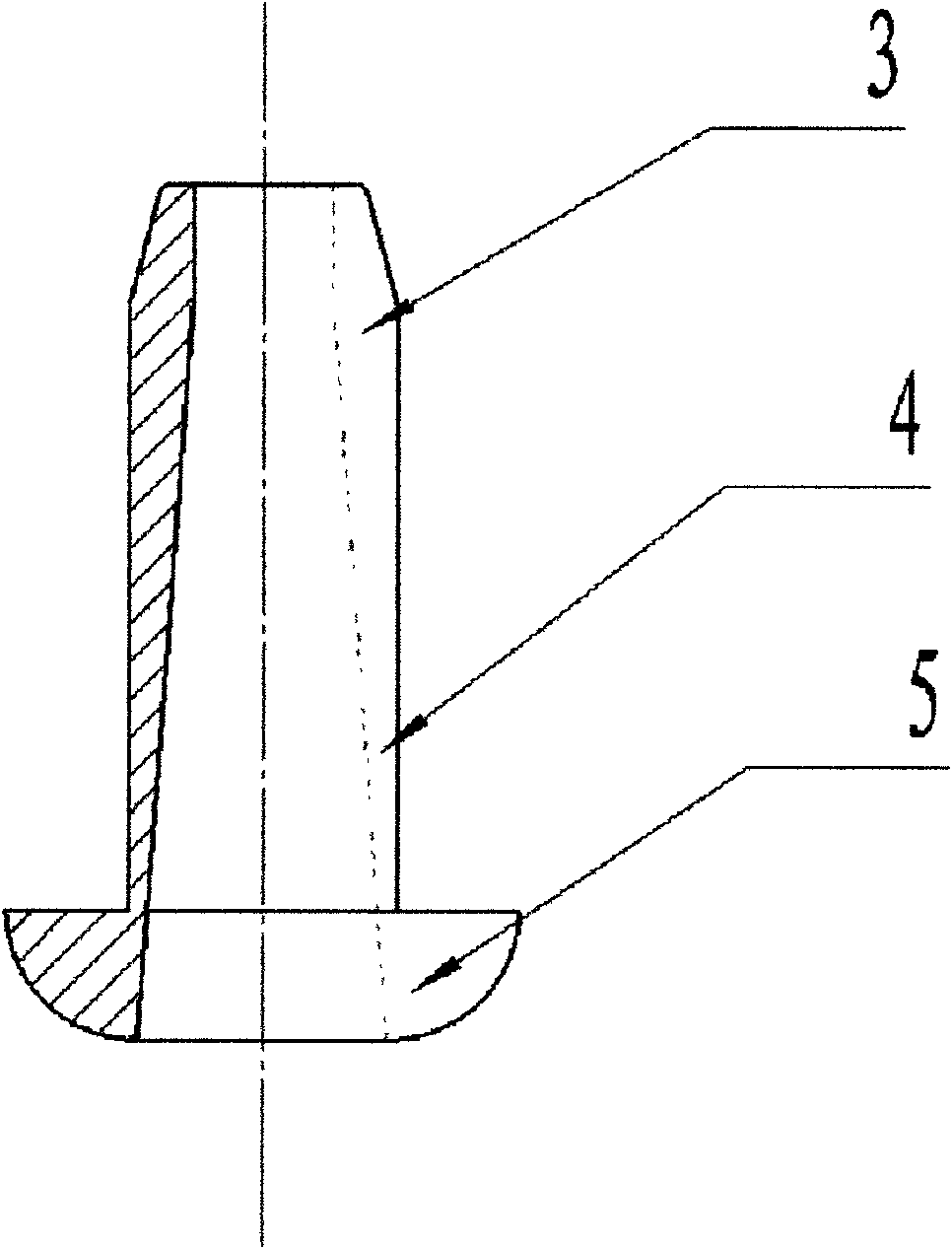

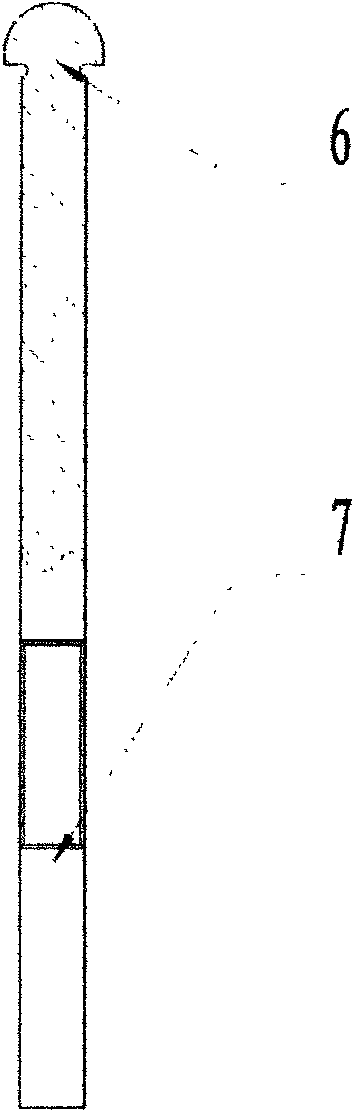

[0015] refer to Figure 1~3 , a nail core circulation type rivet, including nail body 1 and nail core 2 two parts, the nail body is divided into 3 sections of contact expansion section, compression contraction section 4 sections, nail body head 5 sections; nail core is divided into nail core head 6 intervals and 7 intervals on the tie rod.

[0016] Working principle: After the 5th section of the head of the rivet body is pressed against the riveted workpiece, because there is a threaded section in the 7th section of the tie rod, the nail mandrel is easy to apply external pulling force to the 7th section of the tie rod. The compression force is applied in the section. The structure of the nail body 3 section is a cone composed of an inner cylindrical surface and an outer conical surface; the nail body 4 section structure is an outer cylinder and an inner cone. Under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com